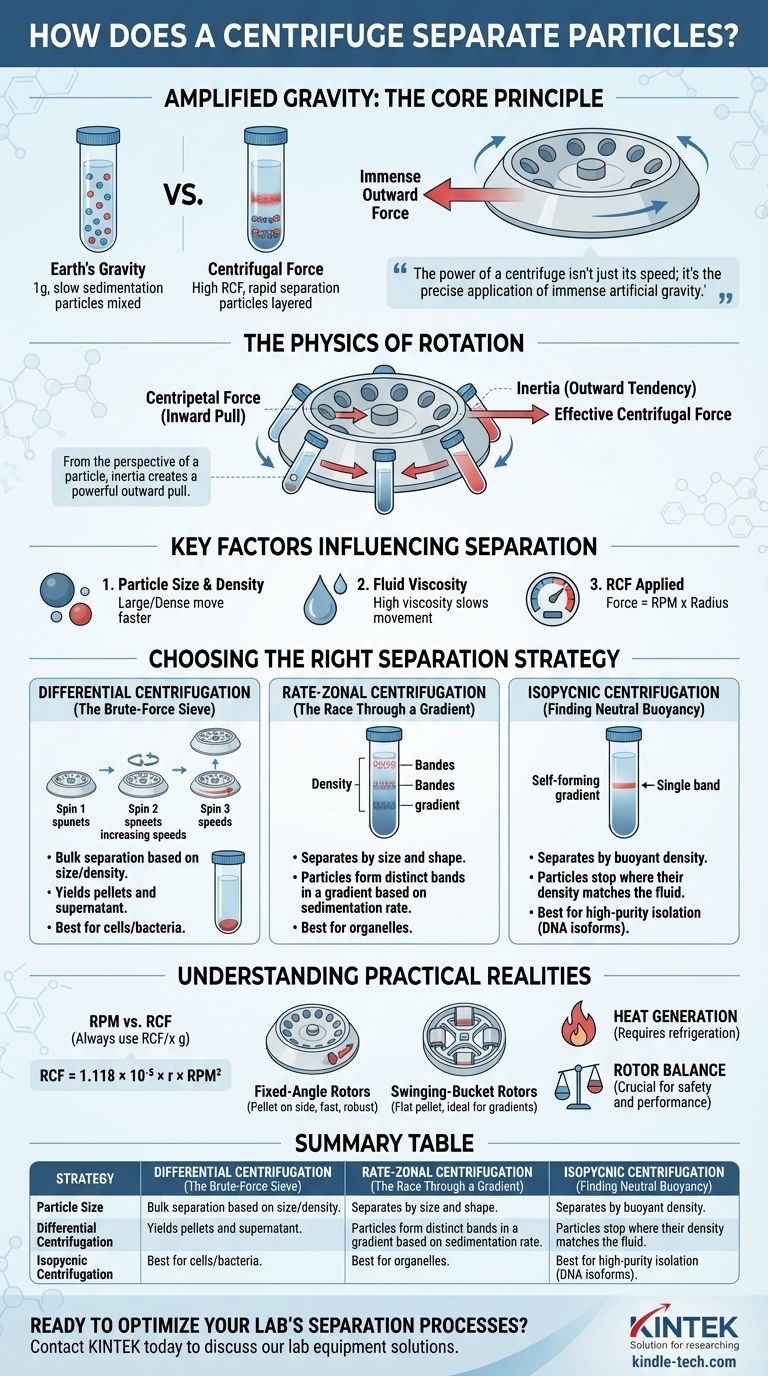

At its core, a centrifuge is an instrument of amplified gravity. It uses the physics of rapid rotation to generate an immense outward force, separating components within a liquid mixture far more effectively than Earth's gravity ever could. This process, known as centrifugation, sorts particles based on their fundamental properties like density, size, and shape, causing denser or larger materials to move outward and separate from lighter, smaller ones.

The power of a centrifuge isn't just its speed; it's the precise application of immense artificial gravity. By understanding and controlling this force, you can separate microscopic components that would otherwise remain mixed, turning a process that could take days or years into a matter of minutes.

The Fundamental Principle: Amplifying Sedimentation

To truly grasp how a centrifuge works, you must first understand the process it accelerates: sedimentation.

From Gravity to G-Force

Sedimentation is the natural tendency for particles suspended in a liquid to settle out of the fluid in response to a force, most commonly gravity. A fine sand mixed in water will eventually settle to the bottom, forming a distinct layer.

A centrifuge replaces the relatively weak pull of gravity with a much stronger simulated gravitational field, known as Relative Centrifugal Force (RCF), often measured in "g's" (multiples of Earth's gravity).

The Physics of Rotation

When a rotor spins, the tubes and their contents are constantly forced to change direction to travel in a circle. This requires a centripetal force pulling them toward the center.

From the perspective of a particle inside the spinning tube, its own inertia—its tendency to continue in a straight line—creates a powerful outward pull. This is the effective centrifugal force. This force is what drives the separation.

Key Factors Influencing Separation

The speed at which a particle moves outward (its sedimentation rate) is determined by a few key variables:

- Particle Size and Density: Larger and denser particles have more mass and are acted upon more strongly by the centrifugal force, causing them to sediment much faster than smaller, less-dense particles.

- Fluid Viscosity: The "thickness" of the liquid medium creates drag. A more viscous fluid will slow down the movement of all particles, requiring longer spin times or higher speeds.

- RCF Applied: The force itself is a product of both the rotational speed (RPM) and the radius of the rotor. Doubling the speed quadruples the force.

Choosing the Right Separation Strategy

Not all centrifugation is the same. The method you choose depends entirely on what you are trying to accomplish, ranging from crude separation to ultra-pure isolation.

Differential Centrifugation: The Brute-Force Sieve

This is the most common and straightforward method. The sample is subjected to a series of spins at progressively higher speeds.

After each spin, the settled material (pellet) is separated from the remaining liquid (supernatant). The supernatant is then spun again at a higher speed to pellet the next-smallest set of particles. It's effective for bulk separation (like pelleting cells from culture media) but yields relatively impure fractions.

Rate-Zonal Centrifugation: The Race Through a Gradient

This method separates particles primarily by size and shape. The sample is carefully layered on top of a pre-formed density gradient (e.g., a sucrose solution that is more concentrated at the bottom).

When spun, particles travel through the gradient in distinct bands based on their size. Larger particles move faster. The run is stopped before any particle reaches the bottom, effectively separating components into zones based on their sedimentation rate.

Isopycnic Centrifugation: Finding Neutral Buoyancy

This is the ultimate technique for separating particles based on their buoyant density. The sample is often mixed with a gradient-forming solution (like cesium chloride).

During a long, high-speed spin, the particles travel through the self-forming gradient until they reach a point where their own density perfectly matches the density of the surrounding liquid. At this "isopycnic point," they stop moving, creating highly purified, high-resolution bands.

Understanding the Trade-offs and Practical Realities

Mastering centrifugation requires understanding its practical limitations and the equipment itself.

RPM vs. RCF: The Most Common Point of Confusion

RPM (Revolutions Per Minute) measures how fast the rotor is spinning. However, the actual separating force (RCF) also depends on the rotor's radius. A small rotor at 10,000 RPM generates far less force than a large rotor at the same speed.

For this reason, scientific protocols always specify RCF (or "x g"), not RPM. This ensures results are reproducible across different machines.

Fixed-Angle vs. Swinging-Bucket Rotors

- Fixed-Angle Rotors hold tubes at a static angle. They are more robust, can achieve higher speeds, and are efficient for pelleting. The downside is that the pellet is smeared along the side of the tube.

- Swinging-Bucket Rotors have hinges that allow the tubes to swing out to a horizontal position during the run. This is ideal for density gradients, as the bands form cleanly and the pellet is flat at the bottom of the tube.

The Hidden Variable: Heat

High-speed centrifugation generates significant heat from air friction, which can damage or denature biological samples like proteins and nucleic acids. For sensitive applications, a refrigerated centrifuge is essential to maintain a stable, cool temperature.

The Non-Negotiable: Rotor Balance

Centrifuges must be perfectly balanced. Tubes placed opposite each other in the rotor must have identical weights. An imbalanced rotor spinning at high speed creates immense vibration that can destroy the instrument and pose a serious safety hazard.

Making the Right Choice for Your Goal

Your application dictates the correct centrifugation strategy.

- If your primary focus is rapid, bulk separation (e.g., pelleting cells or bacteria): Differential centrifugation is the fast, efficient choice.

- If your primary focus is separating particles of similar density but different sizes (e.g., purifying organelles like mitochondria and lysosomes): Rate-zonal centrifugation provides the necessary resolution.

- If your primary focus is achieving the highest possible purity based on density (e.g., separating plasmid DNA isoforms): Isopycnic centrifugation is the gold standard.

By understanding these core principles, you move from simply operating a machine to strategically directing a powerful separation tool.

Summary Table:

| Centrifugation Method | Primary Separation Principle | Best For |

|---|---|---|

| Differential | Size & Density | Bulk separation, pelleting cells |

| Rate-Zonal | Size & Shape | Separating organelles, similar density particles |

| Isopycnic | Buoyant Density | High-purity isolation (e.g., DNA isoforms) |

Ready to Optimize Your Lab's Separation Processes?

Understanding the principles of centrifugation is the first step. Choosing the right equipment is what ensures your research succeeds. At KINTEK, we specialize in providing high-performance laboratory centrifuges and consumables tailored to your specific separation needs—whether you're working with sensitive biological samples or require ultra-pure isolations.

Our experts can help you select the perfect centrifuge and rotor configuration to achieve precise, reproducible results every time.

Contact KINTEK today to discuss how our lab equipment solutions can enhance your workflow and drive your research forward.

Visual Guide

Related Products

- Three-dimensional electromagnetic sieving instrument

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- What is the purpose of connecting a cold trap at the reactor outlet? Protect Equipment and Analyze Liquid Products

- What machine is used for pyrolysis? Choose the Right Reactor for Your Feedstock and Goals

- What is the strength of the magnetron magnetic field? It's About Function, Not Just Force

- What is gold sputtering for SEM? Prevent Charging and Enhance Image Quality for Non-Conductive Samples

- How does a constant temperature shaker contribute to the accuracy of antibiotic degradation? Precision Lab Results

- How do activators function in SHS coating? Master Gas-Phase Transport for Rapid Coating Deposition

- Is a filter press better than a clarifier? Choose the Right Tool for Your Separation Goal

- What are the primary process conditions for TiC-reinforced Cu-Sn-Ni gradient composites? Achieve 1200°C Precision