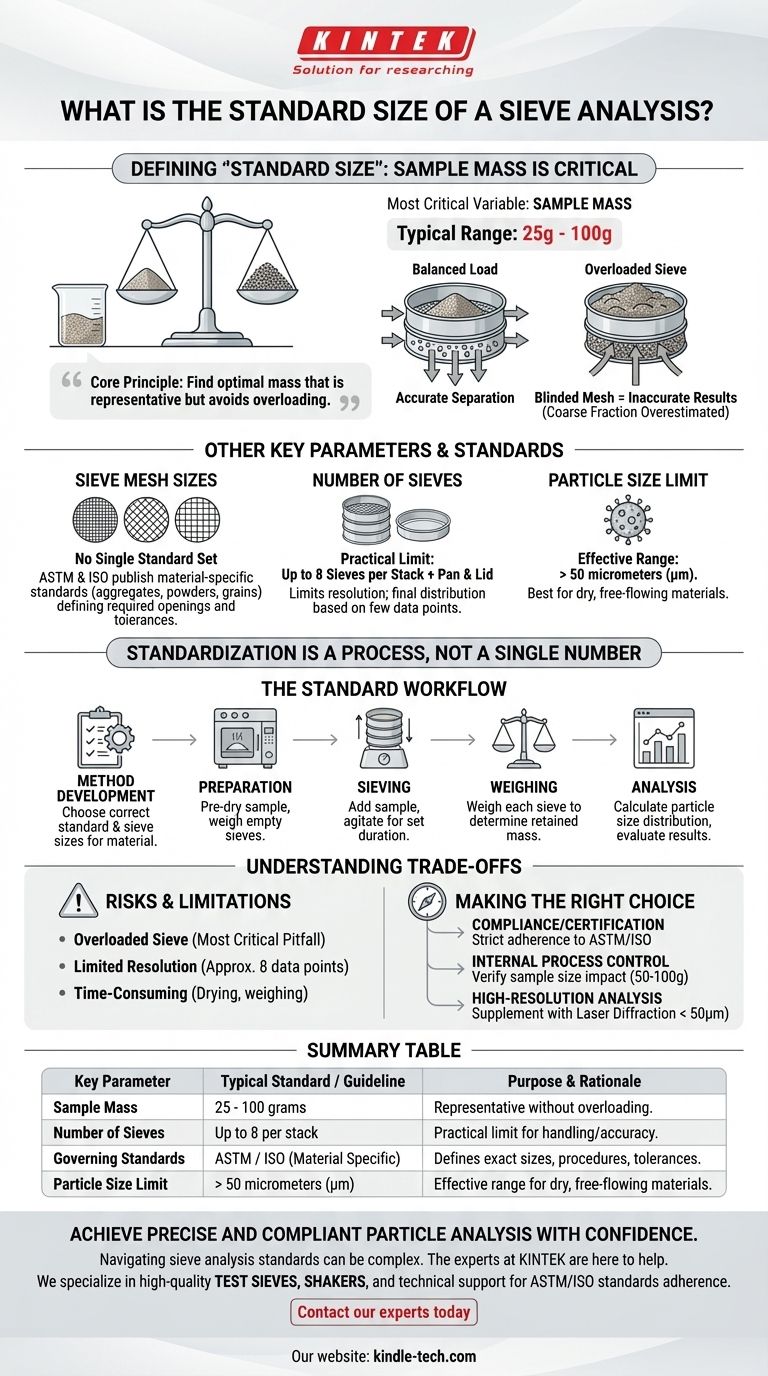

In sieve analysis, there is no single universal "standard size," but the term most often refers to the sample weight. For most applications, a sample mass between 25 and 100 grams is the generally accepted starting point. The precise amount, however, depends entirely on the characteristics of the material being tested and the specific industry standard (like ASTM or ISO) you are required to follow.

The core principle of sieve analysis is not finding one "standard size," but determining the optimal sample mass that is large enough to be representative of the bulk material yet small enough to ensure every particle has a chance to pass through the sieve openings. Overloading a sieve is the most common source of inaccurate results.

Defining "Standard Size" in Sieve Analysis

The term "size" can be ambiguous. In the context of a sieve analysis, it refers to several distinct parameters, each governed by standards and best practices.

Sample Mass (The Most Critical Variable)

The most critical "size" is the mass of the material sample you test. A range of 25g to 100g is a common recommendation.

Using a sample that is too large can blind the sieve mesh. This prevents individual particles from making contact with the screen, leading to an inaccurate measurement where coarse fractions are overestimated.

The optimal mass is found by testing progressively smaller samples (e.g., 200g, 100g, 50g) until the results stabilize. This confirms you have found the maximum sample load that still allows for accurate separation.

Sieve Mesh Sizes (The Measurement Standard)

There is no single standard set of mesh sizes for all tests. Instead, organizations like ASTM and ISO publish over a hundred different standards specific to materials like aggregates, powders, and grains.

These standards dictate which sieve mesh openings are required for that specific material. They also define the manufacturing tolerances for the "test grade" sieve cloth to ensure uniformity and comparability between labs.

Number of Sieves in a Stack

A standard sieve stack typically consists of a maximum of 8 sieves, plus a bottom pan and a lid.

This practical limit means a standard analysis will yield a particle size distribution curve based on only a few data points. The granularity of your final result is therefore inherently limited by the number of sieves you can physically stack.

Standardization is a Process, Not a Single Number

Achieving a "standard" sieve analysis result comes from following a standardized method, not from using one magic number for sample size.

The Role of ASTM and ISO Standards

Authoritative standards from bodies like ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization) are the ultimate source of truth.

These documents provide a complete procedure, detailing everything from sample preparation and drying to sieving time, shaker motion, and how to report the final results. Adhering to the correct standard for your material is essential for certification and quality control.

The Standard Workflow

While specifics vary, the general standardized process involves:

- Method Development: Choosing the correct standard and sieve sizes for your material.

- Preparation: Pre-drying or conditioning the sample and accurately weighing the empty sieves.

- Sieving: Adding the pre-weighed sample to the top sieve and agitating the stack for a set duration.

- Weighing: Weighing each sieve again to determine the mass of the fraction retained on it.

- Analysis: Calculating the particle size distribution and evaluating the results.

Understanding the Trade-offs and Limitations

While sieve analysis is a foundational technique, it's important to recognize its inherent limitations to avoid misinterpreting results.

The Risk of an Overloaded Sieve

This is the most critical pitfall. If you use too much material, the layer of particles on the mesh will be too thick. Particles that should have passed through will be trapped, skewing your results toward a coarser distribution.

Limited Resolution

With a maximum of about 8 sieves, your final distribution curve is an approximation based on a small number of data points. For applications requiring a highly detailed understanding of particle distribution, other methods may be necessary.

Material and Time Constraints

Sieve analysis is generally effective only for dry, free-flowing particles larger than about 50 micrometers (µm). The process of drying, weighing, sieving, and re-weighing can also be significantly more time-consuming than automated particle analysis techniques.

Making the Right Choice for Your Analysis

Your goal determines how you should approach standardization.

- If your primary focus is compliance or certification: You must identify and strictly adhere to the specific ASTM, ISO, or other industry standard designated for your exact material.

- If your primary focus is internal process control: Start with a sample in the 50-100g range and verify that using a smaller sample does not significantly alter the percentage of material retained on each sieve.

- If your primary focus is high-resolution analysis: Recognize the limitations of sieving for fine powders and consider supplementing your analysis with methods like laser diffraction for particles below 50 µm.

Ultimately, a reliable and repeatable sieve analysis is achieved by following a standardized and methodical process, not by relying on a single sample size.

Summary Table:

| Key Parameter | Typical Standard / Guideline | Purpose & Rationale |

|---|---|---|

| Sample Mass | 25 - 100 grams | Ensures the sample is representative without overloading the sieves. |

| Number of Sieves | Up to 8 sieves per stack | Practical limit for handling and accurate separation. |

| Governing Standards | ASTM / ISO (Material Specific) | Defines exact sieve sizes, procedures, and tolerances for reliable, comparable data. |

| Particle Size Limit | > 50 micrometers (µm) | Effective range for dry, free-flowing materials using this method. |

Achieve precise and compliant particle analysis with confidence.

Navigating the specifics of sieve analysis standards for your material can be complex. The experts at KINTEK are here to help. We specialize in providing the right lab equipment, including high-quality test sieves and shakers, and the technical support to ensure your sieving process is optimized for accuracy and adherence to ASTM or ISO standards.

Let KINTEK support your laboratory's quality control.

Contact our experts today to discuss your specific application and ensure your sieve analysis is perfectly standardized.

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

- Laboratory Vortex Mixer Orbital Shaker Multifunctional Rotation Oscillation Mixer

People Also Ask

- What is an example of sieving in the laboratory? Master Particle Size Analysis for Quality Control

- What are the uses of sieves in pharmacy? Ensure Drug Safety and Efficacy with Precise Particle Control

- What is sieve screening? A Guide to Particle Size Distribution Analysis

- How does a sieve test work? A Guide to Precise Particle Size Distribution Analysis

- What is a laboratory sieve? A Guide to Precise Particle Size Analysis

- What are the different types of test sieves? Choose the Right Sieve for Accurate Particle Analysis

- What are the limitations of sieving method? Understanding Accuracy and Particle Size Challenges

- What is the purpose of using a 500-mesh sieve for LLZTO powder? Ensure Battery Safety with Precise Particle Control