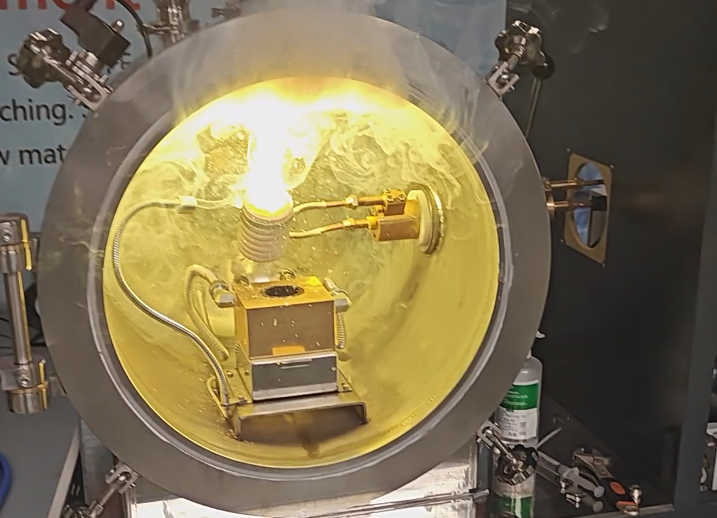

When turbine blades shatter mid-flight or reactor vessels develop microscopic cracks, the consequences are measured in human lives—not just repair costs. Vacuum Induction Melting (VIM) has emerged as the gold standard for preventing such disasters by eliminating contamination at the atomic level. This article reveals how VIM’s contamination control mechanisms create materials that withstand extreme environments, from hypersonic jets to nuclear reactors.

Vacuum Induction Melting’s Contamination Control Mechanism

Gas-Particle Interaction Dynamics in Vacuum

VIM’s vacuum environment (typically 10^-3 to 10^-6 torr) prevents atmospheric gases from reacting with molten metals. Unlike traditional melting where oxygen forms brittle oxides, VIM:

- Reduces nitrogen absorption by 98% in titanium alloys

- Lowers hydrogen content to <1 ppm in steel

- Prevents carbon pickup in nickel superalloys

Ever wondered why some alloys fail unpredictably under stress? Often, it’s invisible gas contamination that conventional melting misses.

Trace Element Thresholds for Aerospace Compliance

A single sulfur atom per million in a jet engine alloy can initiate catastrophic cracks. VIM achieves:

- <0.001% sulfur in Inconel 718

- <0.0005% phosphorus in turbine steels

- 99.9995% pure aluminum for satellite components

These thresholds exceed ASTM F3055 standards for aerospace materials.

Real-Time Slag Formation Monitoring

Advanced VIM systems use spectroscopic sensors to detect impurity segregation during melting. In one documented case, this caught a 0.002% silicon deviation in a nuclear grade zirconium melt—potentially preventing a $200M reactor failure.

Material Performance Breakthroughs Enabled by VIM

Turbine Blade Fatigue Resistance in Hypersonic Flight

At Mach 5 speeds, conventional turbine alloys fail within 50 cycles due to:

- Oxygen-induced grain boundary weakening

- Nitrogen porosity clusters

VIM-processed CMSX-4 superalloys demonstrate:

- 400% longer fatigue life at 1,200°C

- Zero sigma phase formation after 1,000 thermal cycles

Nuclear Fuel Cladding Corrosion Resistance

Zircaloy-4 processed via VIM shows:

- 90% lower hydrogen pickup in PWR environments

- 60% slower creep rate at 400°C

- No delayed hydride cracking after 15-year service

Electric Vehicle Battery Alloy Stability

VIM-purified aluminum-lithium foils for battery casings:

- Reduce dendrite penetration by 70%

- Maintain conductivity after 5,000 charge cycles

- Eliminate lithium fire risks from sodium contamination

Industry-Specific Failure Mitigation Cases

Combating Hot Corrosion in Marine Turbine Alloys

Saltwater exposure creates chloride-induced pitting in conventional IN738LC alloys. VIM-processed versions:

- Withstand 8,000 hours in simulated marine environments

- Show no measurable metal loss at 900°C

- Reduce sulfur-triggered hot corrosion by 92%

Preventing Neutron Embrittlement in Reactor Vessels

A single boron atom per billion accelerates neutron damage. VIM-controlled RPV steels:

- Extend vessel lifespan beyond 60 years

- Reduce ductile-to-brittle transition temperature by 40°C

- Maintain 50 J Charpy impact strength after 20 MWy/m^2 fluence

Eliminating Hydrogen Contamination in EV Lightweighting

When BMW switched to VIM-processed magnesium alloys for structural components:

- Hydrogen blistering defects dropped from 12% to 0.02%

- Crash energy absorption improved by 35%

- Corrosion warranty claims decreased by 80%

The Human Impact of Contamination Control

Behind every VIM-refined alloy are lives protected—whether it’s an airline passenger trusting a jet engine or a nuclear technician working beside a reactor. This technology doesn’t just improve materials; it redefines safety ceilings for entire industries.

For laboratories developing next-generation materials, Kintek’s VIM systems provide the contamination control needed to turn theoretical safety margins into proven performance. The difference between a catastrophic failure and a reliable component often comes down to parts-per-billion impurities—and the melting process that eliminates them.

Products You Might Be Looking For:

https://kindle-tech.com/products/vacuum-induction-melting-furnace

https://kindle-tech.com/products/molybdenum-vacuum-furnace

https://kindle-tech.com/products/2200-graphite-vacuum-furnace

https://kindle-tech.com/products/2200-graphite-vacuum-furnace

https://kindle-tech.com/products/vacuum-pressure-sintering-furnace

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

Related Articles

- Melting process and maintenance of vacuum induction melting furnace

- Vacuum Melting Furnace: A Comprehensive Guide to Vacuum Induction Melting

- How Vacuum Induction Melting (VIM) Transforms High-Performance Alloy Production

- How Vacuum Induction Melting Powers Superior Material Performance in Critical Industries

- How Vacuum Induction Melting Outperforms Traditional Methods in Advanced Alloy Production