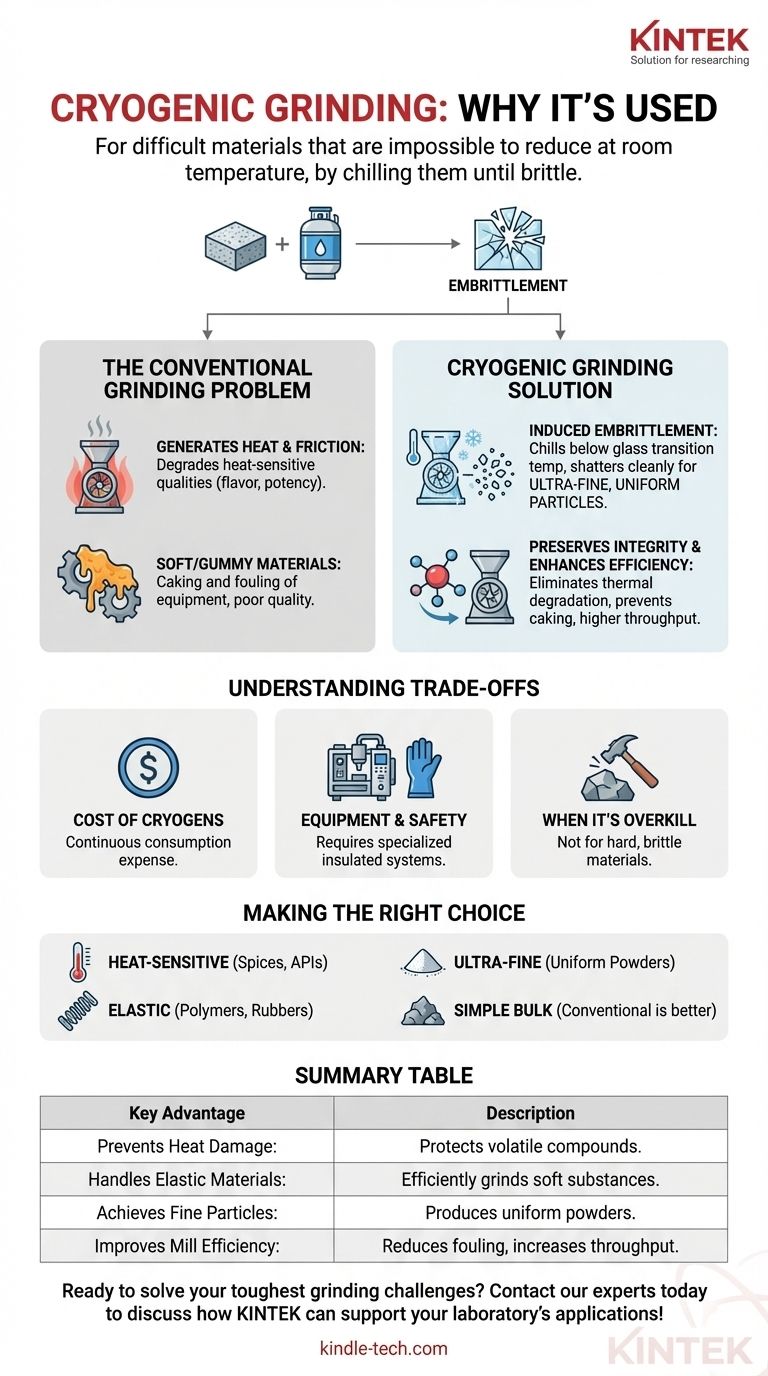

At its core, cryogenic grinding is used for materials that are difficult or impossible to reduce in size at room temperature. By using a cryogen like liquid nitrogen, the process chills a material until it becomes extremely brittle. This embrittlement allows for efficient shattering into fine, uniform particles, preventing issues like melting, stickiness, or the degradation of heat-sensitive components.

The primary purpose of cryogenic grinding is not simply to make a material cold, but to temporarily change its physical properties from ductile and tough to hard and brittle. This transformation overcomes the common failures of conventional grinding, such as heat damage, tool fouling, and inconsistent particle size.

The Fundamental Problem with Conventional Grinding

Standard grinding methods rely on mechanical force—impact, shear, or compression—to break down materials. While effective for many substances, this process generates significant friction and heat.

Heat Generation and Its Consequences

The intense energy of grinding is largely converted into heat. For heat-sensitive materials like spices, pharmaceuticals, or certain polymers, this can degrade or destroy the very qualities you wish to preserve, such as flavor, aroma, or chemical potency.

The Challenge of Soft or Gummy Materials

Many materials, particularly plastics, elastomers, and waxes, do not grind well at ambient temperatures. Instead of shattering, they become soft, sticky, or elastic under the stress of the mill. This leads to caking and fouling of the equipment, reduced throughput, and poor particle quality.

How Cryogenic Grinding Solves the Problem

Cryogenic grinding directly addresses the limitations of heat and ductility by introducing extreme cold into the process, fundamentally changing how the material behaves.

The Principle of Embrittlement

Cooling a material below its glass transition temperature makes it lose its ductile properties and become brittle and glass-like. When the grinding force is applied, the embrittled material shatters cleanly and instantly. This is the key to achieving ultra-fine and highly uniform particles.

Preserving Product Integrity

Because the entire system is flooded with an inert cryogen like liquid nitrogen, heat is immediately absorbed. This eliminates thermal degradation, protecting the quality of heat-labile components. It also prevents oxidation by displacing oxygen, further preserving the final product's integrity.

Enhancing Mill Efficiency

By preventing materials from becoming sticky, cryogenic grinding eliminates product caking inside the mill. This results in significantly higher production rates, lower energy consumption per unit of product, and reduced wear on grinding components. The process is faster and requires less downtime for cleaning.

Understanding the Trade-offs and Considerations

While powerful, cryogenic grinding is a specialized process with specific requirements. It is not a universal solution for all grinding tasks.

The Cost of Cryogens

The primary operational cost is the continuous consumption of liquid nitrogen or another cryogen. This expense must be justified by the added value, such as improved product quality or the ability to process an otherwise impossible material.

Equipment and Safety Complexity

Cryogenic systems require insulated machinery, specialized handling equipment, and strict safety protocols for managing extremely cold substances. The initial capital investment and operational complexity are higher than for conventional grinding setups.

When It Is Overkill

For hard, brittle materials that grind easily at room temperature (e.g., minerals, salts, or ceramics), cryogenic grinding offers no significant advantage and would only add unnecessary cost and complexity.

Making the Right Choice for Your Application

Selecting the right grinding method depends entirely on your material's properties and your final product goals.

- If your primary focus is preserving heat-sensitive qualities: Cryogenic grinding is essential for protecting volatile compounds in spices, foods, and active pharmaceutical ingredients (APIs).

- If your primary focus is processing soft or elastic materials: Cryogenic grinding is the superior method for polymers, rubbers, waxes, and adhesives that would otherwise melt or foul equipment.

- If your primary focus is achieving ultra-fine, uniform powders: The embrittlement process allows for a level of particle size control and consistency that is often unattainable with conventional methods.

- If your primary focus is cost-effective bulk reduction of simple materials: Conventional grinding remains the most economical and straightforward choice for materials that are not heat-sensitive or ductile.

By fundamentally altering a material's physical state for the purpose of size reduction, cryogenic grinding unlocks processing capabilities that are otherwise unattainable.

Summary Table:

| Key Advantage | Description |

|---|---|

| Prevents Heat Damage | Protects volatile compounds in spices, pharmaceuticals, and polymers. |

| Handles Elastic Materials | Efficiently grinds soft, sticky substances like plastics and rubbers. |

| Achieves Fine Particles | Produces ultra-fine, uniform powders through material embrittlement. |

| Improves Mill Efficiency | Reduces equipment fouling, increases throughput, and lowers energy use. |

Ready to solve your toughest grinding challenges? If you work with heat-sensitive spices, pharmaceuticals, polymers, or other difficult-to-grind materials, KINTEK's cryogenic grinding solutions can preserve your product's quality and enhance your process efficiency. Our expertise in lab equipment ensures you get the right system for your needs. Contact our experts today to discuss how we can support your laboratory's grinding applications!

Visual Guide

Related Products

- Liquid Nitrogen Cryogenic Grinder Mill Cryomill with Screw Feeder

- lab cryogenic grinding use liquid-nitrogen for pulverizing plastic raw materials and heat sensitive materials

- Low-Temperature Water-Cooled Touchscreen Vibratory Ultrafine Pulverizer

- Laboratory Jar Ball Mill with Alumina Zirconia Grinding Jar and Balls

- Laboratory Hybrid Tissue Grinding Mill

People Also Ask

- What is the cryogenic grinding process? Achieve Superior Quality and Efficiency for Sensitive Materials

- Which tool could be used to pulverize an object? Match the Tool to Your Material's Hardness and Brittleness

- How do crushing and grinding systems improve microalgae gas production? Optimize Biomass Pretreatment for Higher Yields

- What is the purpose of a pulverizer? Unlock Material Potential with Fine Grinding

- What food is cryogenic grinding? The Ultimate Guide to Preserving Flavor & Aroma