In short, yes, roller mills are typically more energy-efficient than hammer mills, but the idea that they are more efficient for producing smaller particle sizes is a common and critical misunderstanding. While roller mills excel at creating a uniform, coarse grind with minimal energy, hammer mills are generally the superior tool for achieving very fine and ultra-fine particle reductions, though often at a higher energy cost.

The choice between a roller mill and a hammer mill is not about which is universally "better," but which is precisely suited to your target particle size and material type. Roller mills offer energy-efficient precision for coarse grinds, while hammer mills provide versatile power for fine grinds.

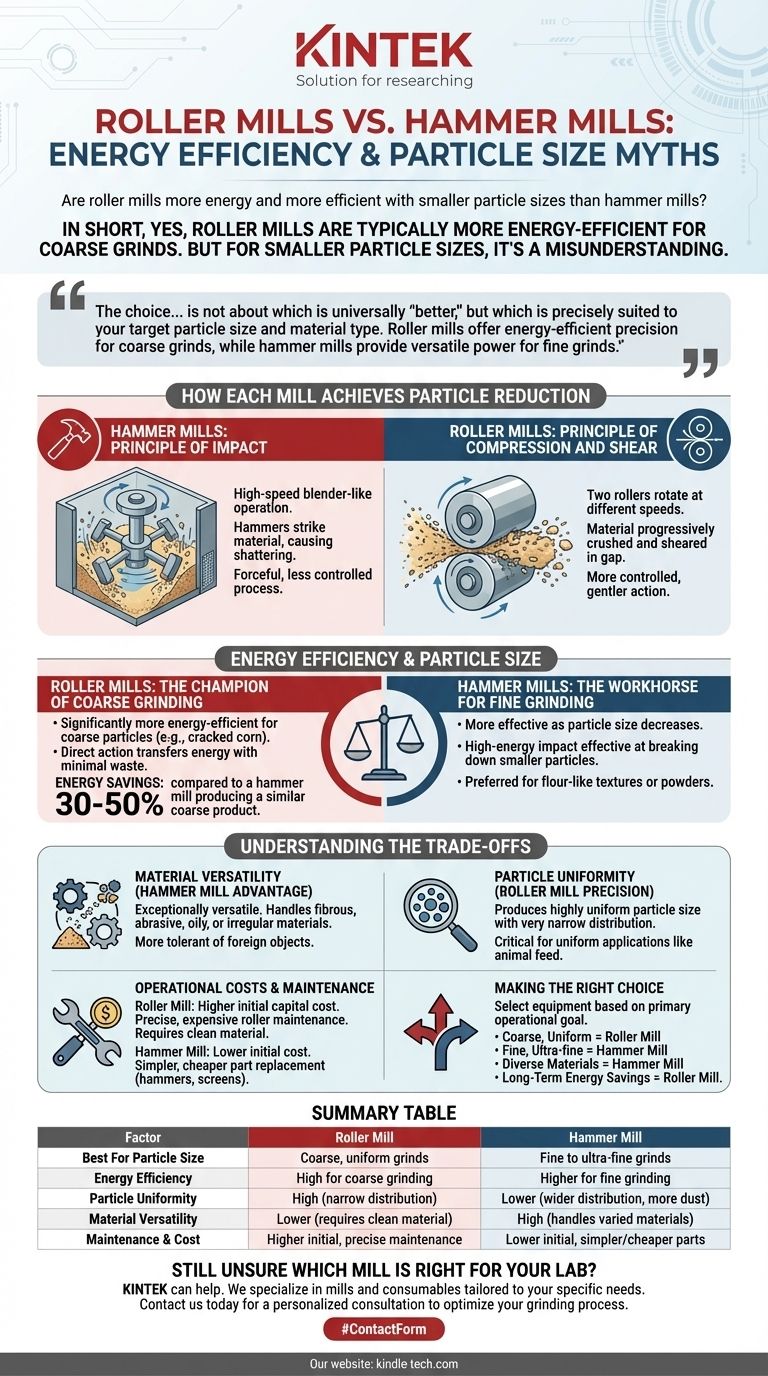

How Each Mill Achieves Particle Reduction

To understand their respective efficiencies, you must first understand their fundamentally different mechanisms. They do not perform the same job in the same way.

Hammer Mills: The Principle of Impact

A hammer mill operates like a high-speed blender. It uses swinging or fixed hammers rotating at high velocity to strike material, causing it to shatter upon impact against the hammers and the grinding chamber wall.

The material remains in the chamber until it is small enough to pass through a screen that dictates the maximum particle size. This is a forceful, less controlled process.

Roller Mills: The Principle of Compression and Shear

A roller mill uses two or more cylindrical rollers (corrugated or smooth) rotating at different speeds. Material is pulled into the gap between them, where it is progressively crushed and sheared.

The size of the final particle is determined primarily by the distance, or "gap," set between the rollers. This is a more controlled, gentler action.

Energy Efficiency and Particle Size

The efficiency of each mill is directly tied to the target particle size. There is a clear point where the advantage shifts from one to the other.

Roller Mills: The Champion of Coarse Grinding

For creating coarse particles (e.g., cracked corn), the roller mill is significantly more energy-efficient. The direct compression and shearing action transfers energy into particle reduction with minimal waste.

This process generates less heat, less noise, and, most importantly, fewer unwanted fine particles (dust). This can result in energy savings of 30-50% compared to a hammer mill producing a similar coarse product.

Hammer Mills: The Workhorse for Fine Grinding

As the desired particle size decreases, the efficiency of a roller mill drops significantly. To make particles finer, the rollers must be set closer, which reduces the mill's throughput and increases the energy required per ton.

Conversely, a hammer mill becomes more effective in this range. The high-energy impact is very good at breaking down smaller particles into even finer ones. For producing flour-like textures or powders, a hammer mill is almost always the more effective and often more efficient choice.

Understanding the Trade-offs

The decision involves more than just energy consumption and particle output. Operational realities and material characteristics are just as important.

Material Versatility: Hammer Mill's Advantage

Hammer mills are exceptionally versatile. They can process a wide range of materials, including those that are fibrous, abrasive, oily, or irregularly shaped.

They are also far more tolerant of foreign materials like small stones or metal fragments, which might cause catastrophic damage to a roller mill.

Particle Uniformity: Roller Mill's Precision

The single greatest advantage of a roller mill is its ability to produce a highly uniform particle size with a very narrow distribution curve.

This is critical in applications like animal feed, where consistent particle size ensures uniform digestion and nutrient absorption. A hammer mill, by contrast, creates a much wider distribution of particle sizes, including a significant percentage of undesirable dust.

Operational Costs and Maintenance

While a roller mill saves on energy, it typically has a higher initial capital cost.

Maintenance is also a key differentiator. Roller mills require clean, pre-screened material to avoid damage. Re-corrugating or replacing rollers is a precise and expensive task. Hammer mills are simpler to maintain; hammers and screens are relatively inexpensive and easy to replace.

Making the Right Choice for Your Operation

Select your grinding equipment based on your primary operational goal.

- If your primary focus is a uniform, coarse product (e.g., dairy cattle feed): A roller mill is the superior choice for its energy efficiency and consistent particle size.

- If your primary focus is a fine or ultra-fine grind (e.g., piglet feed, flour, powders): A hammer mill is the necessary and more effective tool for the job.

- If your primary focus is processing diverse or uncleaned materials: A hammer mill provides the flexibility and durability required to handle varied inputs.

- If your primary focus is minimizing operational cost for a consistent, coarse product: The long-term energy savings of a roller mill will likely outweigh its higher initial investment.

Ultimately, matching the mill's inherent strengths to your specific product requirements is the key to an efficient and profitable operation.

Summary Table:

| Factor | Roller Mill | Hammer Mill |

|---|---|---|

| Best For Particle Size | Coarse, uniform grinds | Fine to ultra-fine grinds |

| Energy Efficiency | High for coarse grinding | Higher for fine grinding |

| Particle Uniformity | High (narrow distribution) | Lower (wider distribution, more dust) |

| Material Versatility | Lower (requires clean, pre-screened material) | High (handles fibrous, abrasive, oily materials) |

| Maintenance & Cost | Higher initial cost, precise maintenance | Lower initial cost, simpler/cheaper part replacement |

Still Unsure Which Mill is Right for Your Lab?

Choosing the right grinding equipment is critical for your lab's efficiency, product quality, and budget. KINTEK, your trusted partner for laboratory equipment, can help you make the perfect choice.

We specialize in providing mills and consumables tailored to your specific materials and target particle sizes. Our experts will analyze your needs to ensure you get the most energy-efficient and effective solution for your operation.

Contact us today using the form below for a personalized consultation. Let KINTEK help you optimize your grinding process for superior results.

Visual Guide

Related Products

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Four-Body Horizontal Jar Mill

- Laboratory Single Horizontal Jar Mill

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Grinding Mill Mortar Grinder for Sample Preparation

People Also Ask

- How does a high-efficiency mixer impact the quality of tungsten disulfide (WS2) powder? Master Precursor Homogeneity

- What is the main difference between ball mill and rod mill? Choose the Right Grinding Mill for Your Material

- Why use ball milling for NMC cathode materials? Achieve Precision Particle Sizing for Composite Cathodes

- What is a mortar and pestle used for in a lab? A Guide to Precision Grinding and Mixing

- What is the role of an Attritor Mill in Cu-CNT preparation? Optimize Dispersion through Mechanical Alloying

- Why is the grinding process essential for catalyst support pretreatment? Maximize Zirconia-Based Catalyst Efficiency

- What is the technical significance of adjusting ball mill rotation speeds to low levels? Optimize Composite Cathodes

- How is the energy for particle collisions generated in a jet mill? Mastering Kinetic Energy for Precise Grinding