Yes, activated carbon can burn. Because it is composed primarily of carbon, it is an inherently combustible material, much like the charcoal from which it is often derived. However, its unique porous structure and its function as an adsorbent mean that its flammability is highly dependent on its specific type, condition, and what substances it has trapped.

The critical question is not if activated carbon will burn, but under what conditions it will burn. Its behavior is dictated less by its fundamental nature and more by factors like particle size, retained heat, and the flammability of the materials it has adsorbed.

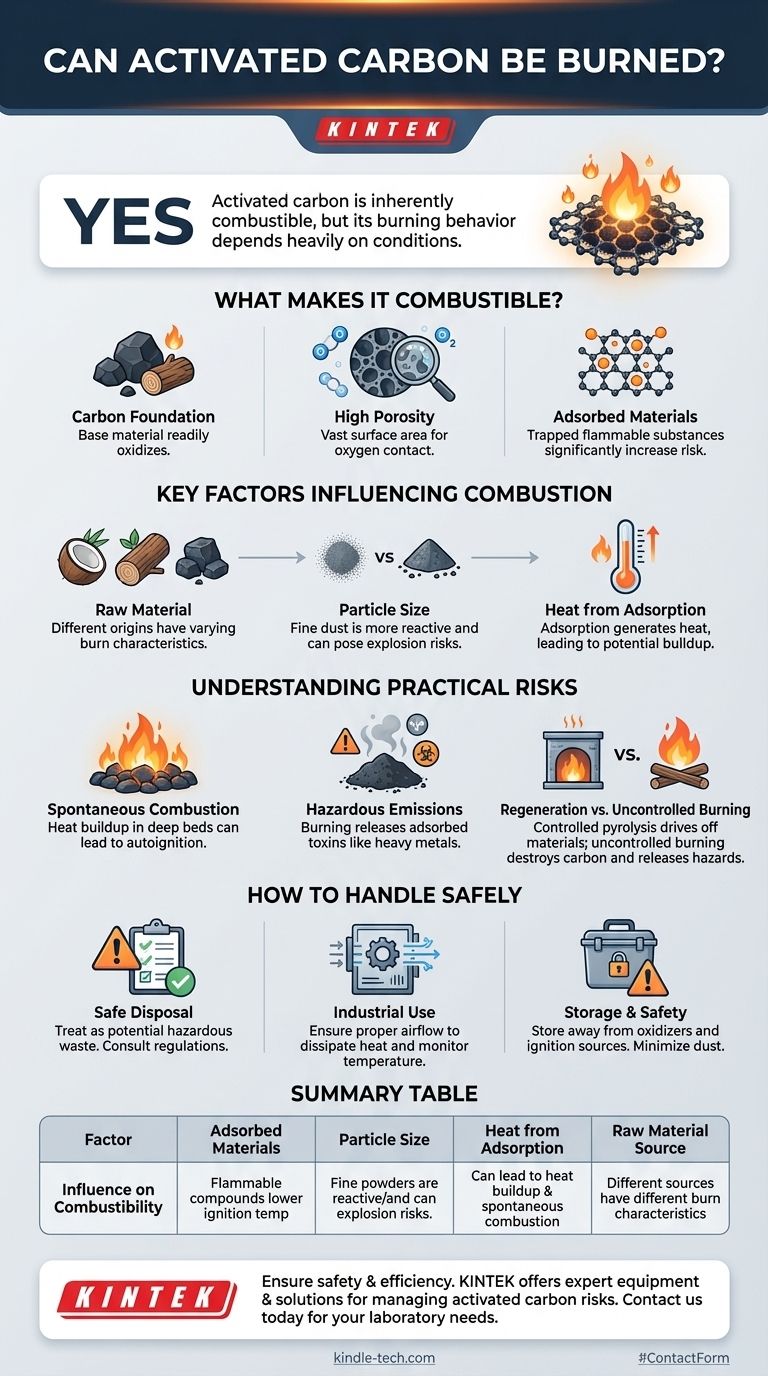

What Makes Activated Carbon Combustible?

To understand the risks, we first need to look at the properties that make activated carbon susceptible to combustion. It's a combination of its core composition and its unique physical structure.

A Foundation of Carbon

Activated carbon is an amorphous form of elemental carbon. Just like coal, wood, and charcoal, this carbon base will readily oxidize (burn) when exposed to sufficient heat and an oxygen source.

The Role of High Porosity

The "activation" process creates a vast network of microscopic pores, giving the material an incredibly high surface area. This allows for excellent contact with oxygen, a key ingredient for sustaining combustion once ignition has occurred.

The Impact of Adsorbed Materials

This is the most significant variable. Activated carbon is designed to trap other molecules. If it adsorbs flammable organic compounds (like solvents), those substances can lower the carbon's overall ignition temperature, making a fire much more likely.

Key Factors Influencing Combustion

As the research indicates, not all activated carbon behaves the same. Several factors determine how easily it will ignite and how vigorously it will burn.

The Original Raw Material

Activated carbon can be made from coconut shells, wood, or coal. These different starting materials produce carbons with varying densities, hardness, and ash content, all of which influence their thermal properties and burn characteristics.

Particle Size and Form

The physical form is a major factor. Fine powders or dusts have a massive collective surface area, making them far more reactive and easier to ignite than granular activated carbon (GAC). In certain conditions, airborne carbon dust can even pose an explosion risk.

Heat from Adsorption

The process of adsorption itself generates a small amount of heat. In a large, deep bed of activated carbon with poor airflow, this heat can accumulate, a process known as exothermic reaction.

Understanding the Practical Risks

The combustibility of activated carbon is not just a theoretical property; it has serious safety implications in industrial and disposal contexts.

The Danger of Spontaneous Combustion

This is the most critical risk. If activated carbon adsorbs materials that readily oxidize (such as ketones or certain oils), the slow heat generated can build up within a carbon bed. If this heat cannot dissipate, the temperature can rise to the point of autoignition, causing the carbon to ignite without an external spark or flame.

Hazardous Emissions from Burning

Never assume burning activated carbon is a clean process. If the carbon has adsorbed heavy metals, chlorinated compounds, or other toxins, burning it will release these substances into the atmosphere, often in more concentrated and dangerous forms.

Regeneration vs. Uncontrolled Burning

In industrial settings, carbon is often "regenerated" using high heat in a controlled, oxygen-starved environment. This process (pyrolysis) drives off the adsorbed materials without burning the carbon itself. This is fundamentally different from uncontrolled combustion, which destroys the carbon and creates hazardous emissions.

How to Handle Activated Carbon Safely

Your approach should be guided by your specific goal and an awareness of the material's condition.

- If your primary focus is safe disposal: Treat used activated carbon as potentially hazardous waste, especially if its exposure history is unknown. Never attempt to burn it for disposal; instead, consult your local environmental regulations for proper handling.

- If your primary focus is industrial use: Ensure carbon bed systems are engineered with proper airflow to dissipate heat. Monitor for temperature increases that could signal the risk of spontaneous combustion, particularly when adsorbing reactive organic compounds.

- If your primary focus is general safety and storage: Store activated carbon away from strong oxidizing agents, flammable materials, and sources of ignition. Handle it in a way that minimizes dust creation.

Understanding that activated carbon's combustibility is defined by its specific condition, not just its nature, is the key to handling it safely and effectively.

Summary Table:

| Factor | Influence on Combustibility |

|---|---|

| Adsorbed Materials | Flammable compounds can lower ignition temperature. |

| Particle Size | Fine powders are more reactive and pose a dust explosion risk. |

| Heat from Adsorption | Can lead to heat buildup and spontaneous combustion. |

| Raw Material Source | Coconut, wood, or coal-based carbons have different burn characteristics. |

Ensure the safety and efficiency of your laboratory processes.

Activated carbon is a powerful tool, but its combustibility requires expert handling and the right equipment. KINTEK specializes in providing high-quality lab equipment and consumables, including safe storage solutions and systems designed to manage the risks associated with activated carbon.

Our experts can help you select the right products and develop protocols to prevent hazardous situations like spontaneous combustion. Contact us today to discuss your specific laboratory needs and how we can support your safety and operational goals.

Visual Guide

Related Products

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Graphite Vacuum Continuous Graphitization Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What are two disadvantages of metal? Understanding Corrosion and Weight Limitations

- How does hardness change with temperature? Understand the Inverse Relationship to Prevent Failure

- What are the disadvantages of using metal? Understanding Corrosion, Weight, and Cost Challenges

- What is the difference between metallic and non-metallic coating? A Guide to Sacrificial vs. Barrier Protection

- What are the advantages disadvantages and uses of sheet metal? The Ultimate Guide to Material Selection