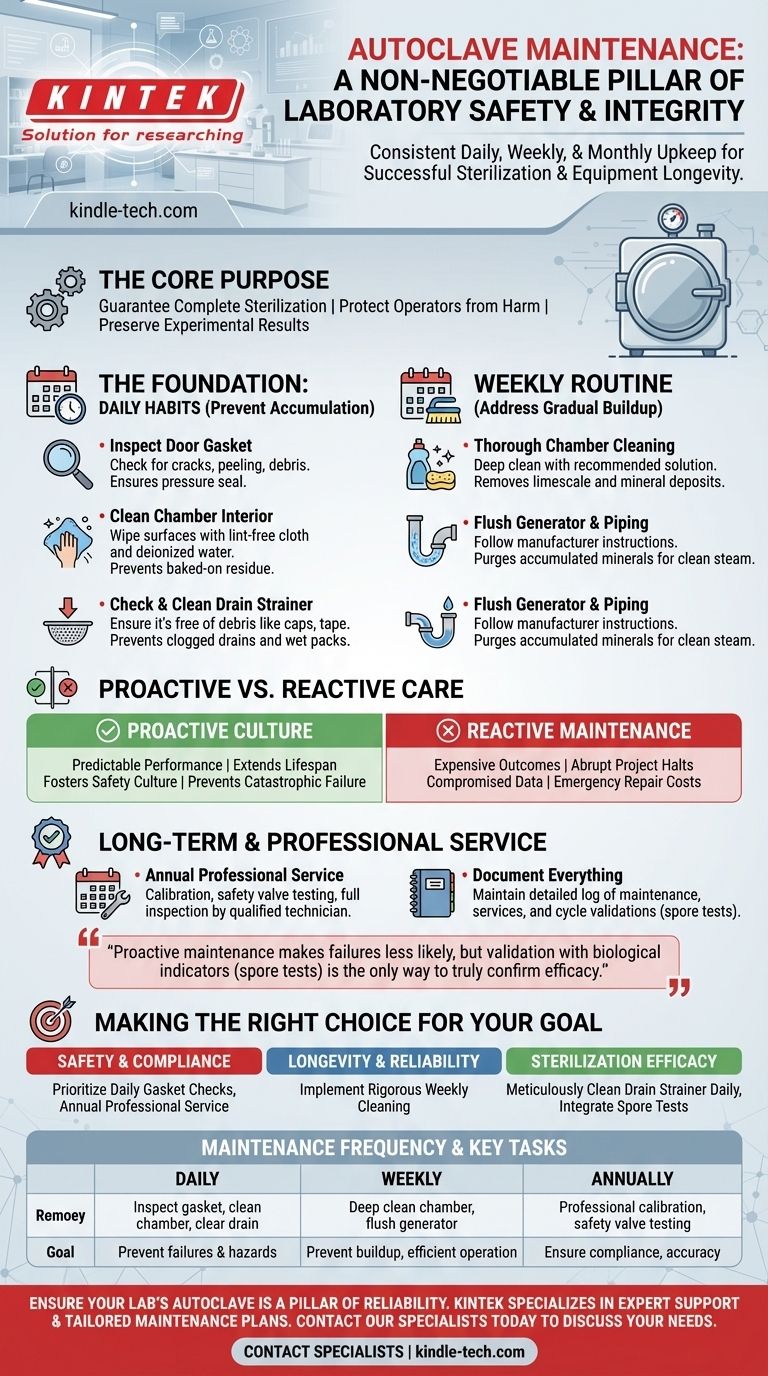

Effective autoclave maintenance is a non-negotiable pillar of laboratory safety and data integrity. Proper upkeep involves a consistent schedule of daily, weekly, and monthly tasks that focus on cleaning the chamber and drains, inspecting critical components like the door gasket, and ensuring regular professional calibration and service. This routine is essential for ensuring every sterilization cycle is successful and the equipment operates safely.

The core purpose of autoclave maintenance extends beyond simply preventing breakdowns. It is a systematic process to guarantee that every cycle achieves complete sterilization, protects operators from harm, and preserves the validity of your experimental results.

The Foundation: Daily Checks and Cleaning

The most frequent failures and safety issues arise from the neglect of simple, daily habits. These checks take only a few minutes but provide the greatest return on investment for equipment longevity and reliability.

Why Daily Habits Matter

Consistent daily inspection and cleaning prevent the accumulation of minor residues and debris that can lead to clogged drains, poor steam penetration, and failed cycles. This proactive approach is the first line of defense against unscheduled downtime.

Inspect the Door Gasket

Before the first cycle of the day, visually inspect the silicone door gasket for any signs of cracking, peeling, or debris. The gasket creates the pressure seal; a compromised seal is one of the most common causes of cycle failure and can pose a significant safety risk.

Clean the Chamber Interior

After the final cycle, wipe down the interior surfaces of the chamber with a lint-free cloth and deionized water. Spills from media or solutions, if left unchecked, can bake onto the surface, leading to corrosion and potentially compromising future sterilization loads.

Check and Clean the Chamber Drain Strainer

This is a critical step. Locate the drain strainer at the bottom of the chamber and ensure it is completely free of debris like loosened cap fragments, tape, or agar. A clogged drain prevents proper steam evacuation and can lead to wet packs and incomplete sterilization.

Establishing a Weekly Routine

Weekly tasks are more thorough and address the gradual buildup that daily wipe-downs may not catch. This routine is vital for maintaining the internal plumbing and overall performance of the unit.

The Purpose of a Weekly Schedule

A weekly schedule addresses the slow accumulation of mineral deposits and other contaminants within the system. These tasks ensure that water and steam can flow freely, which is essential for efficient heat transfer and proper sterilization.

Thorough Chamber Cleaning

Clean the chamber more deeply using a recommended autoclave cleaning solution or a mild detergent. This process, often followed by a rinse cycle, removes scale and mineral deposits (limescale) that can insulate surfaces and reduce heating efficiency.

Flush the Generator and Piping

If your autoclave has a steam generator, follow the manufacturer's instructions for a weekly flush. This process purges accumulated minerals and sediment from the generator, preventing clogs and ensuring a consistent supply of clean steam for every cycle.

Understanding the Trade-offs: Proactive vs. Reactive Care

Every lab must decide between a proactive maintenance culture and a reactive one. The consequences of this choice directly impact budgets, timelines, and safety.

The True Cost of Neglect

Reactive maintenance—fixing the autoclave only when it fails—inevitably leads to more expensive outcomes. It results in abrupt project halts, potentially compromised data from failed runs, and emergency repair costs that far exceed the price of routine upkeep.

The Benefit of a Proactive Culture

A documented, proactive maintenance schedule provides predictable and reliable performance. It extends the functional lifespan of the autoclave, reduces the likelihood of catastrophic failure, and fosters a stronger culture of safety and accountability within the laboratory.

The Most Common Pitfall

A common mistake is assuming that because a cycle completes without an error code, sterilization was successful. Sterilization failures are often invisible. Proactive maintenance makes these failures less likely, but validation with biological indicators (spore tests) is the only way to truly confirm efficacy.

Long-Term and Professional Servicing

While daily and weekly tasks can be performed by lab personnel, certain critical functions must be handled by certified professionals to ensure safety and compliance.

The Role of Annual Professional Service

An autoclave is a high-pressure vessel and is subject to strict safety regulations. A qualified technician must perform an annual service that includes calibration of temperature and pressure sensors, testing of safety valves, and a thorough inspection of all critical components.

Document Everything

Maintain a detailed logbook for your autoclave. Record every maintenance task, service call, and cycle validation test (e.g., spore tests). This documentation is essential for troubleshooting, demonstrating compliance during audits, and tracking the equipment's performance over time.

Making the Right Choice for Your Goal

Your maintenance protocol should be directly aligned with your laboratory's highest priorities.

- If your primary focus is safety and compliance: Prioritize daily gasket checks, confirming the function of safety relief valves, and scheduling mandatory annual professional servicing without fail.

- If your primary focus is equipment longevity and reliability: Implement a rigorous weekly cleaning schedule to prevent the mineral buildup and corrosion that cause most premature component failures.

- If your primary focus is ensuring sterilization efficacy: Meticulously clean the chamber drain strainer daily and integrate regular biological indicator (spore test) validation into your routine.

A well-maintained autoclave is the silent, reliable partner in your laboratory's success.

Summary Table:

| Maintenance Frequency | Key Tasks | Primary Goal |

|---|---|---|

| Daily | Inspect door gasket, clean chamber interior, clear drain strainer | Prevent cycle failures and safety hazards |

| Weekly | Deep clean chamber, flush steam generator and piping | Prevent mineral buildup and ensure efficient operation |

| Annually | Professional calibration, safety valve testing, full inspection | Ensure compliance, safety, and sensor accuracy |

Ensure your lab's autoclave is a pillar of reliability, not a point of failure. Proper maintenance is non-negotiable for safety and valid results. KINTEK specializes in laboratory equipment and consumables, offering expert support to keep your autoclave—and your entire lab—running smoothly and safely. Contact our specialists today to discuss a maintenance plan tailored to your lab's needs.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Test Sieves and Sieving Machines

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- What are the advantages of using an autoclave equipped with a stirring device for molten salt testing? Dynamic Accuracy

- What experimental conditions do stainless steel autoclaves provide for PCT-A leaching? Optimize Phosphate Glass Testing

- What are the standard operating parameters for an autoclave? Master Temperature, Pressure, and Time for Sterilization

- What is the necessity of using an autoclave for pre-treating culture media? Ensure Accurate Ag2O/TiO2 Testing

- What is the primary function of a laboratory autoclave in the pre-treatment of medical plastic waste for liquid fuel?