At its core, a plasma incinerator works by using an intense electrical arc to superheat a gas into a plasma state. This plasma, often hotter than the surface of the sun, is then used to break down waste materials not by burning, but by tearing their molecules apart into basic elements.

The crucial distinction is that plasma gasification is not traditional incineration. Instead of combustion with oxygen, it uses extreme heat in a controlled environment to convert waste into a usable synthetic gas (syngas) and an inert, glass-like solid (slag).

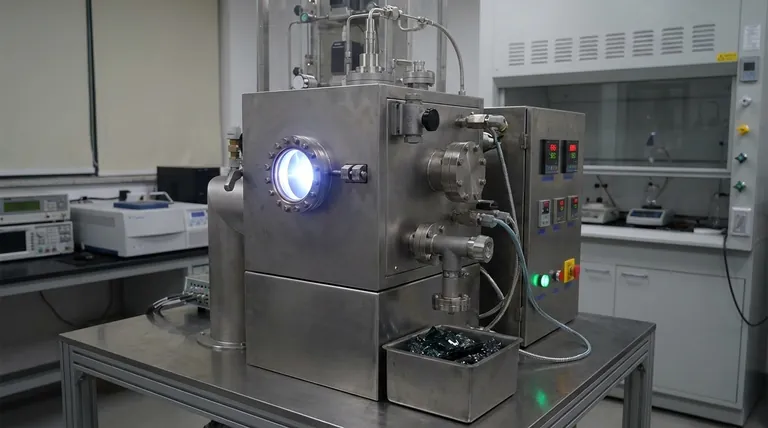

The Core Mechanism: From Electricity to Plasma

The process begins with the creation of the plasma itself, which acts as the destructive agent. This happens in a device often called a plasma torch or gasifier.

Creating the Plasma Arc

A very high-voltage electrical current is passed between two electrodes. This current jumps the gap between them, creating a sustained, high-energy electrical arc, similar to a continuous bolt of lightning.

Superheating the Inert Gas

An inert gas, such as argon or nitrogen, is then forced under pressure through this powerful electrical arc. The arc's immense energy instantly superheats the gas to extreme temperatures.

Achieving the Plasma State

This superheating process strips electrons from the gas atoms, creating an ionized gas known as plasma—the fourth state of matter. This plasma can reach temperatures of several thousand degrees Celsius.

What Happens Inside the Converter

Once created, the plasma is channeled from the torch into a sealed chamber, known as a converter, which contains the waste material.

Molecular Dissociation, Not Combustion

The intense thermal energy of the plasma does not "burn" the waste in the conventional sense. Instead, it causes molecular dissociation, breaking down complex organic materials into their simplest constituent atoms and molecules.

The Two Primary Outputs: Syngas and Slag

This process results in two main byproducts. The organic portion of the waste is converted into a synthetic gas (syngas), which is primarily composed of hydrogen and carbon monoxide and can be used as a fuel.

The inorganic materials, such as metals, glass, and silica, melt and fuse together. As they cool, they form a stable, non-leaching, glass-like substance called vitrified slag, which is safe for use in construction or for disposal in a landfill.

Understanding the Trade-offs

While powerful, plasma gasification is a specialized technology with significant operational considerations. Its application is a matter of balancing its unique capabilities against its high costs.

The Advantage: Complete Destruction

The primary benefit is its ability to handle nearly any type of waste, including highly hazardous materials like medical waste or chemical sludges. The process completely destroys harmful organic compounds, preventing the formation of toxic dioxins and furans common in lower-temperature incineration.

The Challenge: High Energy Consumption

Creating and sustaining a plasma arc is an incredibly energy-intensive process. The electrical demand is the single largest operational cost and can sometimes result in a negative net energy balance, even after accounting for the energy produced from the syngas.

The Challenge: Capital Cost and Complexity

Plasma gasification facilities are complex and expensive to build and maintain. They require highly skilled personnel to operate safely and efficiently, making them a significant investment compared to traditional waste management methods.

Making the Right Choice for Your Goal

Plasma gasification is a powerful tool, but its suitability depends entirely on the specific waste stream and the primary objective.

- If your primary focus is destroying hazardous waste: This technology is one of the most effective and definitive solutions for rendering dangerous materials inert and safe.

- If your primary focus is reducing landfill volume: It offers an unparalleled reduction in waste volume, converting mixed solid waste into a small fraction of its original size in the form of inert slag.

- If your primary focus is energy generation: The high electrical input often makes it less efficient as a primary power source compared to other waste-to-energy technologies, unless dealing with very specific, high-energy waste streams.

Ultimately, plasma gasification should be viewed as a specialized solution for the most challenging waste problems, where its high cost is justified by its unique destructive capability.

Summary Table:

| Key Feature | Description |

|---|---|

| Core Process | Uses an electrical arc to create a superheated plasma that dissociates waste molecules. |

| Primary Outputs | Produces synthetic gas (syngas) for energy and a stable, glass-like slag. |

| Key Advantage | Completely destroys hazardous materials and reduces waste volume dramatically. |

| Main Challenge | High energy consumption and significant capital investment required. |

Ready to explore advanced waste management solutions for your laboratory?

At KINTEK, we specialize in providing cutting-edge lab equipment and consumables. If you are dealing with complex waste streams, including hazardous materials, our expertise can help you identify the most efficient and effective treatment technologies.

Let's discuss how our solutions can enhance your lab's safety and sustainability. Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- Do diamond testing machines work? Choose the Right Tester for Accurate Results

- What is the impregnation method of catalyst preparation? Achieve High Dispersion & Activity

- What are the benefits of metallurgy? Achieve Superior Material Performance and Efficiency

- What is the process of plasma sputtering? A Guide to Precision Thin Film Deposition

- What role does a laboratory high-precision oven play in bioreactor stability? Ensure High-Pressure Accuracy

- What is the use of sputter coater? For High-Quality Thin Film Deposition & SEM Sample Prep

- What are the components of a pyrolysis reactor? A Guide to Core Parts & Designs

- Why must a forced air drying oven be used for fluorosilicone rubber post-curing? Ensure Peak Material Performance