Yes, but only specific steels are chosen for this process. While all steel contains carbon, the manufacturing technique known as carburizing is exclusively applied to low-carbon steels. The purpose is not simply to add carbon, but to create a component with two distinct sets of properties: an extremely hard, wear-resistant surface and a soft, tough, and ductile core.

Carburizing is a case-hardening process that diffuses carbon into the surface of a low-carbon steel. This allows the surface to become hard after quenching while the core remains tough, creating a component resistant to both surface wear and catastrophic fracture.

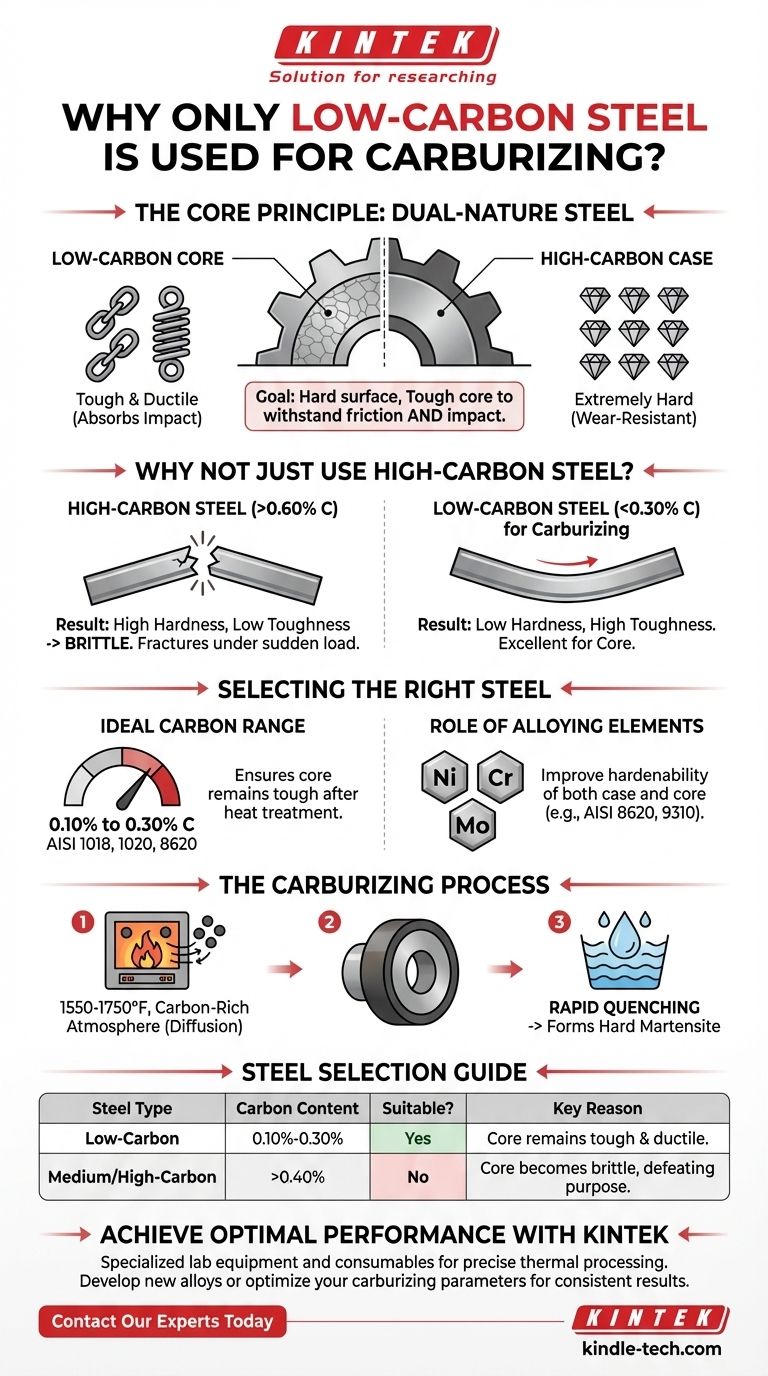

The Core Principle: Creating a Dual-Nature Steel

Carburizing solves a fundamental engineering dilemma. Many applications, like gears or bearings, demand a material that can withstand surface friction and wear while also resisting impact and shock without shattering.

Why Not Just Use High-Carbon Steel?

A simple high-carbon steel (containing >0.60% carbon) can be made very hard through quenching. However, this hardness comes with a significant trade-off: brittleness. A part made entirely of high-carbon steel would be strong but could easily fracture under sudden load or impact.

The "Case Hardening" Goal

The goal of carburizing is to create a "case" — a thin, hardened outer layer — on the steel component. This provides the necessary surface hardness for wear resistance.

Beneath this case lies the original low-carbon "core," which does not harden significantly during quenching. This core remains relatively soft, ductile, and tough, giving it the ability to absorb impact energy without breaking.

How Carbon Content Dictates Properties

The final hardness of a quenched steel is almost entirely a function of its carbon content.

- Low Carbon (<0.30% C): Results in low hardness but high toughness.

- High Carbon (>0.60% C): Results in high hardness but low toughness (brittleness). Carburizing creates a composite material by forming a high-carbon layer on a low-carbon base.

Selecting the Right Steel for Carburizing

The success of the process hinges on starting with the correct material. The steel must have a low enough carbon content to ensure the core remains tough after the final heat treatment.

The Ideal Carbon Range

Steels selected for carburizing typically have a carbon content between 0.10% and 0.30%. Common grades include AISI 1018, 1020, and 8620.

The Role of Alloying Elements

While plain carbon steels can be carburized, alloy steels like AISI 8620 or 9310 are often preferred for more demanding applications.

Alloys such as nickel, chromium, and molybdenum do not directly participate in carburizing but significantly improve the hardenability of both the case and the core. This allows for greater strength and the ability to harden larger cross-sections effectively.

The Process at a Glance

The steel part is heated to a high temperature (typically 1550-1750°F or 850-950°C) inside a sealed furnace with a carbon-rich atmosphere. Carbon atoms from the atmosphere diffuse into the surface of the steel, with the depth of penetration controlled by time and temperature. After carburizing, the part is quenched (rapidly cooled) to transform the high-carbon case into a very hard structure called martensite.

Understanding the Trade-offs and Limitations

Carburizing is a powerful but specific tool. Applying it to the wrong material defeats its purpose and can lead to component failure.

Why You Cannot Carburize Medium or High-Carbon Steel

Attempting to carburize a steel that already contains significant carbon (e.g., 0.40% C or higher) is counterproductive.

After quenching, the core of such a steel would become hard and brittle on its own. This completely negates the primary benefit of carburizing, which is to maintain a tough core. The result is a part that is brittle through its entire thickness.

Process Complexity and Cost

Carburizing is a multi-step process: carburize, quench, and often temper. This is more time-consuming and expensive than a simple through-hardening treatment used for medium-carbon steels.

Potential for Distortion

The high temperatures involved, followed by rapid quenching, introduce significant thermal stress. This can cause the part to warp or distort, often requiring final grinding or machining to achieve final dimensional accuracy.

Making the Right Choice for Your Goal

Selecting the correct hardening strategy depends entirely on the mechanical requirements of the final component.

- If your primary focus is extreme surface wear resistance combined with excellent core toughness (gears, shafts, bearings): Carburizing a low-carbon alloy steel is the premier solution.

- If your primary focus is good hardness and strength throughout the entire part (tools, bolts, structural plates): A medium-carbon steel (like 1045 or 4140) that is through-hardened is a more direct and economical choice.

- If your primary focus is formability and weldability with no specific hardness requirement (general fabrication): A standard low-carbon steel used in its as-supplied state is sufficient.

By understanding the relationship between carbon and hardness, you can confidently select the precise steel and thermal process to match your engineering objective.

Summary Table:

| Steel Type | Carbon Content | Suitable for Carburizing? | Key Reason |

|---|---|---|---|

| Low-Carbon Steel | 0.10% - 0.30% | Yes | Core remains tough and ductile after hardening. |

| Medium/High-Carbon Steel | >0.40% | No | Core becomes brittle, defeating the purpose of case hardening. |

Achieve Optimal Performance for Your Critical Components

Choosing the right steel and heat treatment process is essential for creating durable, high-performance parts. The carburizing process requires precise control and the correct starting materials to ensure a hard, wear-resistant surface and a tough, impact-absorbing core.

KINTEK specializes in providing the advanced lab equipment and consumables necessary for precise thermal processing. Whether you are developing new alloys or optimizing your carburizing parameters, our solutions help you achieve consistent, reliable results.

Let's enhance your manufacturing process together. Contact our experts today to discuss your specific laboratory and production needs!

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

People Also Ask

- What is the difference between upflow and horizontal furnace? Find the Perfect Fit for Your Home's Layout

- How do you clean a tubular furnace tube? A Step-by-Step Guide to Safe and Effective Maintenance

- What temperature is tube annealing? A Guide to Material-Specific Ranges for Optimal Results

- What is quartz tube heating? Achieve Instant, Targeted Heat with Infrared Radiation

- How do you clean a quartz tube furnace? Prevent Contamination & Extend Tube Lifespan