Increasing ball mill efficiency is a process of systematically balancing key operational parameters. The most critical factors to adjust are the mill's rotational speed, the characteristics of the grinding media (its size, material, and volume), and the properties of the material being milled, such as its feed rate and, in wet grinding, its slurry density.

A ball mill is not a brute-force machine; it is a dynamic system governed by physics. True efficiency gains come not from a single "trick," but from understanding the interplay between impact and attrition forces and then methodically tuning each variable to match your specific material and output goals.

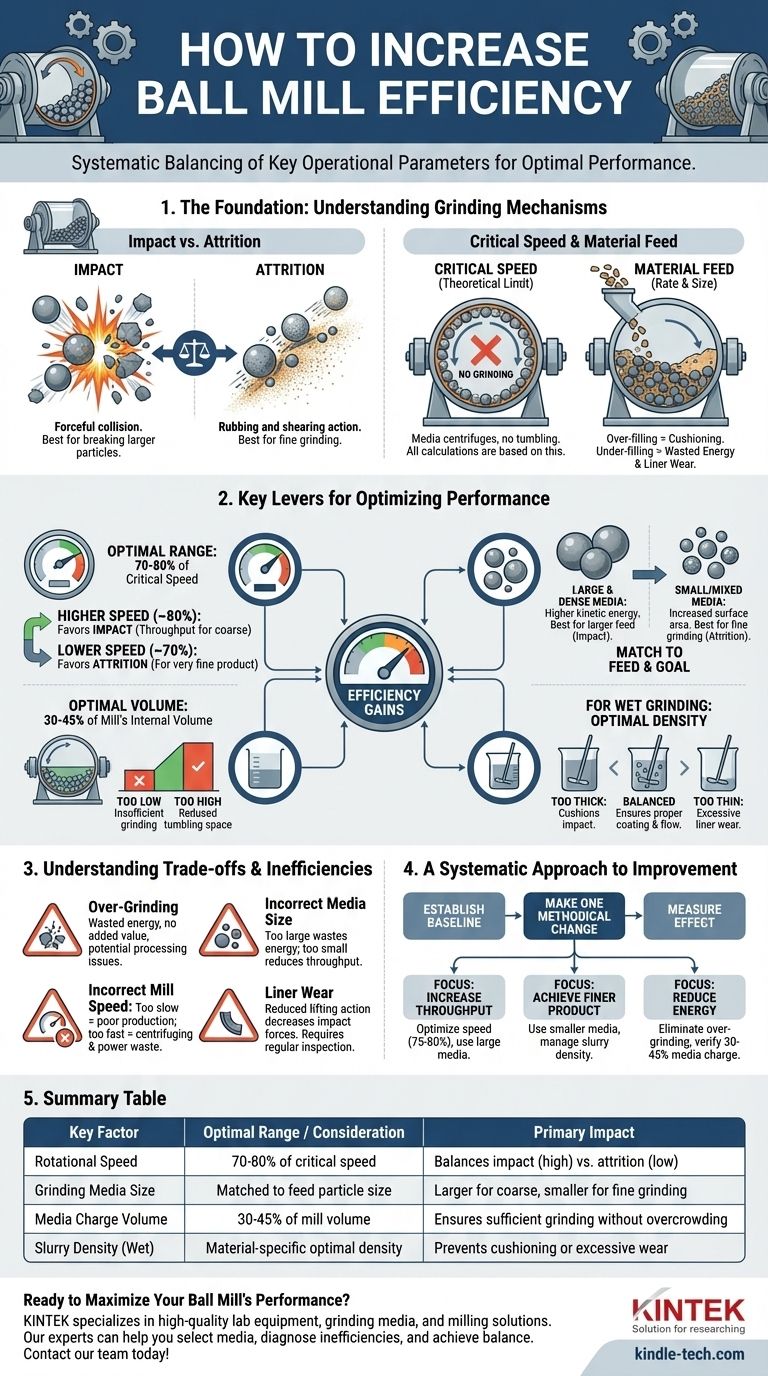

The Foundation: Understanding Grinding Mechanisms

A ball mill's efficiency is determined by how effectively it transfers energy from the rotating shell, through the grinding media, and into the material you want to break down. This happens through two primary mechanisms.

Impact vs. Attrition

Impact is the forceful collision of grinding media (the balls) with the material, which is highly effective for breaking down larger particles. Attrition is the rubbing and shearing action that occurs as balls and particles slide past one another, which is more effective for grinding finer particles. The most efficient grinding often involves a balance of both.

What is "Critical Speed"?

Critical speed is the theoretical rotational speed at which the grinding media would simply be held against the mill's inner wall by centrifugal force, much like clothes in a spin cycle. At this speed, no grinding occurs because the media never tumbles. All operational speed calculations are based on this critical value.

The Role of Material Feed

The rate and size of the material fed into the mill are crucial. Over-filling the mill with material cushions the media, reducing impact forces and lowering efficiency. Conversely, under-filling can lead to wasted energy as the media collides with itself and the mill liners instead of the target material.

Key Levers for Optimizing Performance

To improve your mill's performance, you must focus on the variables you can control. These four levers have the most significant impact on overall efficiency.

Dialing in Rotational Speed

Operating speed is set as a percentage of the critical speed. Speeds between 70-80% of critical speed are common.

- Higher speeds (closer to 80%) favor impact forces, increasing throughput for coarser materials.

- Lower speeds (closer to 70%) favor attrition, which can be better for achieving a very fine final product.

Selecting the Right Grinding Media

The grinding media is the engine of your mill. Its properties must be matched to your feed material and desired product size.

- Media Size: Larger balls are needed to break larger feed particles (impact). A mix of sizes or smaller balls are better for fine grinding (attrition).

- Media Density: Denser media (like steel over ceramic) provides more kinetic energy and impact force, but also requires more power to turn the mill.

Optimizing Media Charge (Volume)

The media charge refers to the volume of the mill occupied by the grinding media. This is typically between 30% and 45% of the mill's internal volume.

- Too low a charge results in insufficient grinding events and wasted energy.

- Too high a charge reduces the space for material and limits the tumbling motion of the media, decreasing efficiency.

Managing Slurry Density (For Wet Grinding)

In wet milling, the slurry density (or pulp density) is critical. The optimal density ensures particles properly coat the media for efficient grinding and flow through the mill correctly. A slurry that is too thick will cushion the media's impact, while one that is too thin will allow for excessive media-on-liner wear.

Understanding the Trade-offs and Inefficiencies

Pursuing one goal, like maximum throughput, can create unintended consequences. Acknowledging these trade-offs is key to balanced, sustainable efficiency.

The Problem of Over-Grinding

Grinding material finer than your target specification is a primary source of wasted energy. It consumes power without adding value to the final product and can even create downstream processing issues.

The Cost of Incorrect Media Size

Using media that is too large for your feed material wastes energy through inefficient impacts. Using media that is too small will not effectively break down the coarsest particles, leading to low throughput and poor product quality.

The Risk of Incorrect Mill Speed

Running the mill too slowly prioritizes attrition, which may be too slow for your production needs. Running it too fast approaches the critical speed, causing the media to centrifuge and stopping the grinding process entirely while still consuming maximum power.

The Impact of Liner Wear

The lifters on the mill's internal liners are essential for tumbling the media. As these liners wear down, their lifting action becomes less effective, reducing impact forces and decreasing overall grinding efficiency. Regular inspection is necessary.

A Systematic Approach to Improving Efficiency

Start by establishing a baseline for your current operation, then make one methodical change at a time to measure its effect.

- If your primary focus is increasing throughput: Prioritize optimizing mill speed towards the higher end of the effective range (e.g., 75-80% of critical) and ensure your media is large enough to break the coarsest feed particles.

- If your primary focus is achieving a finer product: Consider using a smaller top-size media to increase surface area and promote attrition, while carefully managing slurry density to prevent cushioning.

- If your primary focus is reducing energy consumption: Conduct an audit to eliminate over-grinding by adjusting residence time or classifier settings, and verify your media charge is in the optimal 30-45% range.

By treating your ball mill as a precise system of interconnected variables, you can unlock significant and sustainable gains in performance and cost-effectiveness.

Summary Table:

| Key Factor | Optimal Range / Consideration | Primary Impact |

|---|---|---|

| Rotational Speed | 70-80% of critical speed | Balances impact (higher speed) vs. attrition (lower speed) |

| Grinding Media Size | Matched to feed particle size | Larger for coarse grinding, smaller for fine grinding |

| Media Charge Volume | 30-45% of mill volume | Ensures sufficient grinding events without overcrowding |

| Slurry Density (Wet Grinding) | Material-specific optimal density | Prevents cushioning (too thick) or excessive wear (too thin) |

Ready to Maximize Your Ball Mill's Performance?

Optimizing your grinding process is complex, but you don't have to do it alone. KINTEK specializes in high-quality lab equipment and consumables, including grinding media and milling solutions tailored to your specific materials and goals. Our experts can help you:

- Select the perfect grinding media for your application.

- Diagnose inefficiencies and recommend precise adjustments.

- Achieve a balance of high throughput, fine product quality, and lower energy consumption.

Contact our team today for a consultation and let us help you unlock the full potential of your laboratory processes. Get in touch via our contact form to get started!

Visual Guide

Related Products

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Mini Planetary Ball Mill Machine for Laboratory Milling

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

People Also Ask

- What is the primary role of a ball mill in the pretreatment of lignocellulosic biomass? Unlock High Conversion Rates

- How do stainless steel grinding jars and balls contribute to mechanical alloying? Optimize HEA Powder Synthesis

- What are the primary considerations when selecting a Tungsten Carbide Ball Mill? Optimize Your Geochemical Analysis

- What is the function of a planetary ball mill in the preparation of xAl2O3–(1−x)Si3N4? Master Mechanical Activation

- What role does a planetary ball mill play in FeCrAlY-Al2O3 nano-ceramics? Achieve Perfect Mechanical Alloying

- How does a ball mill contribute to optimizing the conductivity of LiFePO4? Unlock High-Performance Battery Materials

- What is the role of a high-energy ball mill in CoCr composite mixing? Unlock Superior Structural Refinement

- What is the primary function of a planetary ball mill in AlN production? Achieve Perfect Material Dispersion