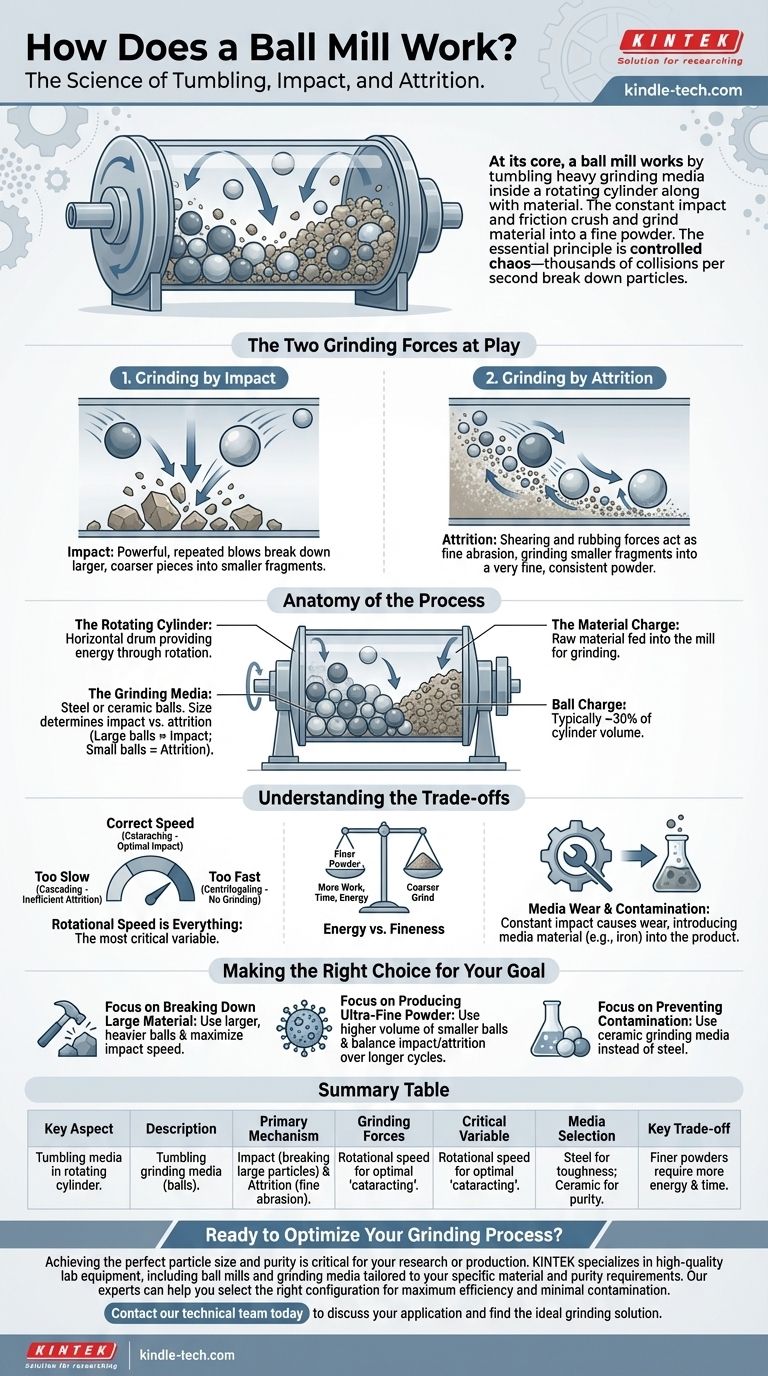

At its core, a ball mill works by tumbling heavy grinding media, typically steel or ceramic balls, inside a rotating cylinder along with the material you need to grind. As the cylinder spins, the balls are lifted up the side and then cascade down, crushing and grinding the material through constant impact and friction. This simple, powerful mechanism is highly effective at reducing coarse materials into a fine powder.

The essential principle is controlled chaos. A ball mill harnesses the force of gravity and motion, causing thousands of collisions per second. These collisions—both powerful impacts and grinding attrition—systematically break down particles until a desired fineness is achieved.

The Two Grinding Forces at Play

A ball mill's effectiveness comes from two distinct but complementary actions happening simultaneously inside the cylinder. Understanding these two forces is key to understanding the entire process.

Grinding by Impact

As the mill rotates, the grinding balls are carried partway up the wall of the cylinder. Once they reach a certain height, they detach and fall, crashing down onto the material below. This action is called impact.

These powerful, repeated blows are primarily responsible for breaking down larger, coarser pieces of the feed material into smaller fragments.

Grinding by Attrition

As the balls tumble over one another, they also rub and slide against each other and the material being ground. This shearing and rubbing force is known as attrition.

Attrition is less about brute force and more about fine abrasion. This action is what grinds the smaller fragments into a very fine, consistent powder.

Anatomy of the Process

To control the outcome, you must understand the key components and how they interact. The entire system is a balance between the machine, the media, and the material itself.

The Rotating Cylinder

This is the main body of the mill, a horizontal or slightly inclined drum that holds both the media and the material. Its rotation provides all the energy for the grinding process.

The Grinding Media

These are the balls (or sometimes rods) that do the actual work. They are typically made of high-carbon steel or ceramic.

The size of the balls is critical. Large balls provide greater impact for breaking coarse feed, while smaller balls create more contact points and are better for fine grinding through attrition.

The volume the balls occupy is called the ball charge, which is typically around 30% of the cylinder's volume.

The Material Charge

This is the raw material fed into the mill to be ground. The efficiency of the grind depends on the ratio of grinding media to the material charge.

Understanding the Trade-offs

While powerful, the ball milling process involves critical considerations and is not a one-size-fits-all solution. Objectively weighing these factors is essential for any application.

Rotational Speed is Everything

The speed of the cylinder's rotation is the most critical operational variable.

- Too slow, and the balls will simply slide or "cascade," resulting in inefficient grinding dominated by attrition.

- Too fast, and centrifugal force will pin the balls to the cylinder wall, preventing them from falling and stopping the grinding action entirely.

- The correct speed creates a "cataracting" motion, where balls are carried almost to the top before falling, maximizing the force of impact.

Energy vs. Fineness

Achieving a finer powder requires more work. Grinding a material to a very small particle size can take exponentially more time and energy than a coarser grind.

Media Wear and Contamination

The constant impact and attrition cause the grinding balls and the mill's inner lining to wear down over time. This wear can introduce small amounts of the media's material (e.g., iron from steel balls) into the final product, which can be a critical issue in high-purity applications like ceramics or pharmaceuticals.

Making the Right Choice for Your Goal

The setup of a ball mill must be tuned to its specific purpose. By adjusting the key variables, you can optimize the process for different outcomes.

- If your primary focus is breaking down large, coarse material: Use larger, heavier grinding balls and a rotational speed that maximizes impact forces.

- If your primary focus is producing an ultra-fine powder: Use a higher volume of smaller balls to increase surface area and a speed that balances impact with attrition over a longer grinding cycle.

- If your primary focus is preventing product contamination: Use ceramic grinding media instead of steel to ensure the purity of the final powder.

Ultimately, the ball mill's enduring utility lies in its simple design and versatile, powerful grinding action.

Summary Table:

| Key Aspect | Description |

|---|---|

| Primary Mechanism | Tumbling grinding media (balls) inside a rotating cylinder. |

| Grinding Forces | Impact (breaking large particles) and Attrition (fine abrasion). |

| Critical Variable | Rotational speed for optimal 'cataracting' ball motion. |

| Media Selection | Steel for toughness; Ceramic for purity-sensitive applications. |

| Key Trade-off | Finer powders require more energy and longer grinding times. |

Ready to Optimize Your Grinding Process?

Achieving the perfect particle size and purity is critical for your research or production. KINTEK specializes in high-quality lab equipment, including ball mills and grinding media tailored to your specific material and purity requirements. Our experts can help you select the right configuration for maximum efficiency and minimal contamination.

Contact our technical team today to discuss your application and find the ideal grinding solution for your laboratory.

Visual Guide

Related Products

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- Why are cell disruption systems required for harvesting intracellular nanoparticles? Unlock Your Bio-Synthetic Potential

- What is the impact of speed on ball mill performance? Optimize Grinding Efficiency & Particle Size

- What role does a ball mill play in the preparation of Ti-Si-C reaction powder mixtures? Unlock SHS Efficiency

- What is the primary role of grinding equipment in the pretreatment of copper concentrate for bioleaching?

- What are the disadvantages of bead milling? Managing Contamination, Heat, and Process Complexity

- What is the mechanism of action of a colloid mill? Master High-Shear Processing for Superior Emulsions and Dispersions

- What is the role of an industrial dry grinder in the surface modification of 304L stainless steel? Expert Insights

- What are the problems with ball mills? High Energy Use, Noise, and Component Wear Explained