At its core, a blown film machine is a specialized manufacturing line that transforms polymer resin pellets into a continuous, thin plastic film. This process is the backbone of the flexible packaging industry, responsible for producing essential items like shrink wrap, stretch films for pallets, shopping bags, and films used for lamination and food packaging.

The true value of the blown film process lies not just in what it makes, but how it makes it. By inflating a tube of molten plastic like a balloon, the machine stretches the material in two directions simultaneously, creating a film that is uniquely strong, versatile, and cost-effective for high-volume applications.

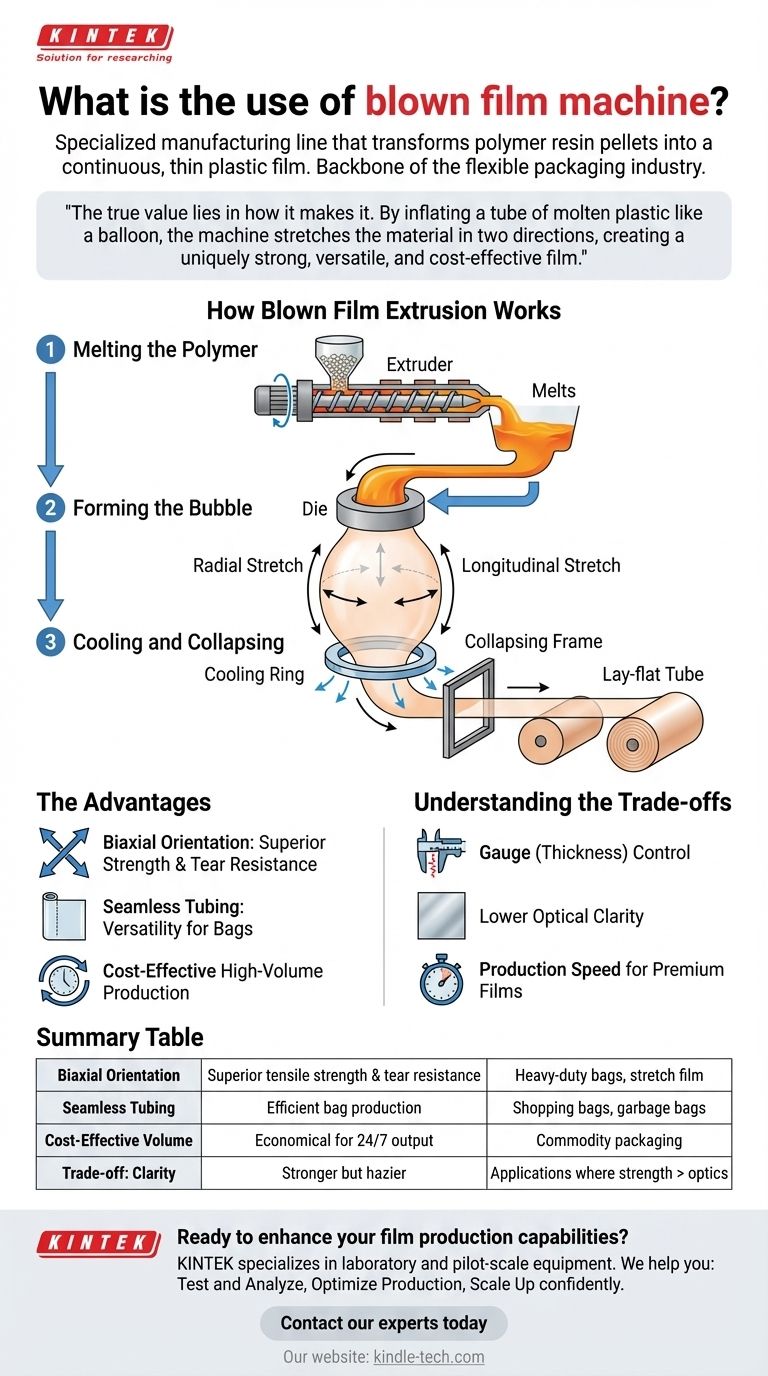

How Blown Film Extrusion Works

Understanding the process reveals why the resulting film has such desirable properties for packaging. The entire operation is a continuous, vertically oriented production line.

Step 1: Melting the Polymer

The process begins with solid polymer resin pellets, typically polyethylene (PE), which are fed into a heated barrel containing a rotating screw. This device, known as an extruder, melts and pressurizes the plastic, transforming it into a consistent, molten material.

Step 2: Forming the Bubble

The molten plastic is then forced upwards through a circular die. As the plastic exits the die in the shape of a thin-walled tube, air is injected into the center of the tube. This internal air pressure inflates the tube, stretching it both radially (outwards) and longitudinally (upwards). This is the "blowing" step that gives the process its name.

Step 3: Cooling and Collapsing

High-speed air flows across the outside of this inflated bubble, rapidly cooling and solidifying the plastic. The bubble, which can be many meters tall, is then guided through a collapsing frame that flattens it into a double-layered sheet. This flat "lay-flat" tube is then wound onto large rolls.

The Advantages of the Blown Film Method

The unique manufacturing process imparts specific characteristics that make blown film a dominant technology in its field.

Biaxial Orientation: The Source of Strength

The most significant advantage is biaxial orientation. By stretching the film in two directions at once (outward and upward), the polymer molecules align in a crisscross pattern. This provides the film with balanced and superior tensile strength, tear resistance, and toughness compared to a film that is only stretched in one direction.

Seamless Tubing: Versatility for Bags

Because the process starts with a tube, it naturally creates a seamless product. This is incredibly efficient for producing bags, as the sides of the tube become the sides of the bag, requiring only cuts and seals at the top and bottom.

Cost-Effective High-Volume Production

Blown film lines are designed for continuous, 24/7 operation. This makes them highly economical for producing the massive quantities of commodity films required by the global packaging and agricultural industries.

Understanding the Trade-offs

No single process is perfect for every application. Objectivity requires acknowledging the limitations of blown film extrusion, especially when compared to its primary alternative, cast film extrusion.

Gauge (Thickness) Control

Achieving perfectly uniform film thickness, or gauge, can be more challenging with blown film than with cast film. The cooling and inflation dynamics can introduce slight variations across the width of the film.

Lower Optical Clarity

The relatively slow, air-cooling process in blown film allows for larger crystal structures to form in the polymer. This results in a film that is typically stronger but also hazier and less transparent than cast film, which is cooled rapidly on a chill roll.

Production Speed for Premium Films

While excellent for commodity films, the cooling process can be a bottleneck. For applications demanding exceptional clarity and perfect gauge, the cast film process can often achieve higher production speeds.

Making the Right Choice for Your Application

Selecting the right film manufacturing process depends entirely on the end-use requirements of the product.

- If your primary focus is strength, toughness, and bag production: Blown film is the superior choice due to its inherent biaxial orientation and seamless tube format.

- If your primary focus is high optical clarity and uniform thickness: You should investigate cast film extrusion, as its rapid cooling process delivers better transparency.

- If your primary focus is cost-effective commodity packaging: Blown film offers an unparalleled balance of performance and production efficiency for items like trash bags and construction sheeting.

Ultimately, the blown film machine is a cornerstone of modern manufacturing, enabling the efficient production of strong and versatile plastic films that are essential to global commerce.

Summary Table:

| Feature | Advantage | Key Application |

|---|---|---|

| Biaxial Orientation | Superior tensile strength & tear resistance | Heavy-duty bags, stretch film |

| Seamless Tubing | Efficient bag production with fewer seals | Shopping bags, garbage bags |

| Cost-Effective Volume | Economical for 24/7 high-volume output | Commodity packaging, agricultural film |

| Trade-off: Clarity | Stronger but hazier than cast film | Applications where strength > optics |

Ready to enhance your film production capabilities?

At KINTEK, we specialize in providing robust laboratory and pilot-scale equipment for polymer research and development. Whether you are testing new resin formulations or optimizing your blown film process, our solutions deliver the precision and reliability you need.

We help you:

- Test and Analyze material properties for your specific application.

- Optimize Production parameters for strength, clarity, and efficiency.

- Scale Up confidently from lab to production.

Let's discuss your project. Contact our experts today to find the perfect equipment for your laboratory's needs!

Visual Guide

Related Products

- Lab Blown Film Extrusion Three Layer Co-Extrusion Film Blowing Machine

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- Small Lab Rubber Calendering Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

People Also Ask

- Why are high-pressure hydraulic presses necessary for UHMWPE? Mastering Zero-Flow Material Processing

- What are the disadvantages of the extrusion process? High Costs and Geometric Limits Explained

- What is the cost of blown film extrusion? From $20K to High-End Systems

- What is the process of extrusion blowing? A Guide to Efficient Hollow Plastic Part Production

- What is the process of double extrusion? Create Integrated Multi-Material Components