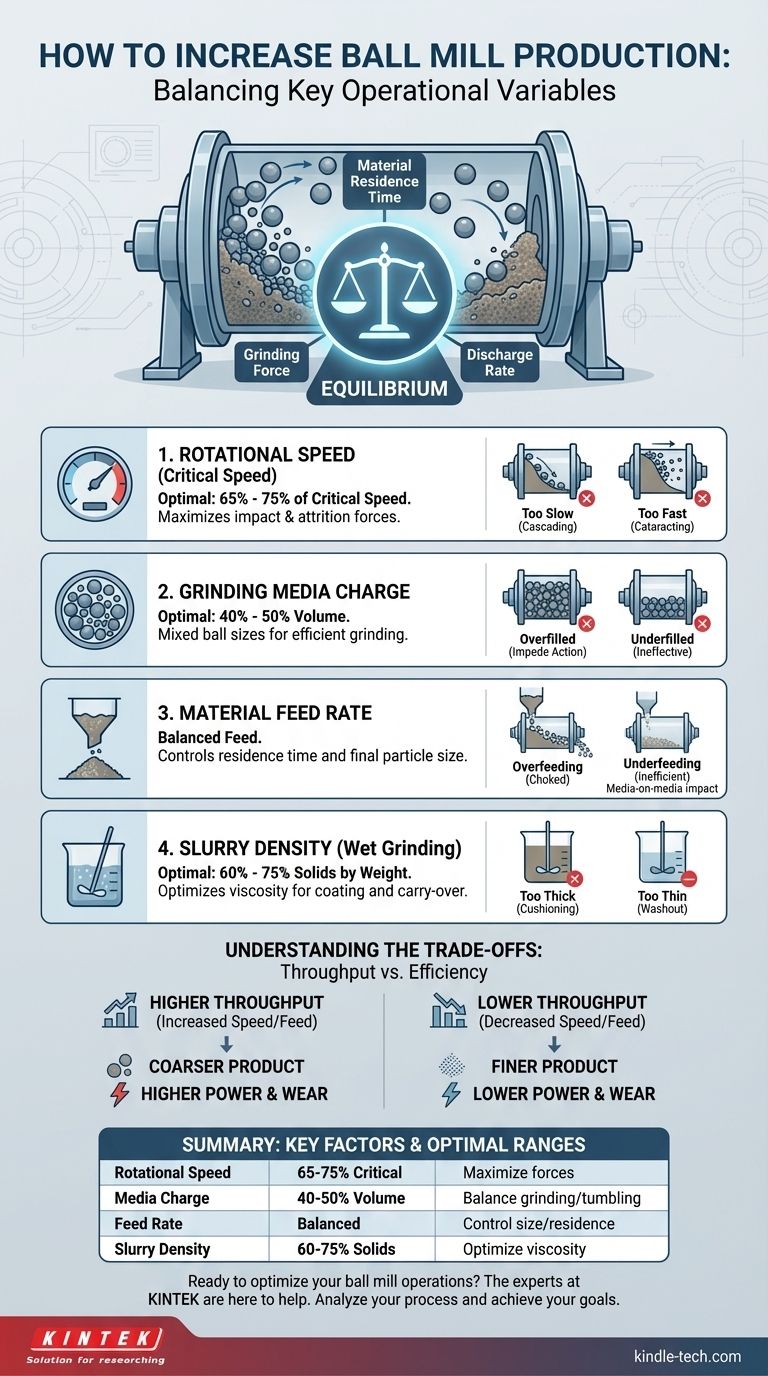

To increase production in a ball mill, you must systematically optimize the interplay between several key operational variables. The most critical factors are the mill's rotational speed, the volume and size of the grinding media (the balls), the material feed rate, and, in wet grinding applications, the slurry density. A change in one parameter requires a corresponding adjustment in the others to achieve higher throughput.

The central challenge in increasing ball mill production is not maximizing a single variable, but finding the precise equilibrium between grinding force, material residence time, and discharge rate. Pushing for more throughput without maintaining this balance will inevitably lead to inefficiency, increased wear, and a failure to meet product specifications.

The Four Pillars of Ball Mill Throughput

Optimizing a ball mill is a process of balancing four interconnected factors. Understanding how each one contributes to the grinding action is the foundation for increasing production effectively.

Optimizing Rotational Speed (Critical Speed)

The speed of the mill dictates how the grinding media behaves. This is measured relative to the "critical speed," the theoretical speed at which the outermost layer of balls would be held against the liner by centrifugal force.

Operating a mill at its critical speed is counterproductive, as no tumbling or grinding occurs. The goal is to find the speed that maximizes the impact and attrition forces.

Most ball mills operate most efficiently between 65% and 75% of their critical speed. Below this range, the balls cascade down, creating more friction but less impact. Above this range, the balls are thrown further, increasing impact but risking inefficient energy transfer and excessive liner wear.

Managing the Grinding Media Charge

The grinding media—the steel or ceramic balls—are the primary tool for particle size reduction. Their characteristics are fundamental to the mill's performance.

The charge volume is the percentage of the mill's internal volume occupied by the balls, typically ranging from 40% to 50%. A lower charge can't grind effectively, while a charge that is too high reduces the space available for the material and can impede proper tumbling action.

Ball size is also critical. Larger balls are used to break down coarse feed material, while smaller balls provide the greater surface area needed for fine grinding. A balanced charge of mixed sizes is often used to achieve efficient grinding across a range of particles.

Regulating the Material Feed Rate

The rate at which you feed new material into the mill directly impacts both production volume and the final particle size.

Overfeeding the mill is a common mistake. It reduces the time each particle spends inside (residence time), leading to a coarse final product. It can also "choke" the mill, cushioning the grinding media and drastically reducing efficiency.

Conversely, underfeeding the mill is inefficient. It wastes energy on over-grinding particles that are already small enough and causes expensive damage as the grinding balls impact each other and the mill liners directly.

Controlling Slurry Density (For Wet Grinding)

In wet grinding operations, the ratio of solids to water, known as slurry or pulp density, is a powerful lever for control.

If the slurry is too thick (too little water), its high viscosity will cushion the balls, reducing the force of their impacts and slowing down the grinding process.

If the slurry is too thin (too much water), material can pass through the mill too quickly without being properly ground, and the slurry may not be viscous enough to effectively coat and carry the grinding media. Most operations find a sweet spot between 60% and 75% solids by weight.

Understanding the Trade-offs: Throughput vs. Efficiency

Attempting to maximize production without acknowledging the inherent trade-offs will lead to poor results and increased costs. True optimization requires a balanced approach.

The Cost of Higher Speed

While increasing speed can increase throughput to a point, it always comes at a cost. Higher speeds dramatically increase power consumption and accelerate the wear on both the mill liners and the grinding media, leading to more frequent and expensive maintenance.

Feed Rate vs. Particle Size

There is an inverse relationship between feed rate and fineness. Pushing more material through the mill will increase your tonnage per hour, but it will almost always result in a coarser final product. You must decide if this coarser grind is acceptable for your downstream processes.

The Limits of Media Charge

Increasing the ball charge might seem like an easy way to add grinding power, but it also increases the mill's weight and the load on the drive motor. Exceeding the motor's capacity can lead to shutdowns, while an overly full mill leaves little room for the material to be ground effectively.

Making the Right Adjustments for Your Goal

Your optimization strategy should be guided by your primary objective. Use these principles as a starting point for methodical, one-at-a-time adjustments.

- If your primary focus is maximizing raw tonnage: Focus on increasing the feed rate while adjusting mill speed and slurry density to handle the load, but be prepared for a slightly coarser final product.

- If your primary focus is achieving a specific particle size: Prioritize controlling the feed rate and slurry density to ensure sufficient residence time, even if it means operating at a slightly lower throughput.

- If your primary focus is reducing operational costs: Operate the mill at the lower end of its optimal speed range (e.g., 65-70% of critical speed) and ensure the media charge and feed rate are perfectly balanced to avoid wasted energy.

True production gains come from methodical testing and finding the unique equilibrium for your specific material and machinery.

Summary Table:

| Key Factor | Optimal Range | Impact on Production |

|---|---|---|

| Rotational Speed | 65% - 75% of critical speed | Maximizes impact & attrition forces for efficient grinding. |

| Grinding Media Charge | 40% - 50% of mill volume | Balances grinding power with space for material tumbling. |

| Material Feed Rate | Balanced to avoid over/under-feeding | Controls residence time and final particle size. |

| Slurry Density (Wet) | 60% - 75% solids by weight | Optimizes viscosity for effective grinding media coating and material carry-over. |

Ready to optimize your ball mill operations and boost your production efficiency? The experts at KINTEK are here to help. We specialize in providing high-quality laboratory equipment and consumables, including grinding media and milling solutions tailored to your specific needs. Our team can help you analyze your process and recommend the right setup to achieve your goals for throughput, particle size, and cost reduction. Contact KINTEL today to discuss how we can support your laboratory's success!

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Four-Body Horizontal Jar Mill

- Laboratory Single Horizontal Jar Mill

- Laboratory Horizontal Planetary Ball Mill Milling Machine

People Also Ask

- What is the difference between a ball mill and a sag mill? A Guide to Primary vs. Secondary Grinding

- Why is a laboratory ball mill used in Co-Ni catalyst research? Optimize CO2 Conversion with Precise Milling

- What role does a planetary ball mill play in eggshell fertilizer production? Unlock Superior Chemical Reactivity

- What are the disadvantages of a ball mill? High Energy Use, Noise, and Contamination Risks

- What is the purpose of ball milling? A Versatile Tool for Material Synthesis and Modification