In the laboratory, sieving is the fundamental method used to separate granular materials based on particle size. Its primary purpose is to determine the particle size distribution of a sample, grade materials to specific size fractions, and measure impurity levels.

The core function of laboratory sieving is not simply sorting particles; it is about imposing control and generating data. It ensures that materials meet precise specifications, which is a non-negotiable requirement for reliable research, quality control, and manufacturing.

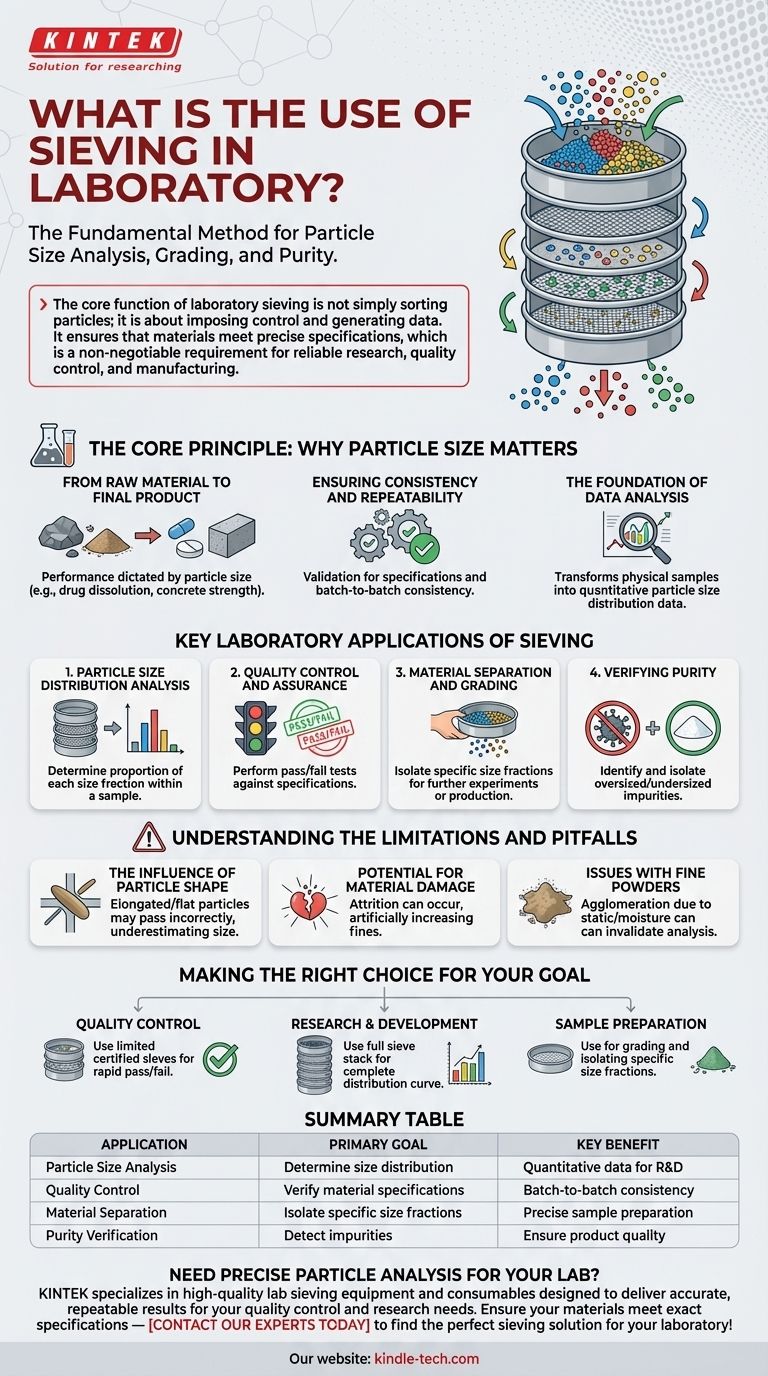

The Core Principle: Why Particle Size Matters

Understanding the size of particles within a material is critical because size directly influences a substance's physical and chemical properties. Sieving provides the essential data and control needed to manage these properties.

From Raw Material to Final Product

A material's performance is often dictated by the size of its constituent particles. For example, the dissolution rate of a pharmaceutical drug or the strength of concrete depends on the precise size distribution of its powders and aggregates.

Ensuring Consistency and Repeatability

Sieving is a cornerstone of quality control. It validates that both incoming raw materials and outgoing finished products adhere to required specifications, ensuring batch-to-batch consistency.

The Foundation of Data Analysis

Sieving transforms a physical sample into a quantitative data set. This particle size distribution analysis is a foundational technique used in research and development to characterize new materials and optimize processes.

Key Laboratory Applications of Sieving

While the principle is simple, its application is varied and critical across many scientific and industrial fields.

Particle Size Distribution Analysis

This is the most common application. A stack of sieves with progressively smaller mesh openings is used to sort a sample into different size fractions, allowing analysts to determine the proportion of each size within the material.

Quality Control and Assurance

Labs use sieving to perform pass/fail tests. A material might be tested to ensure that no more than a certain percentage of its particles are larger or smaller than a specified size.

Material Separation and Grading

Sieving is also used for preparation. Researchers may need to isolate particles of a specific size range from a mixed sample for use in further experiments or production processes.

Verifying Purity

The technique can effectively identify contamination. By sieving a sample, oversized or undersized impurities can be quickly isolated and measured, confirming the purity of the material.

Understanding the Limitations and Pitfalls

While powerful, sieving is a mechanical process with inherent trade-offs that an expert must consider to ensure accurate results.

The Influence of Particle Shape

Sieving analysis assumes particles are perfect spheres. Elongated or flat particles can pass through mesh openings end-on or diagonally, leading to an underestimation of their true size.

Potential for Material Damage

The agitation required for sieving can cause fragile particles to break apart (attrition). This can skew results by artificially creating more fine particles than were present in the original sample.

Issues with Fine Powders

Very fine powders are susceptible to agglomeration, where particles clump together due to static electricity or moisture. These clumps behave like larger particles, preventing them from passing through the correct sieve and invalidating the analysis.

Making the Right Choice for Your Goal

The specific sieving method and interpretation of results depend entirely on your objective.

- If your primary focus is quality control: Use a limited set of certified sieves that correspond directly to your product's specifications to get a rapid pass/fail result.

- If your primary focus is research and development: Use a full stack of sieves with a wide range of mesh sizes to generate a complete particle size distribution curve for detailed material characterization.

- If your primary focus is sample preparation: Use sieving simply to grade a material, isolating the desired size fraction for a subsequent experiment or process.

Ultimately, mastering sieving is about understanding and controlling the physical properties of your materials to guarantee a predictable and reliable outcome.

Summary Table:

| Application | Primary Goal | Key Benefit |

|---|---|---|

| Particle Size Analysis | Determine size distribution | Quantitative data for R&D |

| Quality Control | Verify material specifications | Batch-to-batch consistency |

| Material Separation | Isolate specific size fractions | Precise sample preparation |

| Purity Verification | Detect impurities | Ensure product quality |

Need precise particle analysis for your lab? KINTEK specializes in high-quality lab sieving equipment and consumables designed to deliver accurate, repeatable results for your quality control and research needs. Ensure your materials meet exact specifications — contact our experts today to find the perfect sieving solution for your laboratory!

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Multifunctional Small Speed-Adjustable Horizontal Mechanical Shaker for Lab

People Also Ask

- What is the purpose of using a laboratory grinder with specific mesh sieves for oat straw? Optimize Pellet Quality

- What are the practical applications of sieve analysis? Ensure Material Quality from Construction to Food

- What are sieve analysis used for? A Guide to Particle Size Distribution Testing

- What is a sieve in a laboratory? A Guide to Precision Particle Size Analysis

- Why is sieve analysis important in construction industry? Ensure Material Strength & Cost-Efficiency

- Why is sieve test important? Ensure Product Quality and Performance with Precise Particle Analysis

- What are the sieve used in laboratory? A Guide to Choosing the Right Sieve for Accurate Particle Analysis

- Why must ultra-fine ceramic powders be processed with a standard sieve? Key to Defect-Free Sintering