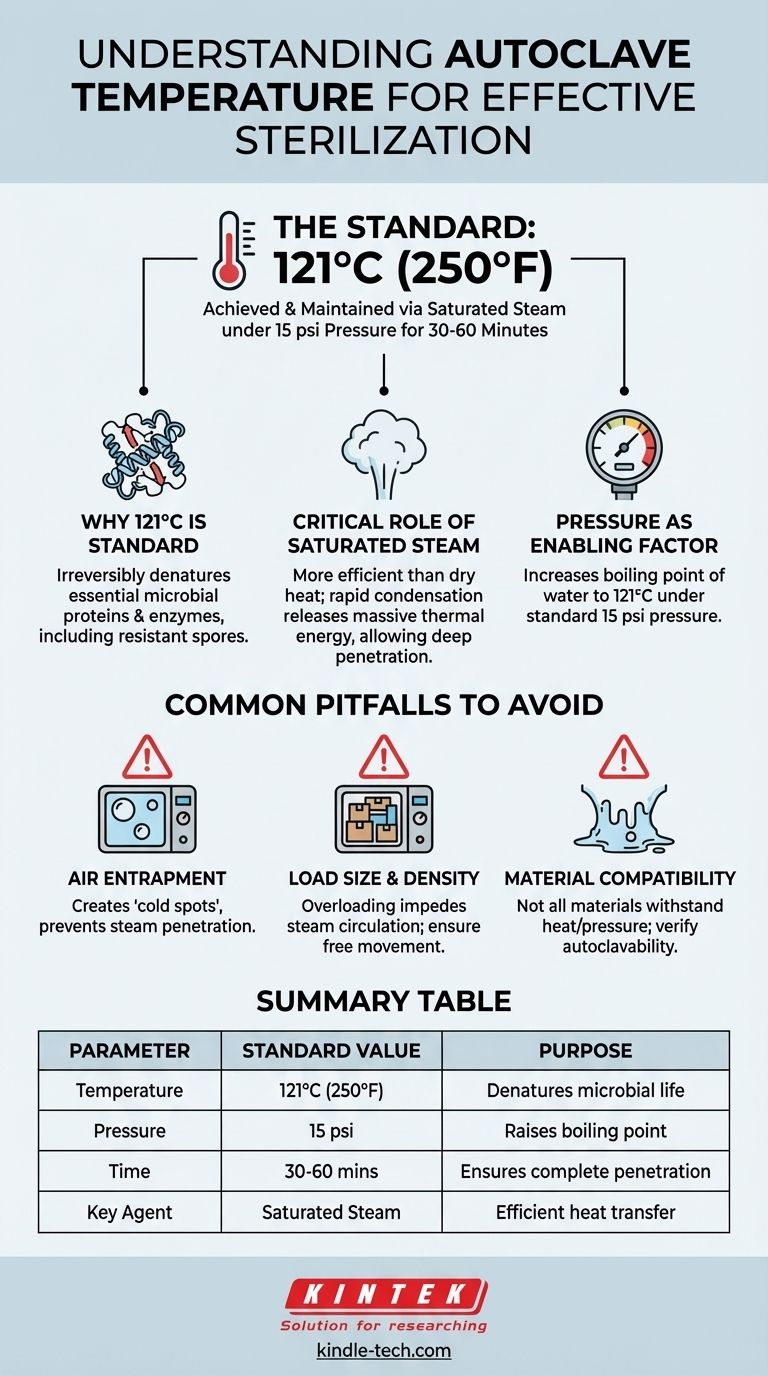

The standard temperature for effective steam sterilization in an autoclave is 121° C (250° F). This temperature is achieved and maintained by using saturated steam under a pressure of approximately 15 pounds per square inch (psi). The specific duration of the cycle, typically between 30 and 60 minutes, is determined by the size and type of the items being sterilized.

While 121°C is the critical temperature benchmark, true sterilization is not achieved by temperature alone. It is the result of a precise interplay between temperature, saturated steam, pressure, and time, all working together to ensure the complete elimination of all microbial life.

The Core Principles of Steam Sterilization

To understand why simply setting a temperature is not enough, you must understand how an autoclave actually works. It's a system where multiple factors are codependent.

Why 121°C (250°F) is the Standard

At this temperature, the essential proteins and enzymes that make up microorganisms, including highly resistant bacterial spores, are irreversibly denatured and destroyed. This temperature provides a reliable margin of safety for killing even the most heat-resistant life forms.

The Critical Role of Saturated Steam

An autoclave does not use dry heat; it uses saturated steam. This is water vapor held at the boiling point for a given pressure. When this steam makes contact with a cooler item, it condenses rapidly, releasing a massive amount of thermal energy. This process is far more efficient at transferring heat than hot air, allowing for rapid and deep penetration into the load.

Pressure as the Enabling Factor

Under normal atmospheric pressure, water boils at 100°C (212°F). To reach the necessary sterilization temperature of 121°C, the pressure inside the autoclave chamber must be increased. The standard pressure of 15 psi above atmospheric pressure is precisely what is needed to raise the boiling point of water to 121°C, creating the required saturated steam environment.

Time: Ensuring Complete Penetration

The sterilization time, typically 30 to 60 minutes, is the period required for the saturated steam to penetrate the entire load and hold all items at 121°C. Shorter times may be sufficient for simple glass or metal tools, while longer times are necessary for denser materials, wrapped instrument packs, or liquids.

Common Pitfalls to Avoid

Achieving the correct temperature and pressure on the autoclave's gauges does not guarantee sterilization. Several common errors can lead to a failed cycle.

The Danger of Air Entrapment

This is the most critical factor in failed sterilization. If air is trapped in the chamber or within a package, it creates "cold spots." Steam cannot displace this trapped air, so these areas will never reach the required 121°C, even if the autoclave's thermometer reads correctly. Proper loading and, in some models, vacuum cycles are essential to remove all air.

Load Size and Density Matter

Overloading the autoclave or packing items too tightly prevents steam from circulating freely. Steam must make direct contact with every surface to be sterilized. A cycle that is effective for a light load will fail for a dense load if the time is not extended to allow for complete steam penetration.

Forgetting Material Compatibility

While not a temperature issue, it's a critical safety consideration. Not all materials can withstand the heat and pressure of an autoclave. Certain plastics may melt, and sharp instruments can be dulled. Always verify that your materials are autoclavable.

Making the Right Choice for Your Goal

Achieving guaranteed sterility requires you to consider your specific load and apply the right parameters.

- If your primary focus is sterilizing simple, unwrapped items (glassware, metal tools): A standard cycle of 121°C at 15 psi for 30 minutes is typically sufficient, provided you load the items loosely to allow for steam circulation.

- If your primary focus is sterilizing complex loads (wrapped instruments, biohazard bags, liquids): You must increase the cycle time (often to 60 minutes or more) to ensure full heat penetration and use a chemical or biological indicator to verify that sterilizing conditions were met in the center of the load.

- If your primary focus is safety and compliance in a clinical or research setting: You must strictly follow validated protocols for your specific autoclave model and load types, including regular maintenance and the mandatory use of sterility indicators in every cycle.

Understanding these interconnected principles is the key to moving from simply operating an autoclave to ensuring true sterility.

Summary Table:

| Parameter | Standard Value | Purpose |

|---|---|---|

| Temperature | 121°C (250°F) | Denatures and destroys all microbial life, including spores. |

| Pressure | 15 psi | Raises the boiling point of water to create saturated steam. |

| Time | 30-60 minutes | Ensures complete steam penetration and heat exposure for the entire load. |

| Key Agent | Saturated Steam | Efficiently transfers heat by condensing on surfaces. |

Achieve Uncompromising Sterility with KINTEK

Guaranteeing the safety of your laboratory work requires more than just reaching a temperature—it demands a deep understanding of the entire sterilization process. KINTEK specializes in providing reliable autoclaves and expert support to ensure your lab meets the highest standards of sterility and compliance.

We help you:

- Select the right autoclave for your specific load types, from simple glassware to complex wrapped instruments.

- Optimize your cycles to prevent common pitfalls like air entrapment and incomplete penetration.

- Maintain compliance with validated protocols for clinical, research, and industrial applications.

Let our expertise in lab equipment become your advantage. Contact KINTEK today to find the perfect sterilization solution for your laboratory's needs.

Visual Guide

Related Products

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

People Also Ask

- What role does an autoclave play in the acid treatment for microalgae disruption? Unlock High-Yield Cell Pretreatment

- What is the life expectancy of an autoclave machine? Maximize Your Investment with Proper Care

- What types of items and materials can be processed in a laboratory autoclave? Essential Guide for Lab Safety

- What is the necessity of using an autoclave for pre-treating culture media? Ensure Accurate Ag2O/TiO2 Testing

- What critical environmental conditions does a laboratory autoclave provide for evaluating wear resistance? - KINTEK