In short, you test a metal’s quality by subjecting it to a series of standardized tests that measure its specific mechanical and chemical properties. The most fundamental of these are the tensile test (to measure strength and ductility), the hardness test (to measure wear resistance), and chemical analysis (to confirm its composition). The "quality" of a metal is not a single score but its proven ability to meet the demands of a specific application.

The central concept to grasp is that "quality" in metals is context-dependent. The goal of testing is not to find the "best" metal, but to verify that a specific metal has the right properties—such as strength, hardness, or corrosion resistance—to perform safely and effectively for its intended purpose.

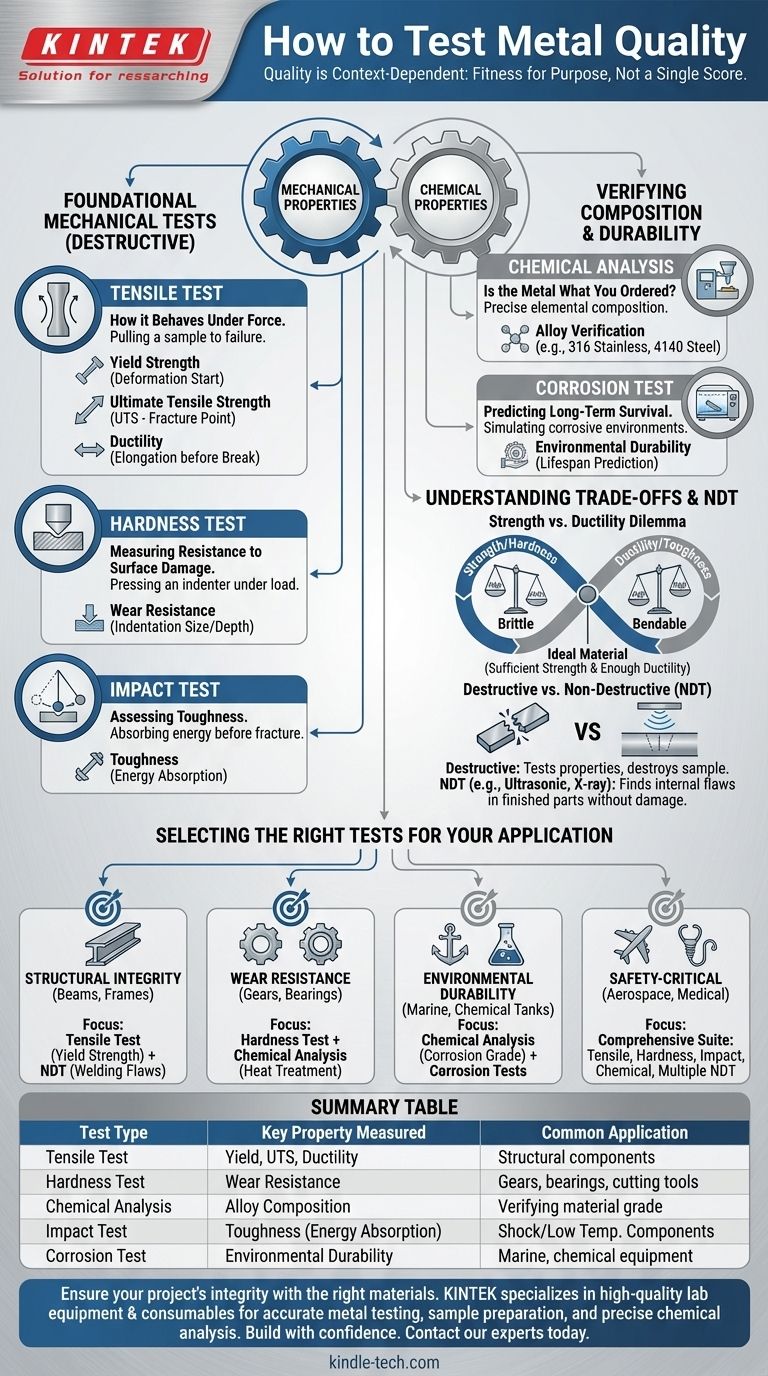

What Does "Metal Quality" Truly Mean?

Before choosing a test, you must first define what "quality" means for your project. The properties that make a metal high-quality for a bridge beam are entirely different from those required for a surgical implant or a high-speed cutting tool.

It's About Fitness for Purpose

A metal's quality is a measure of its "fitness for purpose." This is determined by verifying its specific, measurable properties against an established engineering standard or design requirement.

A test doesn't just pass or fail a metal; it provides data. That data is then compared to the required specification for the application.

The Two Pillars: Mechanical and Chemical Properties

All metal properties fall into two main categories, and testing is designed to quantify them.

- Mechanical Properties: This is how the material behaves when physical forces are applied. It includes strength, hardness, ductility (the ability to deform without breaking), and toughness (the ability to absorb energy before fracturing).

- Chemical Properties: This refers to the metal's elemental makeup and its ability to resist its environment. This primarily involves alloy composition and corrosion resistance.

Foundational Mechanical Tests: How the Metal Behaves Under Force

These tests are typically destructive, meaning the sample being tested is destroyed in the process. They are performed on representative coupons of material from the same batch as the final product.

The Tensile Test: The Cornerstone of Material Data

The tensile test is the most common and informative mechanical test. A standardized sample of the metal is pulled from both ends until it breaks.

This single test reveals three critical properties:

- Yield Strength: The amount of stress the metal can withstand before it starts to permanently deform. This is often the most critical number for structural design.

- Ultimate Tensile Strength (UTS): The maximum stress the metal can endure before it starts to fracture.

- Ductility: How much the metal can stretch or elongate before it breaks. This is a measure of its ability to bend or deform without failing, which is crucial for preventing catastrophic, brittle failure.

The Hardness Test: Measuring Resistance to Surface Damage

Hardness is a metal's ability to resist localized plastic deformation, such as a scratch or an indentation. In a hardness test (e.g., Rockwell, Brinell, or Vickers), a hardened indenter is pressed into the metal's surface under a specific load.

The size or depth of the resulting indentation gives a hardness value. This property is a primary indicator of wear resistance and is critical for components like gears, bearings, and cutting tools.

The Impact Test: Assessing Toughness

Toughness is different from strength. It is a metal's ability to absorb energy and deform before it fractures. A brittle material, like glass, is strong but not tough.

In an impact test (e.g., Charpy or Izod), a weighted pendulum is swung at a notched specimen of the metal. The amount of energy the specimen absorbs during fracture is measured. This is crucial for applications that may experience sudden loads or shocks, especially at low temperatures where some metals can become brittle.

Verifying Composition and Durability

Mechanical properties are a direct result of a metal's chemical makeup and microstructure. These tests confirm the material is what it claims to be and can survive its intended environment.

Chemical Analysis: Is the Metal What You Ordered?

This is the most fundamental quality check. Using techniques like Optical Emission Spectrometry (OES) or X-ray Fluorescence (XRF), a lab can precisely determine the elemental composition of the material.

This analysis verifies that the alloy matches a specific grade (e.g., 316 Stainless Steel or 4140 Alloy Steel). An incorrect composition can lead to drastic and unexpected changes in mechanical properties and corrosion resistance.

Corrosion Testing: Predicting Long-Term Survival

For metals exposed to moisture, chemicals, or salt-laden air, corrosion resistance is a primary measure of quality and lifespan.

Tests like the salt spray test involve placing the metal in a chamber that simulates a highly corrosive environment for an extended period. This helps predict how the material will hold up over years of service in applications like marine hardware or chemical processing equipment.

Understanding the Trade-offs

Selecting a metal and its testing protocol always involves balancing competing properties. Understanding these trade-offs is the mark of a seasoned professional.

The Strength vs. Ductility Dilemma

Almost universally, as you increase a metal's strength and hardness (often through heat treatment or work hardening), you decrease its ductility and toughness. A very hard metal is often very brittle. The ideal material for a given application is one that provides sufficient strength while retaining enough ductility to avoid sudden, brittle failure.

Destructive vs. Non-Destructive Testing (NDT)

The tests described above (tensile, impact) are destructive. For finished parts, you often need to check for internal flaws without destroying the component.

This is done with Non-Destructive Testing (NDT) methods like ultrasonic, radiographic (X-ray), or magnetic particle inspection. These methods don't measure mechanical properties but are essential for finding hidden defects like cracks or voids that could cause a part to fail in service.

Selecting the Right Tests for Your Application

Use your end goal to guide your testing strategy. A Certificate of Test or Material Test Report (MTR) from a supplier should provide data for the properties you require.

- If your primary focus is structural integrity (beams, frames, pressure vessels): Demand tensile test results to verify yield strength and NDT to check for welding flaws.

- If your primary focus is wear resistance (gears, bearings, cutting surfaces): Prioritize hardness testing and confirm the alloy's chemical composition is correct for the intended heat treatment.

- If your primary focus is environmental durability (marine parts, chemical tanks): Insist on chemical analysis to verify the correct corrosion-resistant grade and, for critical uses, review data from corrosion tests.

- If your primary focus is safety-critical components (aerospace, medical): A comprehensive suite of tests is required, including tensile, hardness, impact, chemical analysis, and multiple forms of NDT on finished parts.

By aligning the right tests with your specific performance needs, you can select materials with confidence and ensure the long-term integrity and safety of your project.

Summary Table:

| Test Type | Key Property Measured | Common Application |

|---|---|---|

| Tensile Test | Yield Strength, Ultimate Tensile Strength, Ductility | Structural components (beams, frames) |

| Hardness Test | Wear Resistance | Gears, bearings, cutting tools |

| Chemical Analysis | Alloy Composition | Verifying material grade (e.g., 316 Stainless Steel) |

| Impact Test | Toughness (Energy Absorption) | Components subject to shock or low temperatures |

| Corrosion Test | Environmental Durability | Marine hardware, chemical processing equipment |

Ensure your project's integrity with the right materials.

KINTEK specializes in providing high-quality lab equipment and consumables essential for accurate metal testing—from sample preparation for tensile and hardness tests to supplies for precise chemical analysis. Our expertise supports laboratories in verifying material properties and ensuring compliance with industry standards.

Let us help you build with confidence. Contact our experts today to discuss your specific laboratory needs and how our solutions can enhance your material verification process.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- How flammable is biochar? A Guide to Understanding and Managing Its Fire Risk

- What affects melting point chemistry? A Guide to Molecular Forces and Lattice Energy

- How does biomass compare to fossil fuels? A Clear Breakdown of Carbon Impact & Energy Use

- How many types of hardening processes are commonly used? Choose Between Through-Hardening and Case Hardening

- What gas emissions come from pyrolysis? Turning Waste into Energy and Carbon Sequestration

- How does a benchtop incubator shaker ensure consistency during AHP pretreatment? Achieve Uniform Biomass Degradation

- What is the process of pyrolysis in the lab? A Step-by-Step Guide to Controlled Thermal Decomposition

- Does pyrolysis emit CO2? Unpacking the Carbon Footprint of Waste-to-Energy