Introduction

In industries where metal purity dictates product lifespans—from jet engines to nuclear reactors—Vacuum Induction Melting (VIM) has emerged as the gold standard. This article demystifies VIM’s superiority in defect reduction, operational efficiency, and scalability, backed by real-world aerospace and energy sector implementations. Whether you’re evaluating metallurgical methods or optimizing existing systems, here’s what makes VIM indispensable for mission-critical alloys.

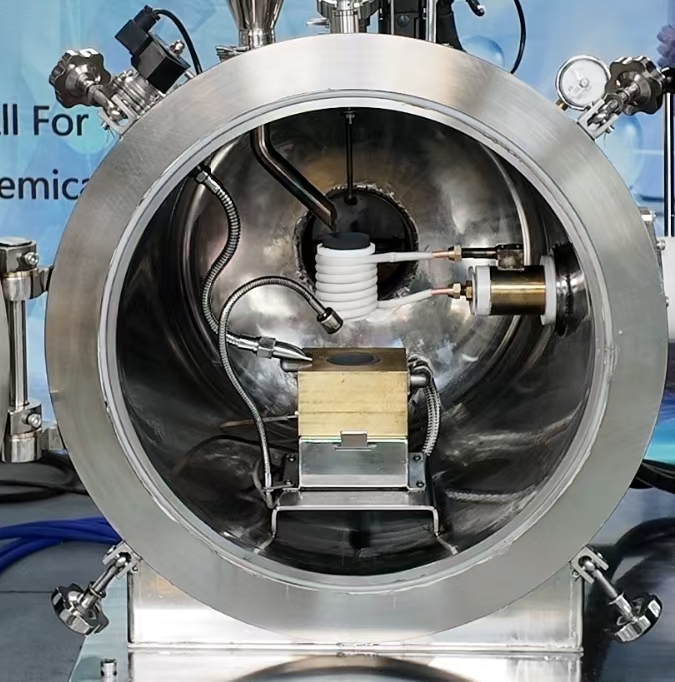

Vacuum Induction Melting: The Cornerstone of Premium Metallurgy

How Electromagnetic Stirring Reduces Inclusion Defects

VIM’s electromagnetic stirring eliminates slag and non-metallic inclusions—the primary culprits behind alloy fatigue failures. Unlike static melting, Lorentz forces actively homogenize molten metal, achieving inclusion sizes below 5 microns (critical for turbine blades). Ever wondered why aerospace manufacturers reject conventionally melted titanium? Inclusions larger than 10 microns act as stress concentrators, cutting component lifespans by 40%.

Vacuum Environment vs. Gas Purge Systems: Oxidation Control Benchmarks

While argon purging reduces oxidation, VIM’s 10⁻³ mbar vacuum environment slashes oxygen pickup by 90% compared to gas-shielded arc furnaces. For nickel superalloys, this means oxide scale thickness stays under 2 nm versus 20 nm in traditional methods—a non-negotiable for corrosion-resistant reactor components.

Industry-Specific Implementation Strategies

Aerospace Titanium Alloy Casting: NASA and Airbus Case Studies

NASA’s Mars rover actuators use VIM-processed Ti-6Al-4V, where even 0.1% oxygen variation causes ductility drops. Airbus reports 30% fewer post-casting HIP (Hot Isostatic Pressing) treatments after switching to VIM, citing fewer subsurface voids.

Power Plant Turbine Blade Manufacturing Protocols

GE’s H-class turbines demand single-crystal blades with sulfur content below 10 ppm. VIM’s vacuum desulfurization achieves 2 ppm consistently—impossible with electroslag remelting.

Technical Innovations in Modern VIM Systems

AI-Driven Impurity Detection During Refining

Machine learning algorithms now predict carbon pickup from crucible linings, adjusting power input in real-time. Trials show a 60% reduction in off-spec batches.

Graphene-Coated Crucibles: Tripling Service Life

Traditional zirconia crucibles degrade after 50 melts. Kintek’s graphene-coated variants withstand 150+ cycles by preventing metal-carbide formation at 1,600°C.

Cost-Benefit Analysis for Production Scaling

Energy Consumption per Ton: VIM vs. Traditional Arc Furnaces

At 1,200 kWh/ton, VIM consumes 20% more energy than arc furnaces—but the 80% lower rejection rate offsets costs. For a 10,000-ton/year aerospace foundry, this saves $12M annually in rework.

Scrap Metal Reutilization Rate Optimization

VIM’s precise composition control allows 95% scrap integration versus 70% in arc furnaces. Lockheed Martin’s F-35 program cut virgin material costs by 18% using this approach.

Conclusion: Future-Proofing Metallurgy with VIM

VIM isn’t just about purity—it’s about predictable performance. For labs and foundries, investing in VIM-ready equipment like Kintek’s crucibles and vacuum systems future-proofs operations against tightening industry specs. Ready to benchmark your alloy quality against NASA-grade standards? Start with a scrap audit—most operations uncover 15–20% cost savings from improved remelting efficiency alone.

Products You Might Be Looking For:

https://kindle-tech.com/products/vacuum-induction-melting-furnace

https://kindle-tech.com/products/molybdenum-vacuum-furnace

https://kindle-tech.com/products/molybdenum-vacuum-furnace

https://kindle-tech.com/products/molybdenum-vacuum-furnace

https://kindle-tech.com/products/vacuum-pressure-sintering-furnace

https://kindle-tech.com/products/vacuum-pressure-sintering-furnace

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Arc Induction Melting Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

Related Articles

- Melting process and maintenance of vacuum induction melting furnace

- Vacuum Induction Melting Furnace: Principle, Advantages, and Applications

- How Vacuum Induction Melting Prevents Catastrophic Material Failures in Critical Components

- How Vacuum Induction Melting Ensures Unmatched Reliability in Critical Industries

- How Vacuum Induction Melting Powers Superior Material Performance in Critical Industries