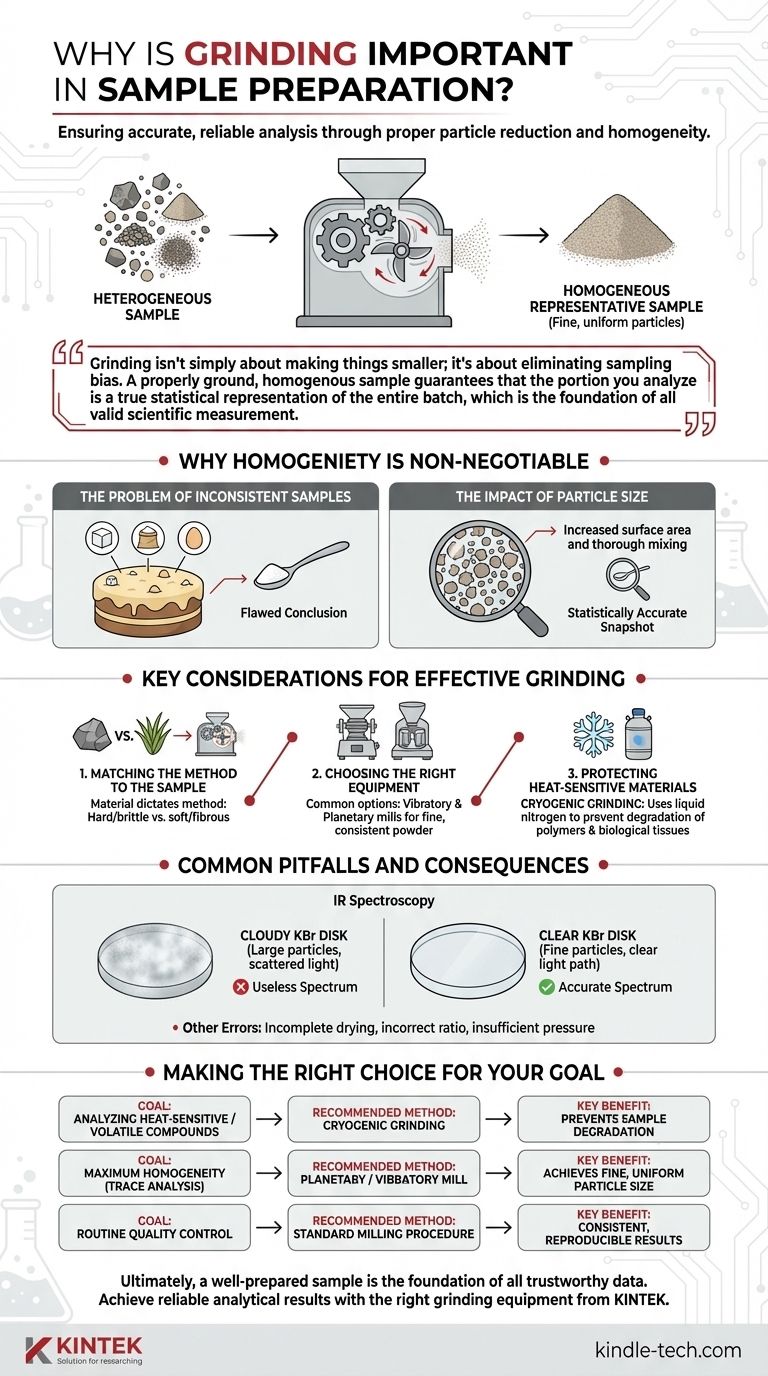

In sample preparation, grinding is the critical step that ensures your analysis is both accurate and reliable. This process reduces the size of sample particles to create a homogenous mixture, which is essential for obtaining high-quality data. Without proper grinding, the small portion of the material you analyze may not be a true representation of the entire batch, leading to flawed conclusions.

Grinding isn't simply about making things smaller; it's about eliminating sampling bias. A properly ground, homogenous sample guarantees that the portion you analyze is a true statistical representation of the entire batch, which is the foundation of all valid scientific measurement.

Why Homogeneity is Non-Negotiable

The primary goal of grinding is to prepare a "representative sample." This means any fraction of the ground material has the exact same composition as the whole.

The Problem of Inconsistent Samples

Imagine trying to determine the sugar content of a cake batter by testing a single spoonful. If the ingredients are not perfectly mixed, one spoonful might contain a lump of sugar while another contains none.

Grinding and mixing prevent this. By reducing all components to a fine, uniform powder, you ensure that every scoop, no matter how small, reflects the overall composition.

The Impact of Particle Size

Reducing particle size dramatically increases the surface area of the sample and allows for more thorough mixing.

This ensures that when you take a small subsample for analysis—whether for spectroscopy, chromatography, or elemental analysis—you are getting a statistically accurate snapshot of the entire batch.

Key Considerations for Effective Grinding

The correct grinding strategy depends entirely on your sample's properties and your analytical goals. There is no one-size-fits-all approach.

Matching the Method to the Sample

The type of material dictates the method. Hard, brittle materials may require a high-impact planetary mill, while softer, more fibrous materials may need a different approach.

Choosing the Right Equipment

The two most common types of laboratory mills are vibratory mills and planetary mills. These are designed to grind samples to a fine, consistent powder suitable for a wide range of analytical techniques.

Protecting Heat-Sensitive Materials

For materials that can be damaged by heat, such as polymers or biological tissues, cryogenic grinding is the ideal solution.

By cooling the sample with liquid nitrogen, this method makes it brittle and easy to grind while preserving heat-sensitive components. It also allows for very short grinding times and easy cleanup.

Common Pitfalls and Consequences

Improper grinding is not a minor inconvenience; it is a source of critical error that can invalidate your results.

The Spectroscopic Example: Cloudy KBr Disks

In infrared (IR) spectroscopy, a common technique involves mixing a sample with potassium bromide (KBr) and pressing it into a thin disk.

If the KBr mixture is not ground finely enough, the large particles will scatter the infrared light, resulting in a cloudy disk and a useless spectrum. This is a direct, physical manifestation of poor sample preparation.

Other Sources of Error

Other factors related to preparation can also ruin an analysis. These include using a sample that isn't fully dry, having a sample-to-KBr ratio that is too high, or not applying enough pressure when creating a pellet. Each of these highlights the need for a rigorous and consistent protocol.

Making the Right Choice for Your Goal

Your analytical objective should guide your preparation strategy. Before you begin, clarify your primary need.

- If your primary focus is analyzing heat-sensitive or volatile compounds: Cryogenic grinding is the only way to prevent sample degradation and ensure accurate results.

- If your primary focus is achieving maximum homogeneity for trace analysis: A high-energy method using a planetary or vibratory mill is required to reach the fine, uniform particle size needed for reproducibility.

- If your primary focus is routine quality control with stable materials: A standard milling procedure is often sufficient, but maintaining strict consistency in grinding time, equipment, and sample handling is paramount.

Ultimately, a well-prepared sample is the foundation of all trustworthy data.

Summary Table:

| Goal | Recommended Grinding Method | Key Benefit |

|---|---|---|

| Heat-sensitive/Volatile Compounds | Cryogenic Grinding | Prevents sample degradation |

| Maximum Homogeneity (Trace Analysis) | Planetary/Vibratory Mill | Achieves fine, uniform particle size |

| Routine Quality Control | Standard Milling | Consistent, reproducible results |

Achieve reliable analytical results with the right grinding equipment from KINTEK.

KINTEK specializes in laboratory mills and consumables designed for precise sample preparation. Whether your work requires cryogenic grinding for sensitive materials or high-energy milling for maximum homogeneity, our experts can help you select the ideal solution for your laboratory's needs.

Contact our team today to discuss your application and ensure your sample preparation is a solid foundation for accurate data.

Visual Guide

Related Products

- Laboratory Grinding Mill Mortar Grinder for Sample Preparation

- Laboratory Hybrid Tissue Grinding Mill

- Laboratory Disc Cup Vibratory Mill for Sample Grinding

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Laboratory Jar Ball Mill with Alumina Zirconia Grinding Jar and Balls

People Also Ask

- What is a mortar and pestle used for in a lab? A Guide to Precision Grinding and Mixing

- What is the primary purpose of using grinding tools like agate mortars? Optimize LTO Electrode Performance

- Why is an agate mortar and pestle preferred for grinding MAX phase? Ensure Sample Purity & Zero Contamination

- What is the function of using an agate mortar during the precursor mixing stage of sulfide solid electrolyte synthesis?

- What is the function of a mortar and pestle in ZnS nanoparticle prep? Optimize Your Sample Refinement