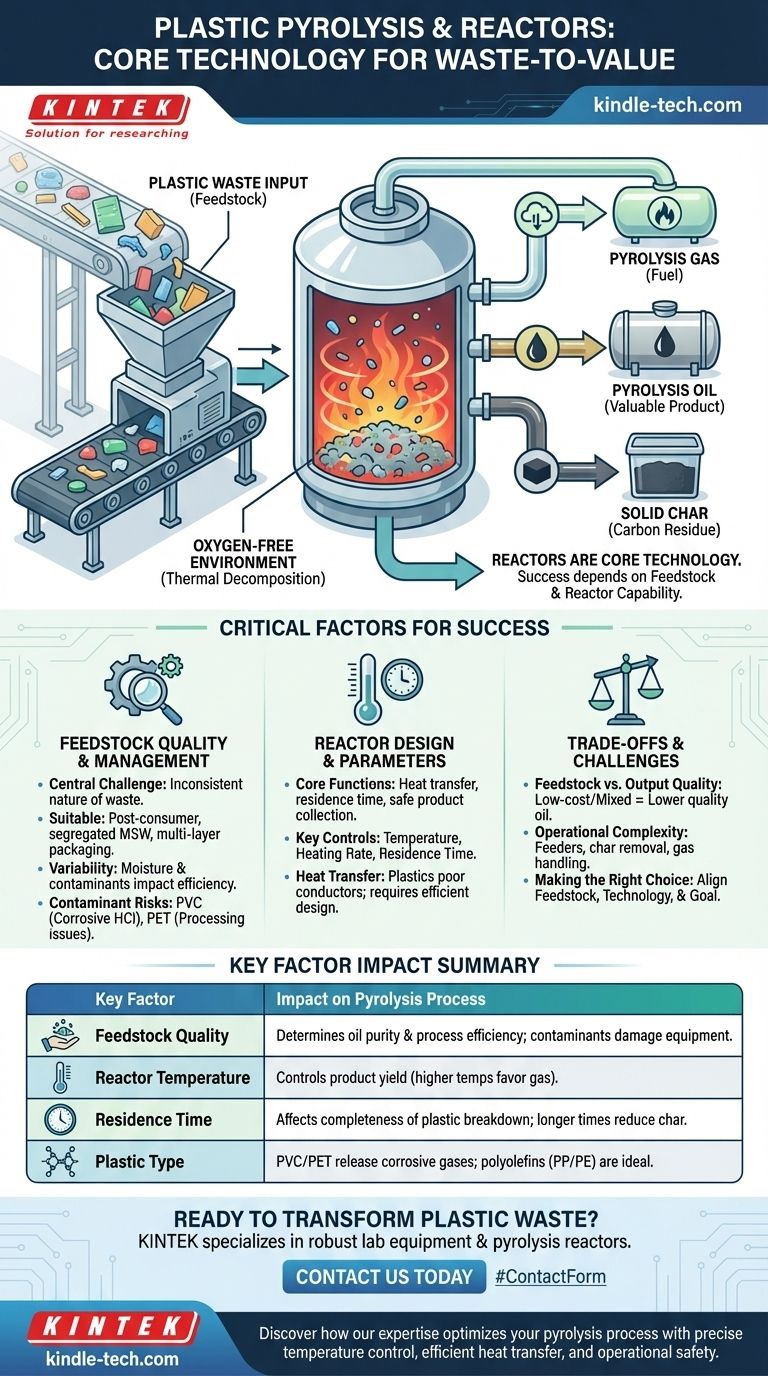

Yes, reactors are not just used for the pyrolysis of plastic waste; they are the core technology that makes the entire process possible. These specialized vessels are designed to heat plastic in an oxygen-free environment, thermally breaking it down into more valuable products like pyrolysis oil, gas, and solid char. The success of the operation, however, is critically dependent on the type of plastic waste used and the reactor's ability to handle its variability.

The central challenge in plastic pyrolysis is not the reactor itself, but managing the inconsistent nature of the plastic feedstock. Achieving a consistent, valuable output depends almost entirely on understanding and controlling the quality of the waste material you put in.

The Role of the Reactor in Pyrolysis

A pyrolysis reactor is more than just a hot container. It is an engineered system designed to control a complex chemical transformation under precise conditions.

What is Pyrolysis?

Pyrolysis is the thermal decomposition of materials at elevated temperatures in the absence of oxygen. Without oxygen, the material doesn't combust (burn); instead, its long polymer chains break apart into smaller, simpler molecules.

The Reactor's Core Functions

The reactor's primary job is to provide a controlled environment. It must efficiently transfer heat to the plastic feedstock, manage the residence time the material spends at temperature, and safely collect the resulting liquid, gas, and solid products.

Key Operating Parameters

The yield and quality of the final products are dictated by parameters controlled by the reactor system. These include the final temperature, the rate of heating, and the residence time of the material within the reaction zone.

Matching the Feedstock to the Process

The type and quality of plastic waste are the most significant factors influencing the outcome. A reactor's design and operation must account for the specific characteristics of the intended feedstock.

Suitable Plastic Wastes

Pyrolysis is a versatile technology capable of processing various plastic streams. Suitable inputs include post-consumer plastics, segregated municipal solid waste, and even complex materials like multi-layer packaging that are difficult to recycle mechanically.

The Challenge of Feedstock Quality

Plastic waste is rarely pure. Its quality varies significantly based on its source, moisture content, and the presence of non-plastic contaminants like paper, food residue, or dirt.

These variations directly impact the process. For example, high moisture content consumes extra energy to evaporate, and non-plastic materials can increase the amount of low-value solid char produced.

The Problem of Contaminant Plastics

Certain plastics, like polyvinyl chloride (PVC), create significant problems. When heated, PVC releases corrosive hydrochloric acid, which can damage the reactor and downstream equipment. Similarly, polyethylene terephthalate (PET) can also pose challenges, making mixed streams difficult to process without pre-treatment.

Understanding the Trade-offs and Challenges

While pyrolysis is a powerful tool, its practical application involves navigating several key engineering and operational challenges.

Feedstock Variability vs. Output Quality

This is the central trade-off. Using low-cost, highly mixed, and contaminated plastic waste is economically attractive, but it results in lower quality and inconsistent pyrolysis oil. The oil may require significant and costly downstream purification to become a usable product.

Heat Transfer Limitations

Plastics are poor conductors of heat. As they melt inside the reactor, they can form a thick, viscous liquid that is difficult to heat evenly. This can lead to inefficient cracking, lower oil yields, and increased char formation on reactor surfaces.

Operational Complexity

Running a pyrolysis reactor is not a simple "set it and forget it" process. It requires careful management of feedstock feeding systems, removal of char and non-process elements, and handling of the flammable gas stream produced during the reaction.

Making the Right Choice for Your Goal

The optimal approach to plastic pyrolysis depends entirely on your primary objective.

- If your primary focus is producing high-quality, consistent pyrolysis oil: You must invest in robust feedstock sorting and pre-treatment to ensure a clean and uniform input stream.

- If your primary focus is processing highly mixed, low-quality waste: You need a durable, robust reactor design that can handle contaminants and you must accept that the output oil will require significant downstream upgrading.

- If your primary focus is maximizing volume reduction of plastic waste: The exact composition of the outputs is less critical, allowing for a simpler reactor design and less stringent feedstock requirements.

Ultimately, success in plastic pyrolysis is achieved by aligning your feedstock strategy, reactor technology, and end-product goals.

Summary Table:

| Key Factor | Impact on Pyrolysis Process |

|---|---|

| Feedstock Quality | Determines oil purity and process efficiency; contaminants can damage equipment. |

| Reactor Temperature | Controls product yield (e.g., higher temps favor gas production). |

| Residence Time | Affects completeness of plastic breakdown; longer times reduce char. |

| Plastic Type | PVC/PET release corrosive gases; polyolefins (PP/PE) are ideal. |

Ready to transform plastic waste into valuable resources? KINTEK specializes in robust lab equipment and pyrolysis reactors designed to handle diverse plastic feedstocks. Whether you aim to produce high-quality oil or maximize waste volume reduction, our solutions ensure precise temperature control, efficient heat transfer, and operational safety. Contact us today to discuss your project needs and discover how our expertise can optimize your pyrolysis process!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

People Also Ask

- What is the difference between regeneration and reactivation of carbon? Clarifying Key Terminology

- What is pyrolysis of biomass to biofuel? A Complete Guide to Converting Waste into Liquid Fuel

- What is calcination with example? A Guide to Thermal Decomposition Processes

- What is the process of pyrolysis reactor? Turn Waste into Valuable Resources with Thermal Decomposition

- What are the parts of a carbon regeneration kiln? A Guide to Its Core Components and Function

- How long is the calcination process? Optimize Your Process Time for Maximum Efficiency

- What is the temperature of microwave pyrolysis? Achieve Precise Thermal Decomposition

- What is the effect of biochar on microbial population? Build a Thriving Soil Ecosystem with Biochar