Vacuum induction melting demands precision—especially when selecting crucible materials that won’t degrade when exposed to reactive alloys. This guide breaks down crucible design fundamentals, material-alloy interactions, and a practical framework for industrial selection, helping you optimize performance while avoiding costly contamination.

Crucible Design and Material Fundamentals

Crucible Types: Prefabricated vs. Knotted Systems

Prefabricated crucibles offer consistency and ease of use, ideal for standardized alloy batches. Knotted systems, assembled on-site, provide flexibility for custom shapes but require skilled installation.

Key considerations:

- Prefabricated: Lower labor costs, tighter quality control

- Knotted: Adjustable dimensions, better for irregular alloy volumes

Refractory Material Properties: Thermal Stability and Reactivity

The right refractory material must withstand extreme temperatures without reacting with molten alloys. Common options include:

- Magnesium Oxide (MgO): Resists basic slag but degrades with acidic alloys.

- Zirconia (ZrO₂): Exceptional thermal shock resistance, costly for large-scale use.

- Graphite: Conducts heat well but reacts with oxygen-sensitive alloys.

Ever wondered why some crucibles fail prematurely? Often, it’s a mismatch between the refractory’s chemical stability and the alloy’s reactivity.

Interactions Between Crucibles and Molten Alloys

Chemical Degradation Mechanisms in Vacuum Environments

Under vacuum, reduced pressure accelerates reactions between crucible materials and alloys. For example:

- Carbon pickup: Graphite crucibles can transfer carbon to steel alloys, altering mechanical properties.

- Erosion: MgO crucibles may dissolve when melting high-nickel alloys, introducing oxide inclusions.

Case Study: Magnesium Oxide Crucibles for Nickel Superalloys

In aerospace applications, MgO crucibles are preferred for nickel superalloys due to their high melting point (2,800°C) and low reactivity. However, trace silica in lower-grade MgO can form brittle silicates, compromising alloy integrity.

Solution: Use high-purity MgO (>99.5%) and pre-fire crucibles to minimize impurities.

Selection Framework for Industrial Applications

Decision Matrix: Alloy Composition vs. Refractory Compatibility

| Alloy Type | Recommended Crucible | Avoidance Criteria |

|---|---|---|

| Titanium | Yttria-coated graphite | Graphite (carbon pickup) |

| Aluminum | Boron nitride | SiO₂-based refractories |

| Nickel Superalloy | High-purity MgO | Low-grade MgO (silica risk) |

Cost-Performance Tradeoffs in Large-Scale Operations

- Budget-conscious ops: Dense zirconia crucibles offer longevity but require higher upfront investment.

- High-purity needs: Isostatically pressed MgO reduces contamination but increases unit costs by 20–30%.

Think of crucibles like alloy guardians—their material choice directly impacts your melt’s purity and your bottom line.

Conclusion: Actionable Steps for Optimal Crucible Performance

- Match material to alloy: Prioritize refractories with proven stability for your specific alloy family.

- Audit purity levels: Insist on certified high-purity materials for critical applications.

- Balance cost and lifespan: Calculate total cost of ownership, including replacement frequency.

For labs prioritizing precision, Kintek’s crucible solutions combine material expertise with rigorous testing—ensuring compatibility with demanding vacuum induction melting processes.

Products You Might Be Looking For:

https://kindle-tech.com/products/vacuum-induction-melting-furnace

https://kindle-tech.com/products/molybdenum-vacuum-furnace

https://kindle-tech.com/products/2200-graphite-vacuum-furnace

https://kindle-tech.com/products/2200-tungsten-vacuum-furnace

https://kindle-tech.com/products/vacuum-pressure-sintering-furnace

Related Products

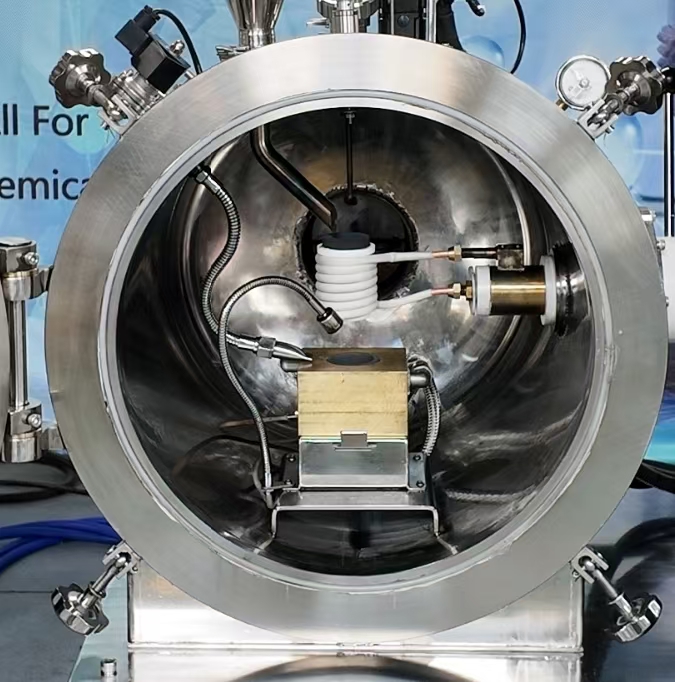

- Lab-Scale Vacuum Induction Melting Furnace

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- Custom Machined and Molded PTFE Teflon Parts Manufacturer with PTFE Crucible and Lid

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

- Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

Related Articles

- Application of Hot Isostatic Pressing Technology in Nickel-Based Casting High-Temperature Alloys

- How Vacuum Induction Melting Prevents Catastrophic Material Failures in Critical Components

- Vacuum Melting Furnace: A Comprehensive Guide to Vacuum Induction Melting

- Vacuum Induction Melting Furnace: Principle, Advantages, and Applications

- How Vacuum Induction Melting (VIM) Transforms High-Performance Alloy Production