Yes, not only can you mill zirconia crowns, it is the primary and most precise method of fabrication. This process relies on computer-aided design and computer-aided manufacturing (CAD/CAM) technology to shape the crown from a solid block of zirconia material, which is then heat-treated to achieve its final, incredible strength.

The critical concept to understand is that zirconia is milled in a soft, chalk-like "green state" or "pre-sintered" state. It is only after the milling is complete that the crown is placed in a special furnace to be sintered, a process that shrinks the material and hardens it into one of the most durable restorations in modern dentistry.

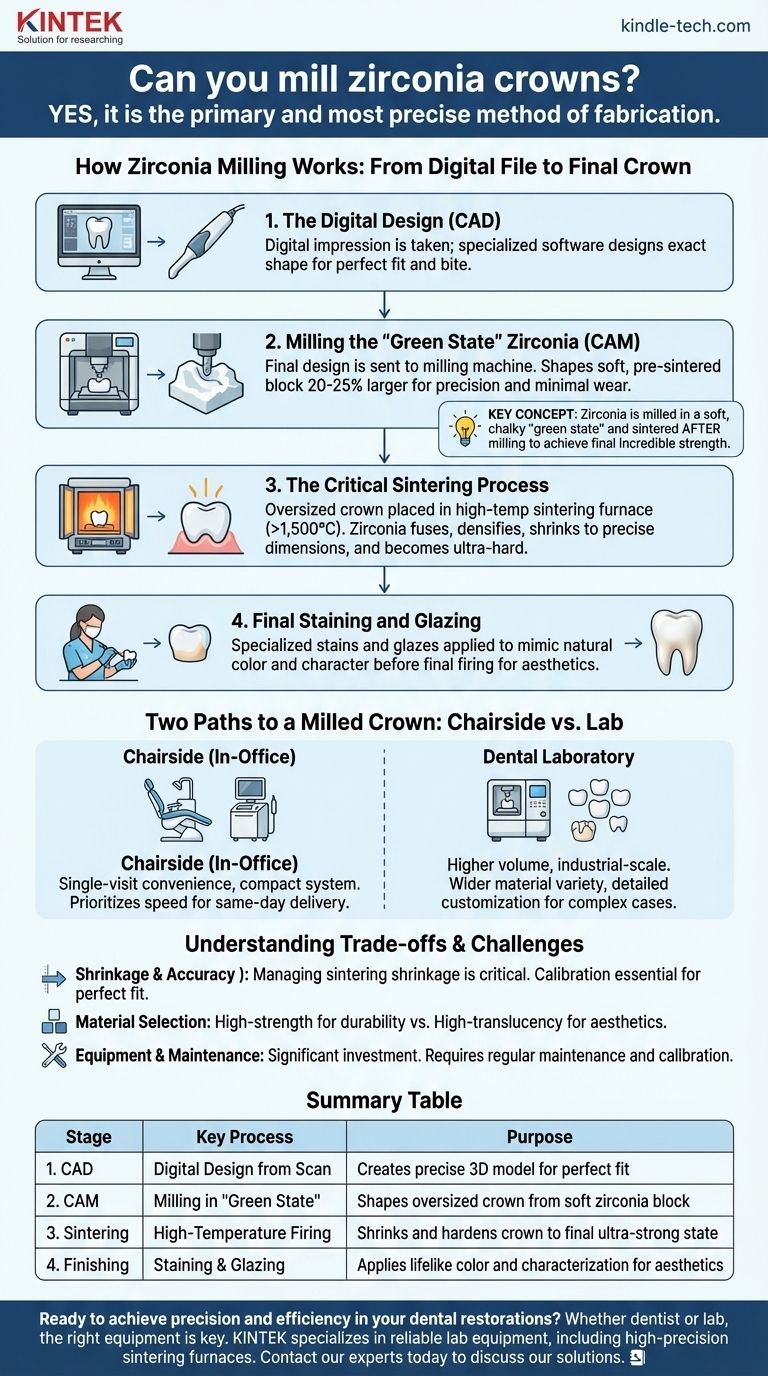

How Zirconia Milling Works: From Digital File to Final Crown

The fabrication of a zirconia crown is a multi-stage process that blends digital precision with material science. Each step is critical to ensuring the final restoration has a perfect fit, proper function, and excellent aesthetics.

Step 1: The Digital Design (CAD)

Before any milling occurs, the crown must exist as a digital file. This is achieved by taking a digital impression of the patient's teeth with an intraoral scanner or by scanning a traditional physical model in a lab.

A technician then uses specialized CAD software to design the crown's exact shape, ensuring it fits the preparation, contacts adjacent teeth correctly, and has the proper bite relationship with the opposing teeth.

Step 2: Milling the "Green State" Zirconia (CAM)

The finalized digital design is sent to a milling machine. The machine carves the crown from a small block or puck of pre-sintered zirconia.

This green state material is soft and slightly chalky, making it easy for the milling burs to shape with high precision and minimal wear. The crown is intentionally milled about 20-25% larger than its final intended size to compensate for the next step.

Step 3: The Critical Sintering Process

After milling, the oversized, fragile crown is carefully removed from the block. It is then placed into a high-temperature sintering furnace.

Over several hours, the furnace heats the zirconia to temperatures often exceeding 1,500°C (2,732°F). This intense heat causes the zirconia particles to fuse and densify, shrinking the crown to its precise, pre-calculated final dimensions and transforming it into an incredibly hard and durable ceramic.

Step 4: Final Staining and Glazing

Once sintered, the crown has its full strength but is typically a monochromatic white. To achieve a natural appearance, a dental technician will apply specialized stains and glazes to mimic the color gradients and character of a real tooth before a final, brief firing in a porcelain oven.

Two Paths to a Milled Crown: Chairside vs. Lab

The technology to mill zirconia is available in two distinct environments, each with its own set of goals and workflows.

Chairside (In-Office) Milling

Systems like Dentsply Sirona's CEREC allow a dentist to design, mill, and deliver a zirconia crown in a single patient visit. The entire workflow—from digital scan to final cementation—happens within the dental office.

This prioritizes speed and patient convenience, leveraging compact milling units and specialized furnaces designed for efficiency.

Dental Laboratory Milling

Dedicated dental labs use larger, more industrial-scale milling machines. These systems can handle a higher volume of work and often offer a wider variety of zirconia materials with different levels of translucency and strength.

Lab-based milling allows technicians to spend more time on detailed characterization and custom aesthetics, making it the preferred choice for complex cosmetic cases or large-scale bridgework.

Understanding the Trade-offs and Challenges

While CAD/CAM milling is a revolutionary technology, it requires a deep understanding of its technical nuances to achieve predictable, high-quality results.

Shrinkage and Accuracy

The single most important variable is managing the sintering shrinkage. The software and milling system must be perfectly calibrated to the specific shrinkage factor of each batch of zirconia blocks. Any error here will result in a crown that does not fit.

Material Selection

Not all zirconia is the same. High-strength zirconia is very opaque and best suited for posterior teeth where durability is paramount. More modern, highly translucent zirconia offers superior aesthetics for anterior teeth but often comes with a slight reduction in flexural strength.

Equipment and Maintenance

CAD/CAM systems represent a significant financial investment. The milling machines require regular maintenance, calibration, and replacement of milling burs to maintain their accuracy over time. Sintering furnaces also require precise calibration to ensure proper material transformation.

How to Apply This to Your Goal

Your decision to use or invest in zirconia milling technology depends entirely on your clinical or business objectives.

- If your primary focus is single-visit convenience: A chairside CAD/CAM system is the definitive solution, allowing you to control the entire process and deliver restorations on the same day.

- If your primary focus is maximum esthetics and material versatility: Partnering with a high-quality dental laboratory that has invested in advanced milling and finishing systems is your best approach.

- If you are a dental lab: Your success hinges on mastering the calibration between your design software and the specific shrinkage rates of your chosen zirconia materials to ensure impeccable accuracy.

Ultimately, milling is the technology that unlocked the full potential of zirconia, transforming it into the go-to material for strong, reliable, and beautiful dental restorations.

Summary Table:

| Stage | Key Process | Purpose |

|---|---|---|

| 1. CAD | Digital Design from Scan | Creates a precise 3D model for a perfect fit |

| 2. CAM | Milling in 'Green State' | Shapes the oversized crown from a soft zirconia block |

| 3. Sintering | High-Temperature Firing | Shrinks and hardens the crown to its final, ultra-strong state |

| 4. Finishing | Staining & Glazing | Applies lifelike color and characterization for aesthetics |

Ready to achieve precision and efficiency in your dental restorations?

Whether you are a dentist looking to bring crown fabrication in-house with a chairside system or a dental lab aiming to perfect your sintering process, the right equipment is key to success. KINTEK specializes in providing reliable lab equipment, including high-precision sintering furnaces essential for transforming milled zirconia into its final, durable state.

Contact our experts today to discuss how our solutions can help you deliver stronger, better-fitting crowns and grow your practice or laboratory.

Visual Guide

Related Products

- Laboratory Four-Body Horizontal Jar Mill

- Disc Cup Vibrating Mill Multi-Platform for Lab

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

People Also Ask

- What is the primary function of a Dental Press Furnace? Fabricate Strong, Aesthetic Dental Restorations

- What are ceramics used for in dentistry? Achieve Natural-Looking, Durable Restorations

- How do electronic controllers function in a furnace for sintering dental materials? The Key to Precision Sintering

- What are dental ceramics made of? A Guide to Composition, Strength, and Aesthetics

- What is the firing temperature of porcelain dental ware? A Guide to Classifications & Cycles

- How long does it take to make zirconia teeth? From Same-Day to 2 Weeks

- What is a dental press used for? Creating High-Strength, Aesthetic Dental Restorations

- What is the effect of zirconia sintering temperature? Master the Key to Strength and Stability