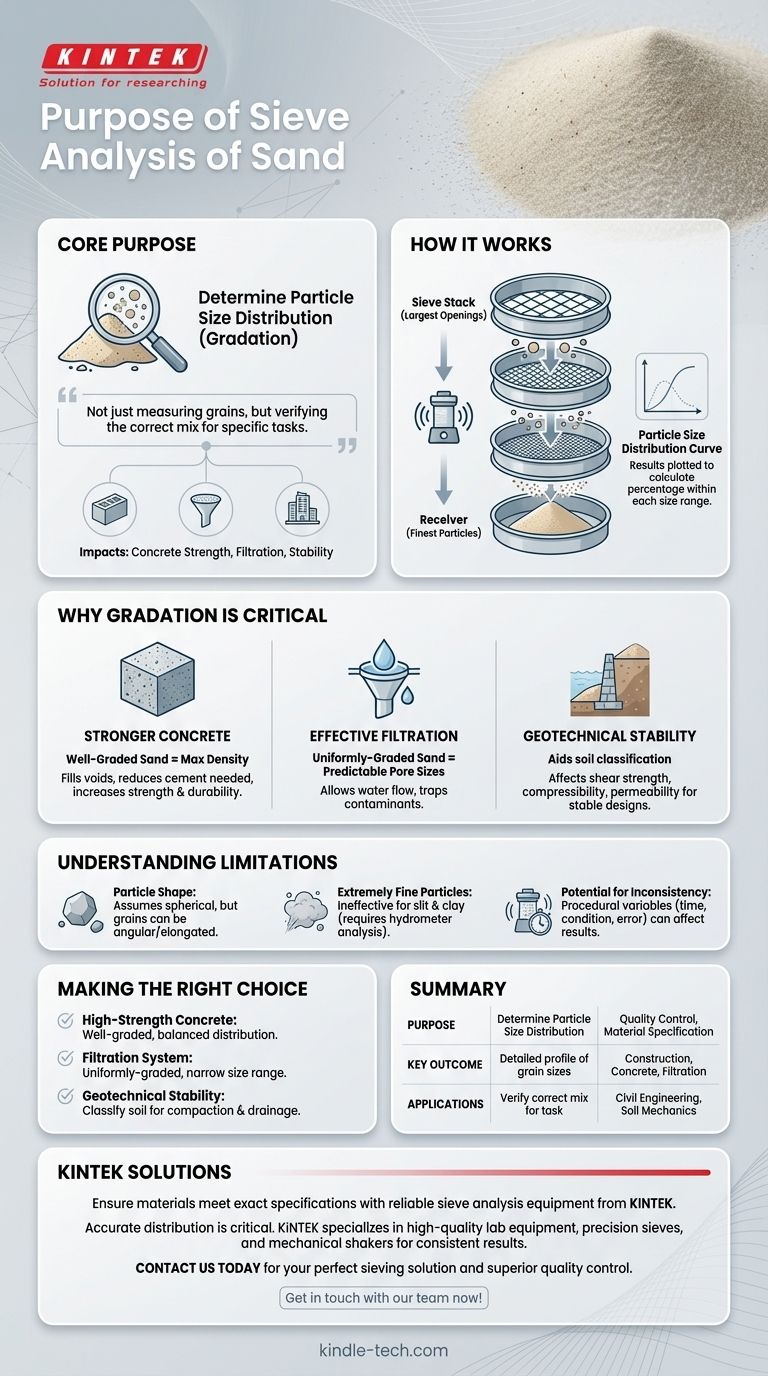

At its core, the purpose of a sieve analysis of sand is to determine its particle size distribution, often called its gradation. This foundational quality control test provides a detailed profile of the different sizes of grains within a sand sample, which is a critical factor for performance in industries ranging from construction to manufacturing.

The ultimate goal is not simply to measure sand grains, but to verify that the sand has the correct mix of particle sizes for a specific task. This "gradation" directly impacts the strength of concrete, the effectiveness of a filter, and the stability of a building foundation.

How Sieve Analysis Works

Sieve analysis is a straightforward, mechanical process for sorting particles by size. The methodology provides a clear picture of the material's physical makeup.

The Sieve Stack

The primary tool is a set of nested sieves with wire mesh screens. The sieve at the top of the stack has the largest openings, and each subsequent sieve below it has progressively smaller openings.

The Sorting Process

A carefully weighed sample of dry sand is placed in the top sieve. The entire stack is then agitated by a mechanical shaker, allowing particles to fall through the mesh screens until they reach a sieve with openings too small for them to pass.

The Role of the Receiver

At the very bottom of the stack is a solid pan called the receiver. It collects all the finest particles that pass through even the smallest mesh sieve, ensuring every part of the original sample is accounted for.

Analyzing the Results

After shaking is complete, the sand retained on each sieve is weighed. This data is used to calculate the percentage of the total sample that falls within each size range, often plotted on a graph known as a particle size distribution curve.

Why Gradation Is Critical

The specific mix of particle sizes dictates how the sand will behave. A sand sample is not just "sand"; its performance is defined by its gradation.

For Stronger Concrete

In concrete, the goal is to pack aggregates together as densely as possible. A well-graded sand, containing a good mix of coarse, medium, and fine particles, fills the voids between larger aggregates. This minimizes empty space, reduces the amount of expensive cement paste needed, and results in stronger, more durable, and less permeable concrete.

For Effective Filtration

Sand is a common medium for water filtration. In this application, a uniformly-graded sand (where most particles are the same size) is often required. This creates predictable pore spaces between the grains, allowing water to pass through while trapping contaminants of a specific size.

For Geotechnical Stability

Engineers use sieve analysis to classify soil and predict its behavior. The gradation of sand affects its shear strength, compressibility, and permeability—critical factors for designing stable foundations, embankments, and retaining walls.

Understanding the Limitations

While highly effective, sieve analysis is not without its trade-offs. Understanding its limitations is key to interpreting the results correctly.

Particle Shape Matters

The test fundamentally assumes particles are spherical. However, sand grains can be angular, flat, or elongated. A long, thin particle might pass through a mesh opening that it would have been retained on if it were cube-shaped, which can slightly skew the results.

Ineffective for Extremely Fine Particles

Sieve analysis is excellent for sand and gravel. It is not suitable for measuring the distribution of very fine particles like silt and clay, which can pass through the finest practical sieves. For these materials, other methods like hydrometer analysis are used.

Potential for Inconsistency

Results can be influenced by procedural variables. The duration and intensity of shaking, the condition of the sieves (clogged or damaged mesh), and operator error can all introduce minor variations in the final data.

Making the Right Choice for Your Goal

The "ideal" sand gradation is entirely dependent on its intended use. The sieve analysis provides the data needed to make an informed decision.

- If your primary focus is high-strength concrete: You need a well-graded sand with a balanced distribution across a wide range of particle sizes to ensure maximum density.

- If your primary focus is a filtration system: You most likely need a uniformly-graded sand where the vast majority of particles fall within a very narrow size range for consistent performance.

- If your primary focus is geotechnical stability: The analysis helps classify the soil to predict its compaction and drainage characteristics, ensuring it meets project specifications.

Ultimately, this simple test transforms sand from a generic commodity into a predictable engineering material with known properties.

Summary Table:

| Purpose | Key Outcome | Common Applications |

|---|---|---|

| Determine Particle Size Distribution | Provides a detailed profile of grain sizes | Quality Control, Material Specification |

| Ensure Optimal Concrete Strength | Identifies well-graded sand for maximum density | Construction, Concrete Production |

| Guarantee Effective Filtration | Verifies uniformly-graded sand for consistent pore size | Water Treatment, Industrial Filtration |

| Assess Geotechnical Stability | Classifies soil for foundation and embankment design | Civil Engineering, Soil Mechanics |

Ensure your materials meet exact specifications with reliable sieve analysis equipment from KINTEK.

Accurate particle size distribution is critical for the success of your projects. KINTEK specializes in high-quality lab equipment, including precision sieves and mechanical shakers, designed to deliver consistent, trustworthy results for your laboratory's needs.

Contact us today to find the perfect sieving solution for your sand and aggregate testing requirements. Let our experts help you achieve superior quality control.

Get in touch with our team now!

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

People Also Ask

- What is the primary purpose of an industrial grinder and 400-mesh sieve for coconut shell powder? Achieve Uniformity.

- What size are laboratory sieve mesh? Master Frame Diameter vs. Mesh Opening for Accurate Particle Analysis

- What are the limitations of sieving method? Understanding Accuracy and Particle Size Challenges

- What is the primary function of fine-mesh test sieves? Master Natural Mordenite Purification

- What is the mesh size of a sieve? A Guide to Particle Size and Sieve Selection

- What are the advantages and disadvantages of the sieve method? A Practical Guide to Particle Size Analysis

- What are the standard sieve sizes used in food industry? A Guide to ASTM, Tyler, and ISO Standards

- What is the application of sieving method in pharmacy? Ensure Drug Quality, Safety, and Efficacy