Table of Contents

Introduction to Handheld XRF Analyzers

Handheld XRF analyzers are sophisticated devices that have revolutionized the field of mining and geoscience. These analyzers, which are portable and compact, have immense importance in providing lab-quality results on-site with minimal sample preparation. They have proven to be a game-changer, especially in enhancing efficiency and accuracy in field analysis. This comprehensive guide delves into the features, applications, advantages, technological advancements, and selection criteria of handheld XRF analyzers, offering readers a deep understanding of their capabilities and significance in the field.

Key Features of Handheld XRF Analyzers

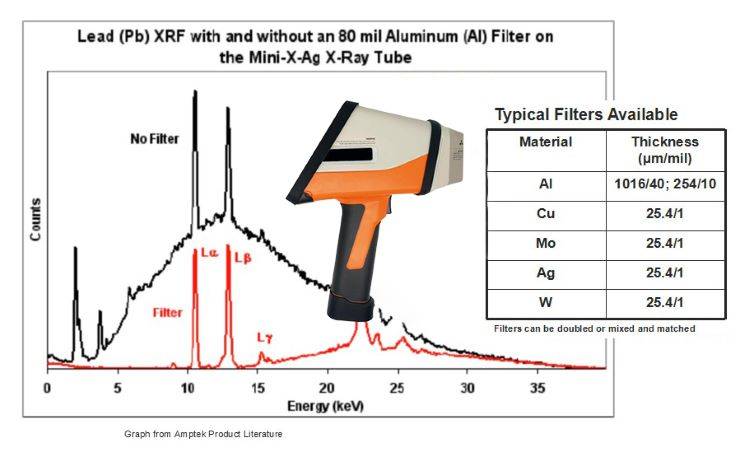

Handheld XRF analyzers are revolutionizing the field of mineral analysis and mining exploration with their advanced features and capabilities. These devices are equipped with high-performance micro X-ray tubes and intelligent multi-position filters, which are specifically optimized for key elements, ensuring excellent analytical performance. The use of these advanced components allows for precise and accurate measurements, making them indispensable tools in various applications including mineral exploration, geochemical testing, and ore grade control.

One of the standout features of these analyzers is their ability to perform fast analysis over a wide range of elements. With a simple one-click measurement, users can obtain stable measurement values and analyze up to 43 elements simultaneously without the need for complicated sample preparation. This capability significantly reduces the time and effort required in the field, making it easier to conduct swift qualitative screenings directly on-site.

The analyzers also incorporate Silicon Drift Detector (SDD) technology, which offers count rates and resolution far superior to traditional SiPIN detector technology. This advancement not only speeds up the analysis process but also improves the resolution and count rates, leading to lower detection limits for all elements analyzed. The combination of SDD detectors with the Fundamental Parameters (FP) method, which can be used for all mining sample types, results in one of the most powerful handheld instruments available for mineral analysis.

In addition to their analytical prowess, handheld XRF analyzers are designed with user convenience in mind. They feature ergonomic designs, lightweight construction, and a compact size that ensures good holding balance and ease of use in various field conditions. The inclusion of a 5-inch color touch screen allows for clear display even under strong outdoor light, enhancing usability in diverse environments.

Moreover, these devices are built to withstand harsh conditions with their sturdy and durable construction, featuring dustproof and waterproof performance that meets IP54 standards. They can operate continuously and normally within a wide temperature range of -10°C to 50°C, making them capable of handling the extreme environmental challenges often encountered in field operations.

The integration of intelligent operating systems further enhances the functionality of these analyzers. These systems are designed to be user-friendly, allowing for easy operation and customization. Users can tailor data fields and user profiles to create workflow solutions that are customized for their specific business needs. Additionally, the exclusive AXRSPEC PC software enables remote operation of the analyzer from a computer, and the WiFi capability allows for the seamless transfer and remote viewing of sample readings, adding to the overall efficiency and effectiveness of the analysis process.

In summary, handheld XRF analyzers are equipped with a range of advanced features that not only enhance their analytical performance but also improve user convenience and operational efficiency. These features make them an invaluable tool in the mining and exploration sectors, helping professionals to maximize productivity, reduce costs, and make more informed decisions in their operations.

Applications in Mining and Exploration

Handheld XRF analyzers play a pivotal role in various mining applications, significantly enhancing the efficiency and accuracy of grade identification, resource detection, and on-site determinations. These devices are particularly useful in the exploration and analysis of rare earth elements (REEs), which include the 15 lanthanides along with scandium and yttrium. REEs are critical components in numerous high-tech industries, including consumer electronics, catalytic converters, and rechargeable batteries. Handheld XRF analyzers enable real-time, on-site assessment of these elements, which are typically found in complex mineral combinations, each requiring specific extraction techniques and processing protocols.

In the realm of industrial minerals, such as limestone and phosphates, handheld XRF analyzers are becoming the preferred choice for in-quarry exploration and the assessment of raw materials. These instruments are crucial for maintaining product quality in industries like cement and fertilizers. With handheld XRF analyzers, mining operations can identify hazardous elements, examine blends, categorize raw materials, and distinguish between grade, sub-grade, and waste materials, thereby preventing unnecessary disposal and optimizing resource utilization.

Hardrock mining also benefits significantly from the use of handheld XRF analyzers. These devices provide the precision necessary for scrutinizing ore samples, whether in open pits or deep within underground mines. The data obtained from these analyzers is vital for overseeing processes, ensuring quality, and making crucial operational decisions, particularly in maintaining grade control. The swift analytics provided by handheld XRF analyzers, combined with a strategic sampling approach, can lead to substantial cost reductions and operational efficiencies.

For instance, the XRF60M analyzer is specifically designed for easy ore grade control, allowing for quick decision-making and accurate analysis of ore concentrates during the enrichment process. It can measure both primary elements and trace elements accurately using the fundamental parameters method, thereby improving mining operations by providing fast, accurate, and reliable on-site analysis of ore samples.

Handheld XRF analyzers, such as the AXR Terra600M, offer additional advantages by enabling rapid on-site analysis of mineral composition, which significantly reduces the number of samples that need to be sent to laboratories for analysis. This not only lowers analysis costs but also reduces analysis time, making it an invaluable tool in the mining industry.

In summary, handheld XRF analyzers are essential tools in modern mining and exploration. They facilitate real-time grade control, evaluate the feasibility of lower-grade resources, identify localized high-grade enrichments, define the boundaries between ore and waste, and enhance the management of run-of-mine stockpiles. With their excellent analytical performance, fast analysis capabilities, and wide range of applications, these devices are crucial for elevating the efficiency, sustainability, and productivity of mining operations.

Advantages Over Traditional Analytical Methods

Handheld XRF analyzers offer a significant advancement over traditional analytical methods, particularly in the field of metal material analysis and grade identification. These devices are not only fast and accurate but also non-destructive, making them ideal for various industries including mining, exploration, and geoscience.

Reliability and Precision: Handheld XRF analyzers are designed to provide results that are comparable to fire assay, a traditional and highly accurate method used in precious metal analysis. This capability helps prevent financial losses by accurately identifying under-karated or counterfeit materials. The precision of these devices ensures that the integrity of the materials being tested is maintained, which is crucial in industries where material quality directly impacts product value and safety.

Practical Design: Tailored for practical use in retail environments, XRF analyzers are factory-calibrated and ready for immediate use upon arrival. Their closed-beam design ensures safety by preventing x-ray exposure to customers or operators. This feature not only enhances user safety but also complies with health and safety regulations, making them suitable for a wide range of settings.

Detection Capabilities: One of the standout features of handheld XRF analyzers is their ability to efficiently detect gold plating on various substrates such as silver, copper, steel, tungsten, and others. This capability is crucial in identifying items that are gold-plated rather than solid gold, which can significantly affect their value and marketability.

Non-Destructive Testing: Unlike destructive testing methods like acid and fire assay, XRF analyzers allow for the testing of samples without causing any damage. This non-destructive nature preserves the original state of the samples, which is particularly beneficial when the tested materials are valuable or when multiple tests are required on the same sample.

Advanced Technology: The technological advancements in XRF instrumentation have significantly improved their sensitivity and stability. Modern handheld XRF analyzers utilize high-performance micro X-ray tubes and intelligent multi-position filters, which are optimized for key elements. This technology allows for the simultaneous analysis of up to 43 elements with just one-click measurement, providing stable and reliable results without the need for complicated sample preparation.

Efficiency and Cost-Effectiveness: In scenarios where large volumes of products need to be inspected, traditional handheld XRF analyzers might not suffice. However, advancements like the In-line 700 online XRF analyzers have been developed to meet these challenges. These systems enable real-time, online detection of large-scale products, significantly improving detection efficiency and reducing labor costs.

In conclusion, handheld XRF analyzers represent a significant leap forward in analytical technology, offering speed, accuracy, and non-destructive testing capabilities that are unmatched by traditional methods. Their practical design, advanced detection capabilities, and efficiency make them indispensable tools in various industries, ensuring high-quality results and operational efficiency.

Technological Advancements in Handheld XRF Analyzers

Handheld XRF analyzers have revolutionized the field of metal analysis and quality control, offering rapid, accurate results with minimal sample preparation. Recent technological advancements, particularly the integration of the fundamental parameters method (FP), have significantly enhanced the efficiency and accuracy of these devices.

The fundamental parameters method is a mathematical approach that allows for the analysis of elements without the need for calibration standards. This method uses a model that considers the fundamental properties of the sample, such as density, thickness, and elemental composition, to calculate the X-ray fluorescence (XRF) spectrum. By incorporating this method, handheld XRF analyzers can provide lab-quality results within seconds, making them ideal for on-site analysis in various industries, including mining, scrap metal recycling, and quality control in manufacturing.

One of the key advantages of the FP method is its ability to analyze a wide range of elements simultaneously. This is particularly beneficial in mining operations, where the presence of rare earth elements and key oxides needs to be determined from raw materials to final products. The use of a silicon drift detector (SDD) further enhances the analytical performance of these devices, offering superior count rates and resolution compared to traditional SiPIN detector technology. This improvement in detection limits and resolution enables more accurate and sensitive analysis, crucial for identifying economically viable resources promptly.

Moreover, the nondestructive nature of XRF analysis, combined with the speed and accuracy provided by the FP method, makes handheld XRF analyzers a preferred choice for non-invasive testing. Unlike destructive testing methods, XRF analysis leaves the sample intact, which is essential for further processing or resale of materials in industries like scrap metal recycling.

In summary, the technological advancements in handheld XRF analyzers, particularly the integration of the fundamental parameters method, have significantly improved the efficiency and accuracy of metal analysis. These devices are now capable of delivering rapid, lab-quality results on-site, with minimal training and sample preparation required. This makes them indispensable tools for various applications, from mining exploration to quality control in manufacturing and recycling industries.

Choosing the Right Handheld XRF Analyzer

Selecting the appropriate handheld XRF analyzer is crucial for ensuring accurate and efficient analysis in various industries, particularly in mining, exploration, and geoscience. The choice of analyzer depends on specific needs, budget, and the types of elements to be analyzed.

Analytical Performance

Handheld XRF analyzers equipped with high-performance micro X-ray tubes and intelligent multi-position filters offer excellent analytical performance. These features are optimized for key elements, ensuring precise and reliable results. The ability to analyze up to 43 elements simultaneously enhances the versatility and utility of these devices, making them suitable for a wide range of applications.

Speed and Efficiency

Speed is a critical factor in the selection of handheld XRF analyzers, especially in industries where rapid decisions are necessary. Analyzers with SDD (Silicon Drift Detector) technology offer superior count rates and resolution compared to traditional SiPIN detectors. This technology enables typical mining analyses to be completed in just a few seconds, significantly improving the efficiency of on-site determinations and decision-making processes.

Detection Limits and Resolution

The improved resolution and count rates provided by SDD technology also lead to lower detection limits for all elements analyzed. This capability is particularly important in mining and exploration, where the presence of rare earth elements and key oxides needs to be accurately determined from raw materials to final products. The use of the FP (Fundamental Parameters) method, which can be applied to all mining sample types, further enhances the analytical power of handheld XRF instruments.

Durability and Ease of Use

Handheld XRF analyzers are designed to withstand harsh environments, making them ideal for use in mining exploration and minerals extraction facilities. Their durability is complemented by user-friendly interfaces that require minimal training, allowing operators to perform one-click measurements and obtain stable results without the need for complicated sample preparation.

Conclusion

When choosing a handheld XRF analyzer, it is essential to consider the specific analytical needs, the speed of analysis, the range of elements to be detected, and the operating environment. Analyzers that offer high performance, speed, and durability, combined with ease of use, are particularly well-suited for applications in mining, exploration, and geoscience. By selecting the right handheld XRF analyzer, industries can enhance their efficiency, sustainability, and productivity, ultimately leading to better resource management and economic outcomes.

Future Trends in Handheld XRF Technology

Handheld XRF (X-ray Fluorescence) technology has been a cornerstone in the field of metal analysis and grade identification, offering rapid, accurate, and non-destructive testing methods. As the demand for more efficient and comprehensive inspection processes grows, particularly in industries dealing with large volumes of materials, the evolution of handheld XRF technology is poised to address these challenges.

One of the primary areas of development in handheld XRF technology is the enhancement of detection limits. Current models already boast impressive capabilities, with some featuring a 5W x-ray tube and a graphene window detector that ensures minimal detection thresholds for both heavy and light elements. Future advancements are likely to push these limits even further, potentially allowing for the detection of trace elements at levels significantly below those currently achievable. This could revolutionize applications in mining exploration, where the rapid identification of significant findings can drastically reduce the duration and cost of exploration campaigns.

User interfaces are another critical aspect set for transformation. As handheld XRF analyzers become more sophisticated, the need for intuitive and user-friendly interfaces becomes paramount. Future devices may incorporate advanced touch screen displays with enhanced graphical capabilities, making data interpretation and operation more straightforward for users. This could include features such as augmented reality overlays, which could provide real-time guidance and feedback during the analysis process, thereby reducing the need for extensive user training.

Integration with other technologies is also a significant trend. For instance, the connectivity of handheld XRF analyzers with software like AXRSPEK PC, which allows for remote control and data sharing, is likely to become more seamless. This integration could facilitate real-time data analysis and reporting, enabling immediate decision-making in critical applications such as quality control and scrap metal recycling.

Moreover, the development of more robust and durable handheld XRF devices is expected. These devices will be designed to withstand harsh environments, making them ideal for use in mining and other industrial settings. Improvements in materials and construction will ensure that these analyzers can operate reliably in extreme conditions, enhancing their utility in field applications.

In conclusion, the future of handheld XRF technology looks promising, with advancements in detection limits, user interfaces, technology integration, and device durability. These improvements will not only enhance the efficiency and effectiveness of metal analysis but also expand the range of applications for which these devices can be used. As the technology continues to evolve, it will remain a vital tool for industries requiring rapid, accurate, and non-destructive material analysis.

Related Products

- XRD Sample Holder X-ray Diffractometer Powder Slide

- Lab Electrochemical Workstation Potentiostat for Laboratory Use