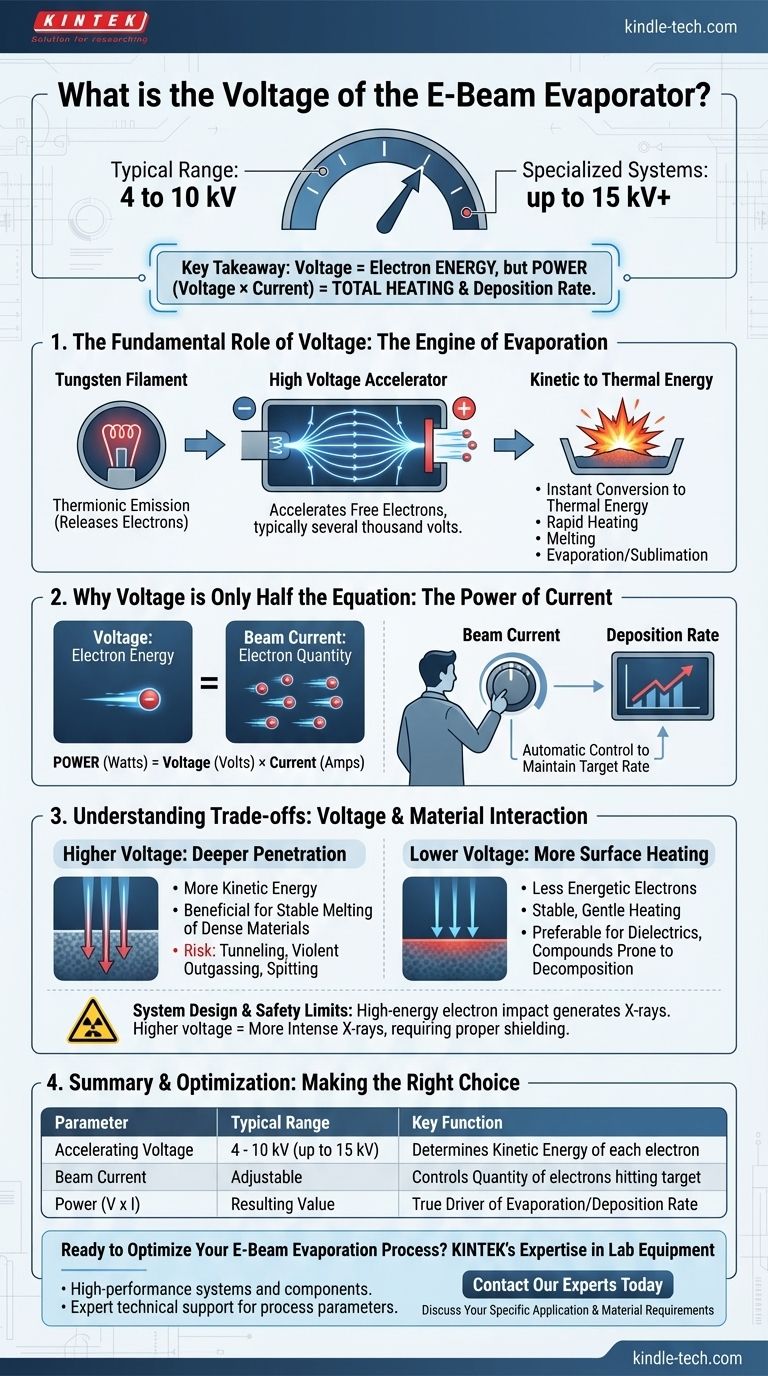

In an electron beam evaporator, the accelerating voltage is not a single fixed value but typically operates within a range of 4 to 10 kilovolts (kV). Some specialized systems may use voltages as high as 15 kV or more. The specific voltage is determined by the system's design, the power supply's capabilities, and the material being evaporated.

The key takeaway is that voltage determines the energy of each electron, but it is the total power—the product of voltage and beam current—that ultimately controls the heating of the source material and, therefore, the deposition rate.

The Fundamental Role of Voltage in E-Beam Evaporation

To understand the system, we must first understand the purpose of high voltage. It is the engine that drives the entire evaporation process by creating a high-energy electron beam.

Generating the Electron Beam

An e-beam gun starts with a tungsten filament. When a current is passed through this filament, it heats up and releases a cloud of electrons through a process called thermionic emission.

The High Voltage Accelerator

This is where the main voltage comes into play. A strong electric field is established between the negatively charged filament and the positively charged anode/crucible (hearth). This high-voltage potential, typically several thousand volts, forcefully accelerates the free electrons, pulling them away from the filament and directing them toward the source material.

From Kinetic Energy to Thermal Energy

The accelerated electrons, now traveling at high velocity, are focused by magnetic fields onto a small spot on the source material in the crucible. Upon impact, their immense kinetic energy is instantly converted into thermal energy, causing the localized spot on the material to heat rapidly, melt, and then sublimate or evaporate.

Why Voltage is Only Half the Equation

Focusing solely on voltage provides an incomplete picture. For process control, another parameter is just as critical: beam current.

Introducing Beam Current

While voltage sets the energy of each individual electron, the beam current (or emission current) determines the quantity of electrons hitting the target per second. It is directly controlled by the temperature of the filament.

Power: The Real Driver of Deposition Rate

The actual heating effect is determined by the total power delivered to the source, calculated as:

Power (Watts) = Voltage (Volts) × Current (Amps)

This relationship is why operators primarily adjust the beam current to control the deposition rate. Since the voltage is often a fixed setting on many systems, increasing the current delivers more electrons, increases the total power, and evaporates more material.

The Practical Impact on Your Process

In a typical deposition process, an operator sets a target deposition rate (e.g., 1 Å/second). A feedback controller then automatically adjusts the emission current to maintain this rate, while the high voltage remains constant.

Understanding the Trade-offs and Constraints

The choice of operating voltage is not arbitrary; it involves important trade-offs related to material interaction and system safety.

Higher Voltage: Deeper Penetration

A higher accelerating voltage gives each electron more kinetic energy. This can lead to deeper energy penetration into the source material. For some dense materials, this is beneficial for stable melting. However, for others, it can cause "tunneling" or violent outgassing, leading to uncontrolled spitting of material.

Lower Voltage: More Surface Heating

Lower voltages result in less energetic electrons that deposit their energy closer to the surface of the material. This can provide a more stable and gentle heating effect, which is often preferable for dielectric materials or compounds that are prone to decomposition or spitting.

System Design and Safety Limits

The maximum voltage is fundamentally limited by the system's hardware, including the high-voltage power supply and the ceramic insulators that prevent arcing. Critically, the impact of high-energy electrons generates X-rays. Higher voltages produce more energetic and intense X-rays, demanding appropriate shielding and safety protocols.

Making the Right Choice for Your Goal

Understanding voltage helps you move from being a machine operator to a process expert. Use these principles to guide your thinking.

- If your primary focus is basic understanding: Remember that voltage accelerates electrons to create heat, but power (voltage x current) governs the evaporation rate.

- If your primary focus is process optimization: Pay attention to how your material responds. If you experience spitting, a lower voltage (if adjustable) might provide a more stable melt pool.

- If your primary focus is system troubleshooting: Unstable deposition rates are more often linked to the beam current control loop, power supply stability, or beam sweep programming than to a fluctuating high voltage.

Ultimately, mastering e-beam evaporation is about understanding the interplay between voltage, current, and the specific properties of your material.

Summary Table:

| Parameter | Typical Range | Key Function |

|---|---|---|

| Accelerating Voltage | 4 - 10 kV (up to 15 kV) | Determines the kinetic energy of each electron |

| Beam Current | Adjustable | Controls the quantity of electrons hitting the target |

| Power (V x I) | Resulting value | The true driver of the evaporation/deposition rate |

Ready to Optimize Your E-Beam Evaporation Process?

Understanding the interplay of voltage and current is key to achieving precise, high-quality thin-film deposition. Whether you are developing new materials or troubleshooting an existing process, KINTEK's expertise in lab equipment can help.

We provide:

- High-performance e-beam evaporation systems and components.

- Expert technical support to help you master process parameters.

Let's discuss your specific application and material requirements. Contact our experts today to enhance your lab's capabilities with KINTEK solutions.

Visual Guide

Related Products

- Electron Beam Evaporation Coating Conductive Boron Nitride Crucible BN Crucible

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Electric Heated Hydraulic Vacuum Heat Press for Lab

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

People Also Ask

- What are the strengths of brazing? Achieve Strong, Clean, and Precise Metal Joining

- What materials are used in electron beam evaporation? Master High-Purity Thin Film Deposition

- How source material is evaporated during deposition? A Guide to Resistive vs. E-Beam Methods

- What are two common ways to heat the source material in evaporation? Resistive vs. E-Beam Methods

- What is the difference between thermal and electron beam evaporation? Unlock the Right Thin Film Deposition Method