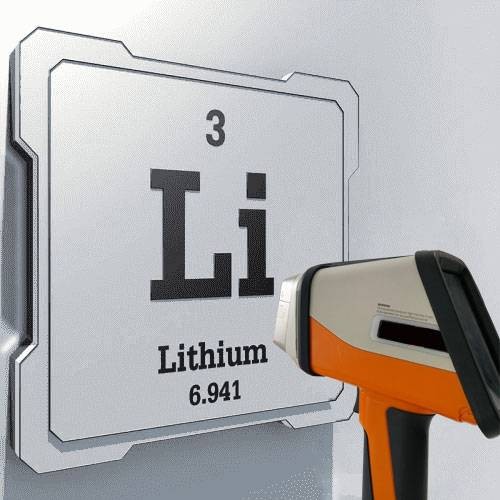

Introduction to Handheld Lithium Battery Analyzers

The comprehensive guide to handheld lithium battery analyzers provides an in-depth look at these advanced devices and their importance in various industries. From quality control and recycling to resource analysis and maintenance, these analyzers play a crucial role in the lithium battery market. The guide explores the capabilities of the XRF970 handheld lithium battery analyzer, its key components, and the various applications in the industry. It also provides guidelines for proper maintenance and daily use precautions to ensure the longevity and accuracy of these devices. Furthermore, the guide discusses the role of handheld analyzers in battery recycling, catalyst analysis, ternary lithium battery analysis, and the strategic importance in the global competition for lithium resources. Lastly, it speculates on future trends and innovations in handheld spectrometry technology and their implications for the lithium battery industry.

Key Applications of Handheld Analyzers in Lithium Battery Industry

Handheld analyzers play a crucial role in the lithium battery industry, particularly in quality control processes during battery manufacturing. These devices offer non-destructive testing and high-throughput capabilities, which are essential for ensuring the safety and efficiency of lithium batteries.

Quality Control of Battery Manufacturing: Handheld analyzers are extensively used to inspect and analyze key elements in battery raw materials and contact parts. These elements include iron, silver, cobalt, zinc, copper, nickel, and chromium, which are strictly limited in the electrodes to prevent battery failure, short circuits, or explosions. For instance, the concentration of Ni, Co, Mn elements in the precursor slurry powder is meticulously analyzed to maintain the quality and performance of the batteries.

Lithium Battery Production Equipment Inspection: Upstream battery equipment manufacturers utilize handheld analyzers to control and inspect the alloy material composition and coating thickness of key contact components. This meticulous inspection helps prevent accidents caused by the exposure of alloy materials or metal particles falling off into the lithium battery production process.

Waste Lithium Battery Recycling and Sorting: Handheld XRF analyzers are instrumental in the recycling and sorting of waste lithium batteries. These devices provide fast and accurate results with minimal sample preparation, enhancing the efficiency of the recycling process. The intuitive user interface and customizable software of these analyzers enable high-throughput testing, thereby increasing productivity.

Advantages of Handheld Lithium Ore Analyzers: In the competitive landscape of lithium resources, handheld spectrometers offer significant advantages. These devices can quickly analyze the lithium element composition and lithium ore grade at mining or trading sites, facilitating better decision-making in mining or trading activities. The benefits of these handheld spectrometers include fast analysis speed, higher analysis accuracy, lower detection limit, and a wide range of elements that can be analyzed. Additionally, their robust design ensures durability in harsh outdoor environments, making them ideal for on-site analysis.

Handheld Lithium Battery Analyzer: The XRF970 handheld lithium battery analyzer is a prime example of advanced technology in this field. It uses a ceramic packaged microfocus X-ray tube and a high-performance semiconductor detector, combined with advanced software algorithms, to quickly and accurately analyze regulated elements like Ni, Co, Mn in lithium batteries. This analyzer is essential for process quality control in lithium battery manufacturing and for sorting tasks in waste lithium battery recycling.

In conclusion, handheld analyzers are indispensable tools in the lithium battery industry, offering critical support in quality control, production equipment inspection, and waste battery recycling. Their ability to provide quick, accurate, and non-destructive analysis makes them a cornerstone of modern battery manufacturing and recycling processes.

Maintenance and Daily Use Precautions

Handheld XRF analyzers are versatile tools used across various industries for elemental analysis. Proper maintenance and daily use precautions are crucial for ensuring the longevity and accuracy of these devices. This section focuses on essential practices related to battery care, charging methods, and general upkeep.

Battery Care

Battery maintenance is a critical aspect of handheld XRF analyzer upkeep. Each device typically comes with two original batteries, which, when fully charged, can support continuous operation for about 5-6 hours. To maintain battery health and ensure reliable performance, it is important to follow the recommended charging procedures.

Charging Method

The batteries should be charged using the provided charger, which typically requires 4-6 hours for a full charge. It is advisable to charge the batteries in a controlled environment away from extreme temperatures to prevent damage. Overcharging should be avoided, as it can degrade battery performance and lifespan.

General Upkeep

General maintenance of handheld XRF analyzers involves regular checks and cleaning to prevent the accumulation of dust and debris, which can affect the accuracy of readings. The protective box, which shields the detector from contaminants, should be replaced regularly. This is particularly important after analyzing samples that may leave residues, such as aluminum alloys, which can affect subsequent measurements if not properly cleaned.

Calibration and Optimization

While not directly related to maintenance, proper calibration and optimization of the analyzer are essential for accurate results. The analyzer should be calibrated for specific analytical tasks and optimized for testing time based on the elements of interest. This ensures that the measurements are both accurate and efficient, reducing the risk of errors due to improper settings or outdated calibrations.

Safety Precautions

Safety is paramount when using handheld XRF analyzers, as they utilize X-rays which, although low in intensity, can be harmful with prolonged exposure. Operators should avoid direct contact with the sample during analysis and ensure that the beam is not directed towards people. Regular training on radiation safety is recommended to minimize health risks associated with X-ray exposure.

Conclusion

Proper maintenance and daily use precautions for handheld XRF analyzers are essential for maintaining the accuracy and reliability of these devices. By adhering to battery care guidelines, regular maintenance routines, and safety protocols, operators can ensure that their XRF analyzers provide consistent, high-quality results. This not only prolongs the lifespan of the equipment but also enhances the efficiency and safety of operations across various applications.

Analytical Capabilities in Battery Recycling and Catalyst Analysis

Portable X-ray fluorescence (XRF) analyzers play a crucial role in the recycling of waste lithium-ion batteries and the analysis of precious metals in automotive exhaust treatment devices. These handheld devices offer a non-destructive, quick, and accurate method to determine the elemental composition of materials, which is essential for efficient recycling processes and quality control in catalyst analysis.

Lithium-Ion Battery Recycling

In the recycling of lithium-ion batteries, portable XRF analyzers are instrumental in identifying the elemental content of batteries at various stages of the recycling process. These devices can detect metals such as lithium, cobalt, and nickel, which are critical components of lithium-ion batteries. During the disassembly and separation of materials, XRF analyzers help in sorting different types of batteries for appropriate recycling. This capability is vital as it ensures that valuable materials are recovered efficiently and safely, reducing the environmental impact and supporting a circular economy where materials are reused rather than discarded.

Catalyst Analysis in Automotive Exhaust Treatment Devices

Automotive exhaust catalytic converters contain precious metals like platinum, palladium, and rhodium, which are essential for catalyzing redox reactions that reduce harmful emissions. Handheld XRF analyzers are widely used in the analysis of these catalysts to assess the value of spent catalysts accurately. The XRF method can determine the content of these valuable metals with high precision, often up to tens of parts per million. This accuracy is crucial for ensuring fair trade in the recycling of catalytic converters, protecting the interests of both sellers and buyers.

Advantages of Handheld XRF Analyzers

The use of handheld XRF analyzers in both battery recycling and catalyst analysis offers several advantages. These devices are user-friendly, lightweight, and have a long operating time without the need for frequent recharging, making them ideal for on-site analysis. Additionally, XRF analyzers require minimal maintenance, which reduces operational costs and makes them a cost-effective investment with a quick return on investment.

In conclusion, the application of handheld XRF analyzers in battery recycling and catalyst analysis is pivotal for enhancing the efficiency and effectiveness of these processes. By providing rapid and accurate elemental analysis, these devices not only support the recovery of valuable materials but also contribute to environmental sustainability and economic viability in the recycling industry.

Role in Ternary Lithium Battery Analysis

In the realm of lithium battery technology, the composition of the cathode material plays a pivotal role in determining the performance and safety of the battery. Ternary lithium batteries, specifically, rely on a precise balance of nickel, cobalt, and manganese to optimize their energy density, stability, and lifespan. The XRF970 handheld lithium battery analyzer is a cutting-edge tool designed to facilitate this critical analysis, ensuring that the ratios of these elements are accurately determined.

The XRF970 utilizes a combination of advanced ceramic packaged microfocus X-ray tube technology and high-performance semiconductor detectors. This technology, coupled with sophisticated software algorithms, enables the device to quickly and accurately analyze the concentrations of nickel, cobalt, manganese, and other regulated elements within lithium batteries. The speed and precision of this analyzer are crucial for both manufacturers and recyclers, as they ensure that the batteries meet stringent quality and safety standards.

For battery manufacturers, the XRF970 serves as an indispensable tool for process quality control. By providing real-time analysis of the cathode material composition, manufacturers can make immediate adjustments to their production processes to maintain the desired ratios of nickel, cobalt, and manganese. This level of control is essential for achieving consistent battery performance and for complying with industry regulations.

Recyclers also benefit greatly from the capabilities of the XRF970. During the recycling process, the analyzer helps in the accurate sorting of waste lithium batteries by identifying their elemental composition. This is particularly important for ensuring that the recycled materials are of high enough quality to be reused in new batteries, thereby promoting a more sustainable and efficient battery lifecycle.

The advantages of using handheld XRF analyzers like the XRF970 extend beyond just speed and accuracy. These devices are designed for portability and durability, making them ideal for use in various environments, from the controlled conditions of a manufacturing plant to the rugged settings of a recycling facility. Their ability to perform on-site analysis eliminates the need for costly and time-consuming laboratory tests, thereby streamlining operations and reducing overall costs.

In conclusion, the role of handheld analyzers in ternary lithium battery analysis is crucial. They not only ensure the optimal performance of batteries but also contribute to the sustainability of the battery industry by facilitating efficient recycling practices. The XRF970 handheld lithium battery analyzer exemplifies the advancements in this field, offering a reliable and efficient solution for maintaining the integrity of lithium batteries throughout their lifecycle.

Advantages in Lithium Resource Competition

In the global race for lithium resources, handheld analyzers have emerged as a pivotal tool, particularly in on-site analysis and decision-making processes within the mining and trading sectors. Lithium, often referred to as "white oil," is a critical component in electric vehicle batteries and energy storage systems, making it a highly sought-after commodity. The strategic importance of lithium has led to a surge in demand, driving up prices and intensifying competition among nations and corporations.

Handheld lithium ore analyzers offer several distinct advantages in this competitive landscape. Firstly, they provide rapid analysis capabilities, enabling on-the-spot assessment of lithium content and ore grade. This immediacy is crucial for making informed decisions about mining operations and trading transactions, ensuring that resources are not wasted on low-value areas. The speed of analysis also allows for real-time adjustments to exploration plans, optimizing the use of resources and increasing the likelihood of discovering high-grade lithium deposits.

Secondly, these analyzers are designed to be robust and portable, capable of withstanding harsh field conditions. This adaptability is essential for operations in remote or extreme environments, where traditional laboratory analysis is impractical or impossible. The ability to conduct tests anytime and anywhere significantly reduces the time and cost associated with sample transportation and laboratory analysis, making the exploration process more cost-effective.

Moreover, handheld analyzers offer a high level of accuracy and a wide range of detectable elements, not only focusing on lithium but also analyzing other elements present in the ore. This comprehensive analysis helps in understanding the full composition of the ore, which is vital for determining its overall value and potential applications. The advanced technology of these devices ensures lower detection limits and better performance, providing reliable data that can be trusted in high-stakes decisions.

The integrated design of handheld spectrometers, coupled with their durability and portability, makes them ideal for use in the field. They are equipped with features such as thickened waterproof boxes, drop resistance, and wear resistance, ensuring their safety and longevity even in the most challenging outdoor environments. This robustness not only protects the investment in the equipment but also ensures consistent and reliable data collection, which is essential for maintaining a competitive edge in the lithium resource market.

In summary, handheld lithium ore analyzers play a crucial role in the global competition for lithium resources by enabling fast, accurate, and on-site analysis. Their adaptability, cost-effectiveness, and robust design make them indispensable tools for mining companies and traders alike, facilitating better decision-making and strategic positioning in the ever-evolving market for lithium.

Related Products

- Battery Lab Equipment Battery Capacity and Comprehensive Tester

- Lab Electrochemical Workstation Potentiostat for Laboratory Use

- XRD Sample Holder X-ray Diffractometer Powder Slide

Related Articles

- The Symphony of Coefficients: Why Your Electrolytic Cell Cannot Be a Monolith

- The Geometry of Control: Why 1 cm² Defines Electrochemical Success

- The Invisible Variable: Why Electrolytic Cell Hygiene Defines Your Data

- The Thermodynamics of Patience: Preventing Electrolytic Cell Overload

- The Architecture of Stability: Mastering Control with Double-Layer Electrolytic Cells