The standard instrument used for sieving fine aggregates is a mechanical sieve shaker. This device automates the process of agitating a stack of nested test sieves, allowing for the efficient and repeatable separation of particles by size. A proper sieve analysis is fundamental to determining the gradation, or particle size distribution, of materials like sand, which is a critical quality control test in concrete, asphalt, and geotechnical engineering.

The specific model of sieve shaker is less important than its ability to provide consistent, repeatable energy to the sieve stack. Your true goal is to achieve an accurate gradation analysis that complies with industry standards, such as ASTM C136, and the entire testing procedure—from sample preparation to the final calculation—is what guarantees that result.

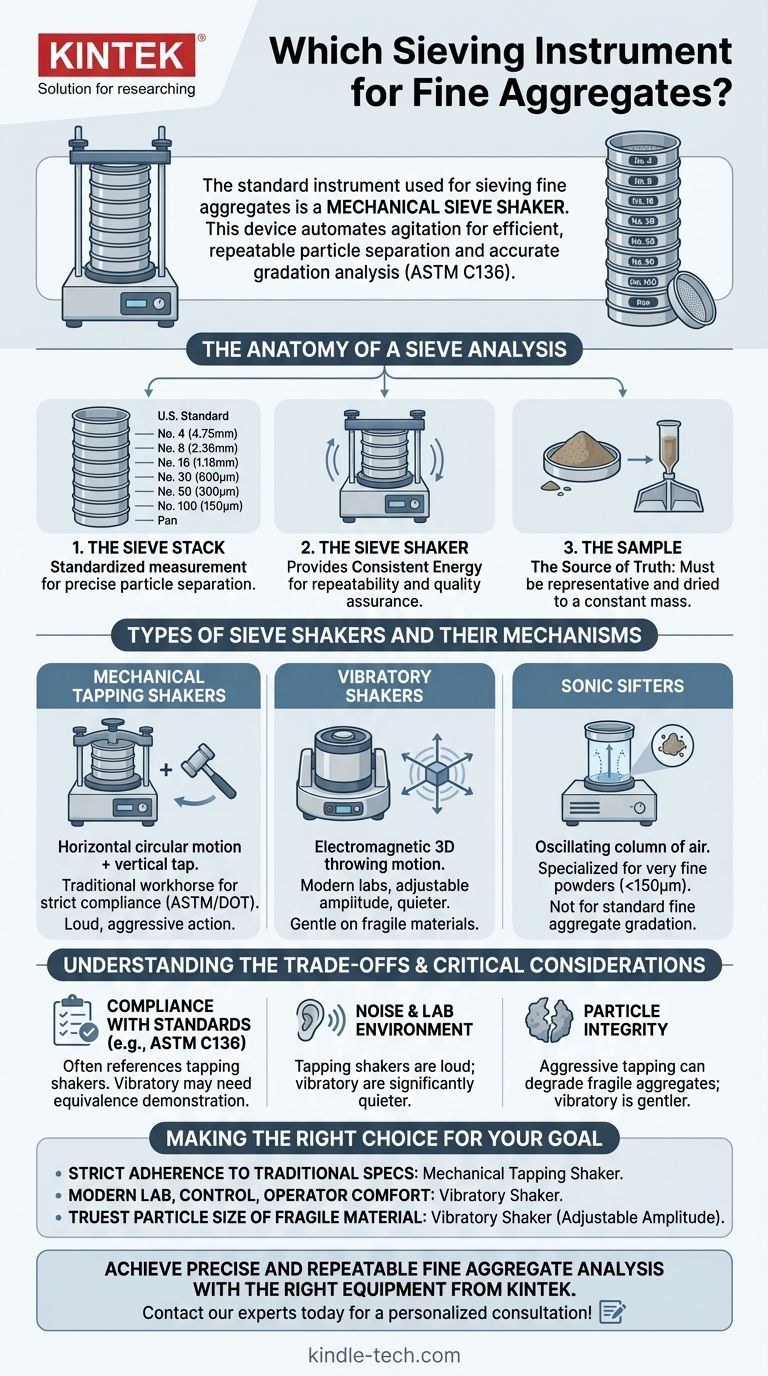

The Anatomy of a Sieve Analysis

A sieve shaker is just one component of a controlled testing process. Understanding the full system is key to obtaining reliable data on your fine aggregates.

The Sieve Stack: Standardized Measurement

The core of the analysis is a stack of test sieves. These are circular frames holding a wire mesh screen with precisely specified square openings.

For fine aggregates (sand), a typical stack, from top to bottom, includes U.S. Standard sieve sizes No. 4 (4.75mm), No. 8 (2.36mm), No. 16 (1.18mm), No. 30 (600µm), No. 50 (300µm), and No. 100 (150µm). A solid pan sits at the very bottom to collect all material that passes through the No. 100 sieve.

The Sieve Shaker: Providing Consistent Energy

The shaker's purpose is to eliminate the variability of manual shaking. It imparts a standardized mechanical action that ensures particles are given ample opportunity to pass through the mesh openings until they are retained on the correct sieve.

This consistent energy is what makes the test repeatable between different technicians and different labs, which is crucial for quality assurance.

The Sample: The Source of Truth

The most advanced shaker cannot fix a poor sample. The fine aggregate tested must be a representative subsample of the larger stockpile, typically obtained by quartering or using a sample splitter.

Furthermore, the sample must be dried to a constant mass before sieving. This removes moisture content as a variable, ensuring you are only measuring the weight of the aggregate particles themselves.

Types of Sieve Shakers and Their Mechanisms

While serving the same function, different shakers use distinct mechanical actions. The method used can be specified by the testing standard you must follow.

Mechanical Tapping Shakers

These are the traditional workhorses of the industry, often referred to by the common brand name "Ro-Tap." They combine a horizontal, circular motion with a vertical tapping action from a hammer arm on top of the sieve stack.

This aggressive action is very effective at separating particles and is explicitly referenced in many older ASTM and AASHTO standards, making it a common choice for compliance testing.

Vibratory Shakers

These more modern units use an electromagnetic drive to create a three-dimensional throwing motion that moves the sample up and across the sieve surface.

They are significantly quieter than tapping shakers and often allow for adjustable amplitude and sieving intervals. This provides more control and is gentler on friable aggregates that might otherwise break down during a vigorous tapping test.

Sonic Sifters

This specialized category is primarily used for very fine powders and materials below 150µm (passing the No. 100 sieve), not for a standard fine aggregate gradation. It uses an oscillating column of air, not mechanical agitation, to separate particles.

Understanding the Trade-offs and Critical Considerations

Choosing an instrument involves balancing compliance, lab environment, and material type.

Compliance with Standards

This is the most critical factor. Many construction material specifications and government contracts reference standards like ASTM C136, which were often developed using mechanical tapping shakers. While vibratory shakers are accepted, using one may require you to demonstrate that it produces statistically equivalent results.

Noise and Lab Environment

Mechanical tappers are extremely loud and require a dedicated sound-dampening enclosure for safe and comfortable lab operation. Vibratory shakers are a fraction as loud and are far better suited for an open lab environment.

Particle Integrity

The aggressive motion of a tapping shaker can degrade softer or more brittle aggregates, breaking larger particles down and skewing the gradation results to appear finer than they actually are. A vibratory shaker's gentler action minimizes this risk.

Making the Right Choice for Your Goal

Select your equipment based on your primary testing requirement.

- If your primary focus is strict adherence to traditional DOT or ASTM specifications for contractual work: A mechanical tapping shaker is the most defensible and widely recognized choice.

- If your primary focus is internal quality control in a modern lab environment: A vibratory shaker offers superior operator comfort, more control, and is better for a wider range of material types.

- If your primary focus is the truest possible particle size of a fragile material: A vibratory shaker with adjustable amplitude allows you to tune the energy to avoid particle degradation.

Ultimately, the best instrument is one that provides repeatable results that comply with your project's specific testing requirements.

Summary Table:

| Sieve Shaker Type | Key Mechanism | Best For | Key Considerations |

|---|---|---|---|

| Mechanical Tapping (e.g., Ro-Tap) | Horizontal circular motion + vertical tap | Strict compliance with traditional ASTM/DOT specs | Loud, can degrade fragile particles |

| Vibratory | Electromagnetic 3D throwing motion | Modern labs, fragile materials, operator comfort | Quieter, adjustable amplitude |

| Sonic Sifter | Oscillating air column | Very fine powders (<150µm) | Not for standard fine aggregate gradation |

Achieve precise and repeatable fine aggregate analysis with the right equipment from KINTEK.

Whether your lab requires strict ASTM C136 compliance with a mechanical shaker or seeks the quieter, gentler operation of a vibratory model, KINTEK has the solution. We specialize in high-quality lab equipment, including sieve shakers and test sieves, to ensure your gradation tests are accurate, efficient, and meet industry standards.

Let us help you select the ideal instrument for your specific needs. Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

- Three-dimensional electromagnetic sieving instrument

- Laboratory Multifunctional Small Speed-Adjustable Horizontal Mechanical Shaker for Lab

People Also Ask

- What is the critical function of high-precision sieving for aluminum powders? Ensure Uniform Composite Integrity

- What is the role of crushing and sieving systems in wheat straw pretreatment? Maximize Sugar Yield through Particle Sizing

- How does a laboratory shaker or extractor function during 133Ba adsorption? Optimize Your Kinetic Evaluation

- What machine is used for sieving? A Guide to Choosing the Right Sieve Shaker

- What is the procedure of sieve shaker? A Step-by-Step Guide to Accurate Particle Size Analysis

- Why is precise speed control necessary for a mechanical shaker or stirrer during microalgae anaerobic digestion?

- What is the frequency of a vibrating screen? Unlock Optimal Material Separation Efficiency

- Which types of diameter or size can be determined using sieve shaker method for the given granular sample? A Guide to the 38 µm to 4 mm Range