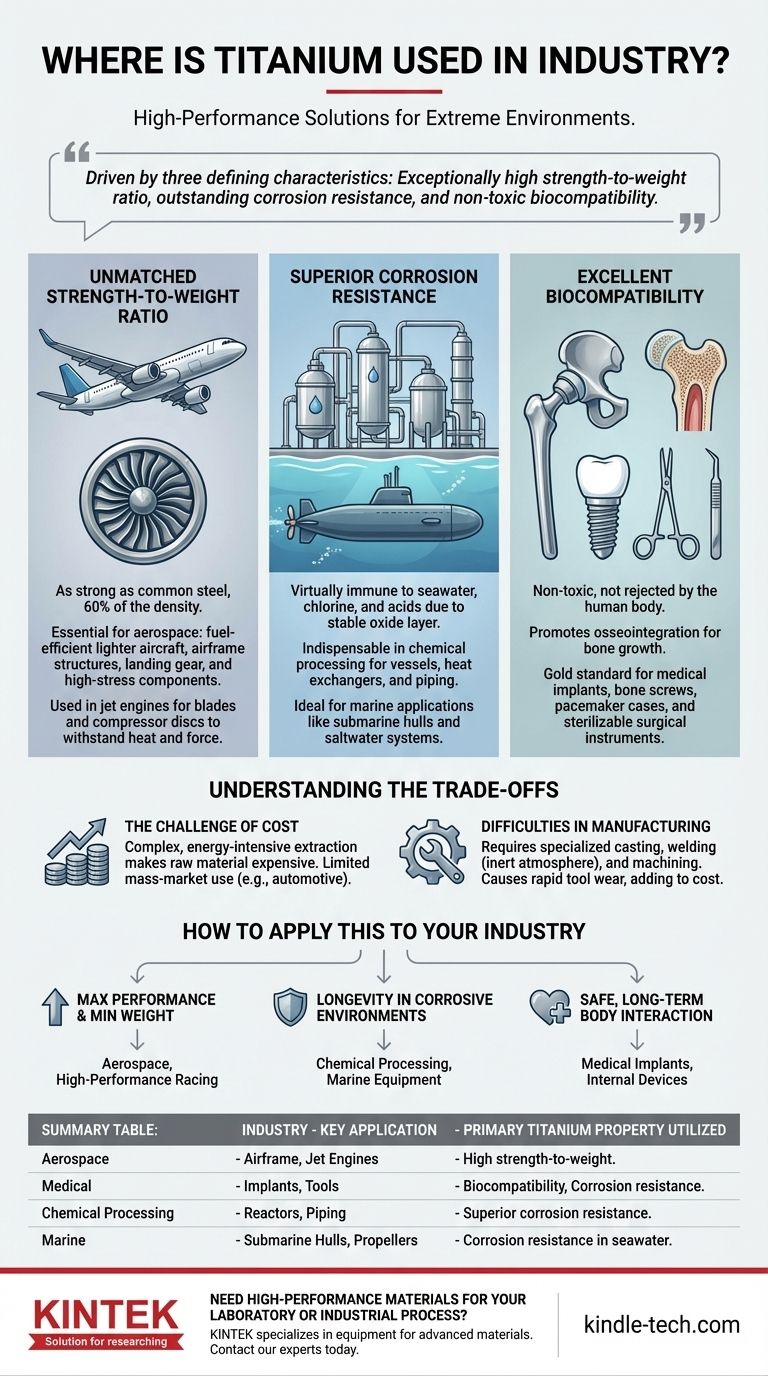

Titanium is used in industries where performance is non-negotiable. Its primary applications are found in the aerospace, medical, chemical processing, and marine sectors, where its unique combination of properties justifies its high cost.

The decision to use titanium is almost always driven by its three defining characteristics: an exceptionally high strength-to-weight ratio, outstanding corrosion resistance, and its non-toxic, biocompatible nature.

The Core Properties Driving Titanium's Use

Titanium is rarely chosen for mundane applications. It is an engineered solution for extreme environments where other metals would fail or impose a significant weight penalty.

Unmatched Strength-to-Weight Ratio

Titanium alloys are as strong as many common steels but at only 60% of the density. This is the single most important property for the aerospace industry.

Lighter aircraft are more fuel-efficient and can carry heavier payloads. This makes titanium the material of choice for critical airframe structures, landing gear, and high-stress fasteners.

Jet engines also rely heavily on titanium for components like fan blades and compressor discs, which must withstand immense rotational forces and high temperatures without adding unnecessary weight.

Superior Corrosion Resistance

Titanium naturally forms a stable, protective oxide layer that makes it virtually immune to corrosion from seawater, chlorine, and a wide range of industrial acids.

This makes it indispensable in chemical processing plants for vessels, heat exchangers, and piping systems that handle aggressive chemicals.

In marine applications, titanium is used for submarine hulls, propeller shafts, and saltwater cooling systems where steel would quickly degrade.

Excellent Biocompatibility

Titanium is non-toxic and is not rejected by the human body. Its surface allows bone to grow and adhere to it, a process known as osseointegration.

This makes it the gold standard for medical implants, including hip and knee replacements, dental implants, bone screws, and pacemaker cases.

It is also used for surgical instruments because it is strong, lightweight, corrosion-resistant, and can be repeatedly sterilized.

Understanding the Trade-offs

While titanium's performance is exceptional, it is not a universally applicable material. Its adoption is limited by significant practical and economic factors.

The Challenge of Cost

Titanium is expensive. The process of extracting the metal from its ore is complex and energy-intensive, making the raw material significantly more costly than steel or aluminum.

This high initial cost is the primary barrier to its use in mass-market applications like automotive manufacturing or general construction.

Difficulties in Manufacturing

Working with titanium is notoriously difficult. It requires specialized techniques for casting, welding, and machining, which adds considerably to the final component cost.

Its reactivity at high temperatures means it must be welded in an inert atmosphere, and its toughness causes rapid wear on machine tools. These challenges require specialized equipment and expertise.

How to Apply This to Your Industry

Choosing titanium is a matter of weighing its unparalleled performance against its high cost. The decision hinges on the primary requirement of the application.

- If your primary focus is maximum performance and minimal weight: Titanium is the premier choice for aerospace and high-performance racing components where every gram matters.

- If your primary focus is longevity in a corrosive environment: Titanium offers a "fit and forget" solution for chemical processing and marine equipment, justifying its cost through reduced maintenance and replacement.

- If your primary focus is safe, long-term interaction with the human body: The biocompatibility of titanium makes it the undisputed material for medical implants and internal devices.

Ultimately, titanium is specified when failure is not an option and the operational demands exceed the capabilities of conventional metals.

Summary Table:

| Industry | Key Application | Primary Titanium Property Utilized |

|---|---|---|

| Aerospace | Airframe structures, jet engine components | High strength-to-weight ratio |

| Medical | Implants (hips, knees, dental), surgical tools | Biocompatibility, corrosion resistance |

| Chemical Processing | Reactors, heat exchangers, piping | Superior corrosion resistance |

| Marine | Submarine hulls, propeller shafts, cooling systems | Corrosion resistance in seawater |

Need High-Performance Materials for Your Laboratory or Industrial Process?

Titanium's exceptional properties make it ideal for demanding applications, but working with it requires specialized knowledge and equipment. KINTEK specializes in providing high-quality lab equipment and consumables tailored to handle advanced materials like titanium.

Whether you are in R&D for aerospace components, developing medical implants, or processing corrosive chemicals, we can support your mission-critical work with reliable solutions.

Contact our experts today to discuss how KINTEK can enhance your research and production capabilities.

Visual Guide

Related Products

- Electric Split Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What features do modern ULT freezers include for monitoring and safety? Protect Your Critical Samples with Intelligent Design

- Does heat treatment improve corrosion resistance? A Guide to Optimizing Material Performance

- What is the pressure range for sputtering? Optimize Your Thin Film Deposition Process

- What is the process of gold sputtering? A Guide to High-Precision Thin Film Deposition

- What is bio-oil in biomass? A Guide to the Liquid Fuel from Pyrolysis

- What is the process of thin film coating? A Guide to Precision Layer Deposition

- What are the disadvantages of hardening? The Critical Trade-offs of Increased Brittleness and Stress

- What role does a constant temperature laboratory oven play in preparing waste eggshell catalysts? Ensure Peak Efficiency