Proper planetary mixer maintenance is a non-negotiable routine that extends beyond simple cleaning. It involves a systematic schedule of daily inspections for cleanliness and damage, periodic checks of lubrication and critical components like drive belts, and annual professional servicing. Following this discipline is the single most important factor in ensuring your machine's longevity and reliability.

The goal of mixer maintenance is not merely to keep it clean, but to shift from a reactive "fix-it-when-it-breaks" mindset to a proactive strategy. This systematic approach protects your investment, ensures operational safety, and prevents the catastrophic cost of unexpected downtime.

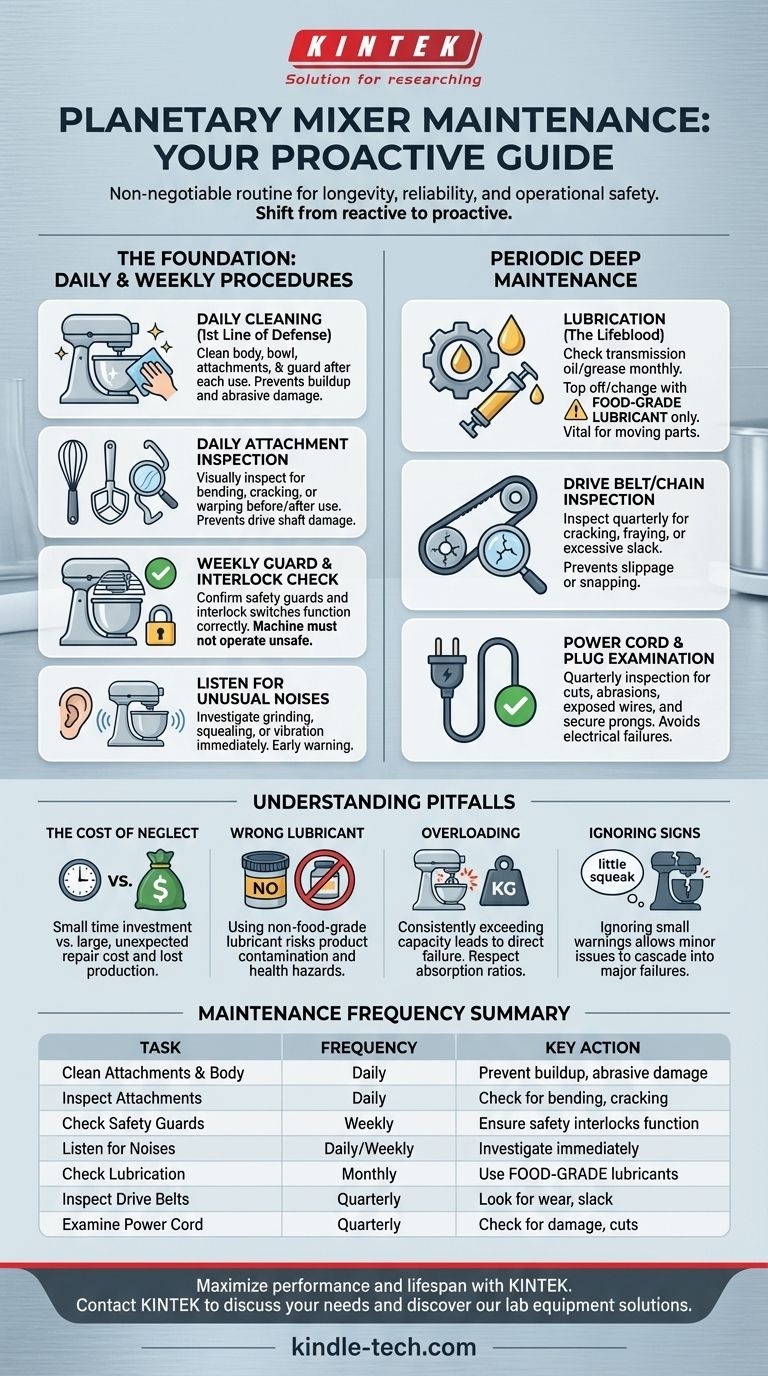

The Foundation: Daily and Weekly Procedures

These simple, consistent actions form the bedrock of a reliable maintenance program. They take only a few minutes but prevent the vast majority of common failures.

Daily Cleaning: The First Line of Defense

After each use, thoroughly clean the mixer's body, bowl, attachments, and bowl guard. This is not just for food safety and hygiene; it prevents dried product from hardening and migrating into seals or moving parts, which can cause significant abrasive damage over time.

Daily Inspection of Attachments

Before and after use, visually inspect the whisk, paddle, and dough hook. Look for any signs of bending, cracking, or warping. A bent attachment can strike the bowl, leading to damage to both the attachment and the mixer's drive shaft.

Weekly Inspection of Guards and Interlocks

Safety guards and magnetic interlock switches are critical safety features. Once a week, confirm that the mixer will not operate if the bowl is lowered or if the bowl guard is not in its proper place. A faulty interlock is a severe safety hazard.

Checking for Unusual Noises or Vibrations

You are the person most familiar with your machine's normal operating sounds. Any new grinding, squealing, or excessive vibration is an early warning sign. Investigate it immediately, as it often indicates a lubrication issue or a failing component.

Periodic Deep Maintenance

These tasks should be performed on a monthly or quarterly basis, depending on your mixer's usage intensity.

Lubrication: The Lifeblood of Your Mixer

Many mixers have a transmission oil level that can be viewed through a sight glass. Check this monthly and top it off or change it according to the manufacturer's specifications. Always use the recommended food-grade lubricant.

For mixers with grease points, apply the specified food-grade grease to ensure smooth operation of bowl lifts and other moving parts. Insufficient lubrication is a primary cause of premature gear and bearing failure.

Inspecting Drive Belts or Chains

If your mixer is belt-driven, inspect the belts for signs of cracking, fraying, or excessive slack. A loose belt will slip under load, reducing performance, while a worn belt can snap unexpectedly, causing immediate and complete downtime.

Examining the Power Cord and Plug

The power cord is a common point of failure due to constant movement and kitchen stress. Inspect the entire length of the cord for cuts, abrasions, or exposed wires. Check that the plug's prongs are straight and secure.

Understanding the Trade-offs and Common Pitfalls

Objectively understanding the risks and common mistakes is crucial for protecting your equipment.

The Cost of Neglect vs. The Cost of Maintenance

The primary trade-off is clear: a small, consistent investment of time versus a large, unexpected expense. A few minutes of daily maintenance can prevent a multi-thousand-dollar transmission repair and days of lost production.

Using the Wrong Lubricant

Using a standard industrial grease instead of a certified food-grade lubricant is a critical error. In the event of a seal failure, non-food-grade oil or grease can contaminate your product, leading to waste and potential health risks.

Overloading the Machine

Consistently exceeding your mixer's capacity is a direct path to failure. Understand your mixer's "absorption ratio" (the ratio of water to flour) and never push it beyond the manufacturer's stated limits for heavy doughs. This is not a maintenance task, but a common operational error that no amount of maintenance can overcome.

Ignoring Small Warning Signs

That "little squeak" or "minor vibration" is the machine telling you something is wrong. Ignoring these signs allows a small, easily fixable problem (like a dry bearing) to cascade into a major, expensive failure (like a seized transmission).

Creating Your Maintenance Schedule

Your ideal maintenance frequency depends on your operational intensity. Use these guidelines to establish a reliable routine.

- If you are a low-volume bakery or restaurant: A focus on rigorous daily cleaning combined with a thorough monthly check of lubrication and belts is a strong foundation.

- If you run a high-volume commercial kitchen or food production line: Implement a documented daily checklist for operators and schedule quarterly deep maintenance and annual professional servicing without fail.

- If you just acquired a used mixer: Assume it has a deferred maintenance backlog. Perform a complete fluid change, belt inspection, and safety-check verification before putting it into regular service.

A well-maintained mixer is a reliable and profitable partner in your production process.

Summary Table:

| Maintenance Task | Frequency | Key Action |

|---|---|---|

| Clean Attachments & Body | Daily | Prevent product buildup and abrasive damage |

| Inspect Attachments | Daily | Check for bending, cracking, or warping |

| Check Safety Guards & Interlocks | Weekly | Ensure machine will not operate if safety features are engaged |

| Listen for Unusual Noises | Daily/Weekly | Investigate grinding, squealing, or vibrations immediately |

| Check Lubrication (Oil/Grease) | Monthly | Use only manufacturer-recommended food-grade lubricants |

| Inspect Drive Belts | Quarterly | Look for cracking, fraying, or excessive slack |

| Examine Power Cord & Plug | Quarterly | Check for cuts, abrasions, or exposed wires |

Maximize the performance and lifespan of your lab or kitchen equipment with KINTEK.

Just as a proactive maintenance schedule is vital for your planetary mixer, using the right high-quality equipment and consumables from the start is equally important. KINTEK specializes in supplying reliable lab equipment and consumables that are built to last, helping you avoid unexpected downtime and ensure consistent results.

Let our experts help you equip your laboratory for success. Contact KINTEK today to discuss your specific needs and discover how our solutions can support your operations.

Visual Guide

Related Products

- Laboratory Oscillating Orbital Shaker

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Laboratory Single Horizontal Jar Mill

- High Shear Homogenizer for Pharmaceutical and Cosmetic Applications

- Platinum Sheet Electrode for Laboratory and Industrial Applications

People Also Ask

- What role does a laboratory orbital shaker play in silane coupling? Enhance Self-Assembled Monolayer Uniformity

- Why is a high-precision orbital shaker required for chitin adsorption? Achieve Rapid Equilibrium & Precise Data

- What is the primary purpose of using an orbital shaker during metal ion adsorption? Optimize PAF Performance

- What is the role of a laboratory shaker in PHA research? Accelerate Extremophile Screening & Bioplastic Development

- What are the primary functions of a laboratory orbital shaker during BMP testing? Maximize Methane Yield Accuracy