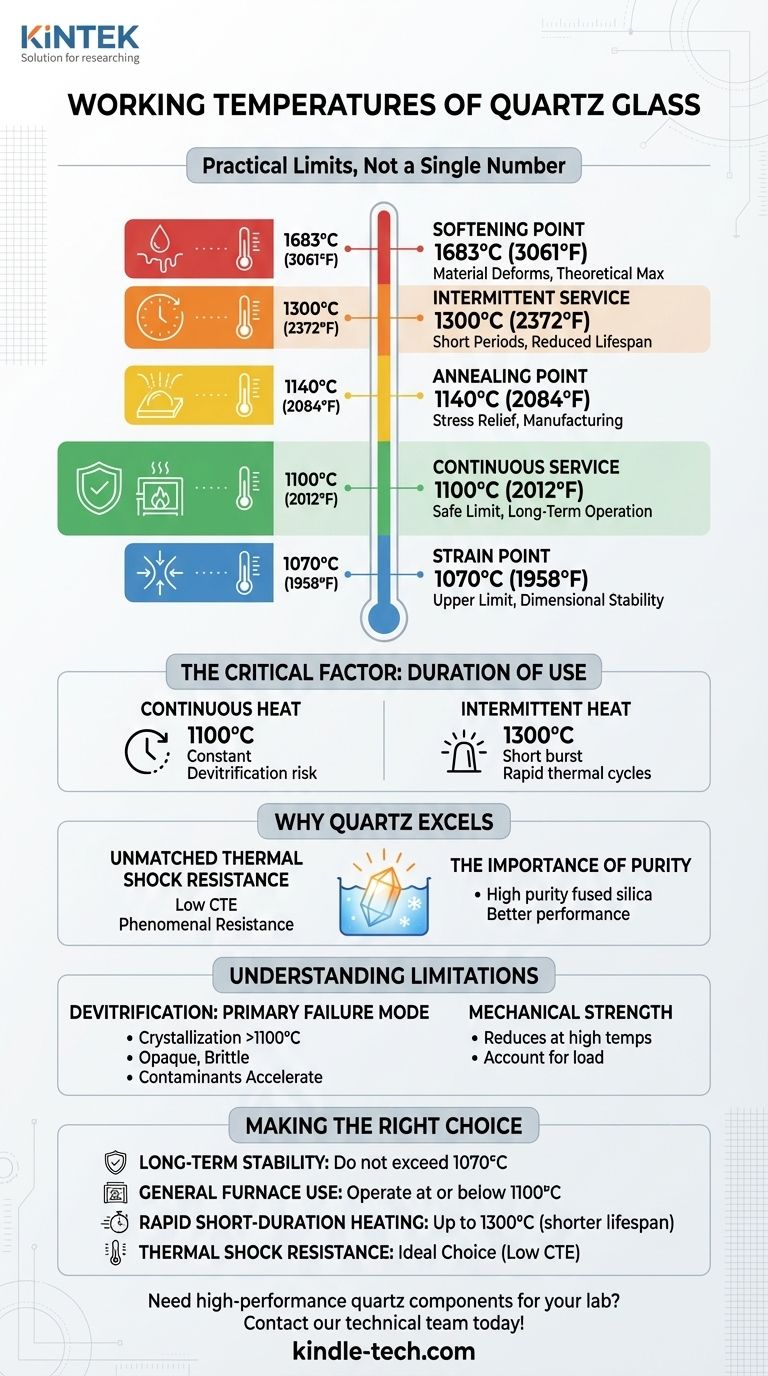

In practice, quartz glass is a high-performance material that has different operational temperature limits depending on the duration of use. Its long-term, continuous service temperature is typically around 1100°C (2012°F), while it can withstand intermittent temperatures up to 1300°C (2372°F) for short periods. The material begins to soften significantly around 1683°C (3061°F).

Understanding the "working temperature" of quartz is not about a single number. It requires distinguishing between the practical limit for continuous, long-term operation and the absolute maximum temperatures the material can endure before it begins to fail.

Deconstructing Quartz's Thermal Properties

To use quartz glass effectively and safely, you must understand its key temperature thresholds. These points define how the material behaves under thermal stress.

The Softening Point

The softening point is the temperature at which the material begins to deform under its own weight. For quartz glass, this is approximately 1683°C (3061°F). This is a theoretical maximum and not a practical working temperature, as the material loses its structural integrity here.

The Annealing Point

The annealing point, around 1140°C (2084°F), is a critical temperature for manufacturing. At this point, internal stresses within the glass can be relieved in a matter of minutes. For an end-user, it signifies a range where the material is becoming significantly less viscous.

The Strain Point

The strain point, approximately 1070°C (1958°F), represents the upper ceiling for long-term service. Above this temperature, internal stresses can develop, and the material will begin to deform over time. This is often considered the most conservative limit for any application requiring high dimensional stability.

The Critical Factor: Duration of Use

The most common point of failure in high-temperature applications comes from misunderstanding the difference between short-term and continuous heat exposure.

Continuous Service Temperature

For applications requiring constant, uninterrupted high heat, the safe limit for quartz glass is generally considered 1100°C (2012°F). Operating continuously above this temperature, especially in the presence of contaminants, risks a process called devitrification.

Intermittent Service Temperature

Quartz can be pushed to higher temperatures, up to 1300°C (2372°F), for very brief periods. This is common in applications like semiconductor processing where rapid thermal cycles occur. However, repeated exposure to these temperatures will significantly shorten the material's lifespan.

Why Quartz Excels at High Temperatures

Quartz's unique properties are what make it suitable for extreme thermal environments where other materials would fail catastrophically.

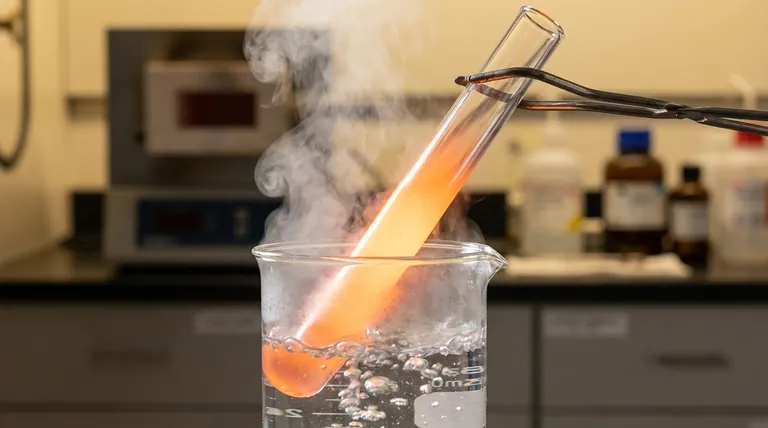

Unmatched Thermal Shock Resistance

The defining characteristic of quartz glass is its extremely low coefficient of thermal expansion (CTE). This means it expands and contracts very little when its temperature changes.

This property gives it phenomenal resistance to thermal shock. You can take a piece of quartz heated to over 1000°C and plunge it into cold water without it cracking. This is impossible for standard glass or ceramics.

The Importance of Purity

High-purity fused silica (synthetic quartz) generally has better high-temperature performance than less pure fused quartz. The presence of impurities, especially alkalis like sodium or potassium, can act as a flux, lowering the viscosity and reducing the effective working temperature.

Understanding the Trade-offs and Limitations

While quartz is a remarkable material, it has clear boundaries and failure modes that must be respected in any design.

Devitrification: The Primary Failure Mode

The primary enemy of quartz at high temperatures is devitrification. This is a process where the amorphous, glassy structure of quartz slowly crystallizes into a form called cristobalite.

This process begins to accelerate above 1100°C and causes the material to become opaque, brittle, and mechanically weak, eventually leading to failure. Surface contaminants like dust, fingerprints (salts), and oils can dramatically speed up devitrification.

Mechanical Strength at Temperature

Like all materials, quartz glass becomes softer and weaker as it approaches its softening point. While it maintains excellent strength at room temperature, its ability to bear a mechanical load is significantly reduced at its upper working temperatures. This must be accounted for in any structural application.

Making the Right Choice for Your Application

Selecting the correct operating parameters is essential for safety, reliability, and cost-effectiveness.

- If your primary focus is maximum long-term stability: Do not exceed a continuous operating temperature of 1070°C (1958°F), the strain point.

- If your primary focus is general continuous furnace use: Operate at or below 1100°C (2012°F) and ensure components are kept meticulously clean to prevent devitrification.

- If your primary focus is rapid, short-duration heating: You can use the material intermittently up to 1300°C (2372°F), but plan for a shorter component lifespan.

- If your primary focus is thermal shock resistance: Quartz is your ideal choice, as its low CTE provides reliability across extreme temperature gradients that other materials cannot handle.

By respecting these thermal limits, you can fully leverage the exceptional performance of quartz glass in your most demanding applications.

Summary Table:

| Temperature Threshold | Value (°C) | Value (°F) | Key Significance |

|---|---|---|---|

| Softening Point | 1683°C | 3061°F | Material deforms under its own weight; theoretical maximum |

| Annealing Point | 1140°C | 2084°F | Internal stresses can be relieved quickly |

| Strain Point | 1070°C | 1958°F | Upper limit for long-term dimensional stability |

| Continuous Service | 1100°C | 2012°F | Safe limit for long-term, uninterrupted operation |

| Intermittent Service | 1300°C | 2372°F | Maximum for short-duration use; reduces lifespan |

Need high-performance quartz components for your lab?

Understanding the precise thermal limits of quartz glass is critical for the safety and success of your high-temperature processes. At KINTEK, we specialize in supplying high-purity quartz lab equipment that delivers unmatched thermal shock resistance and durability for applications like semiconductor processing, heat treatment, and material synthesis.

Our experts can help you select the right quartzware for your specific temperature requirements, ensuring optimal performance and longevity.

Contact our technical team today to discuss your application and get a personalized solution!

Visual Guide

Related Products

- High Temperature Resistant Optical Quartz Glass Sheet

- Optical Window Glass Substrate Wafer Single Double Sided Coated K9 Quartz Sheet

- 400-700nm Wavelength Anti Reflective AR Coating Glass

- Optical Ultra-Clear Glass Sheet for Laboratory K9 B270 BK7

- Zinc Selenide ZnSe Optical Window Glass Substrate Wafer and Lens

People Also Ask

- How do you bend a quartz tube? Master the High-Temperature Process for Precision Results

- Why are zirconia ball mill jars required for zirconium halide electrolytes? Ensure Pure, High-Conductivity Synthesis

- Why are zirconia grinding balls used for milling c-LLZO? Ensure High Purity for Solid-State Battery Materials

- What is the primary purpose of using alumina sintering plates? Ensure Purity for R1/3Zr2(PO4)3 Samples

- How does the performance of a throttle valve affect the quality of Tantalum Carbide coatings? Optimize Coating Density

- Why are high-precision temperature controllers and K-type thermocouples essential for Metformin oxidative cleavage?

- How should one select a rotary vane vacuum pump based on the intended application? Expert Guide to Optimal Selection

- What is the operating temperature of a quartz tube? Maximize Tube Life & Process Efficiency