At its core, a pressure reactor is a specialized, sealed vessel designed to safely contain chemical reactions under pressures significantly higher than the surrounding atmosphere. This controlled high-pressure environment is the key to its function, and it is achieved in one of two ways: either the pressure builds up naturally from the reaction itself (autogenous pressure), or it is intentionally added from an external source, like a cylinder of compressed gas.

The crucial insight is that a pressure reactor is not just a container; it's a tool for manipulating the fundamental conditions of a chemical reaction. By controlling pressure, you can increase reaction rates, force liquids to stay in their liquid state well above their normal boiling points, and achieve chemical transformations that are impossible under normal atmospheric conditions.

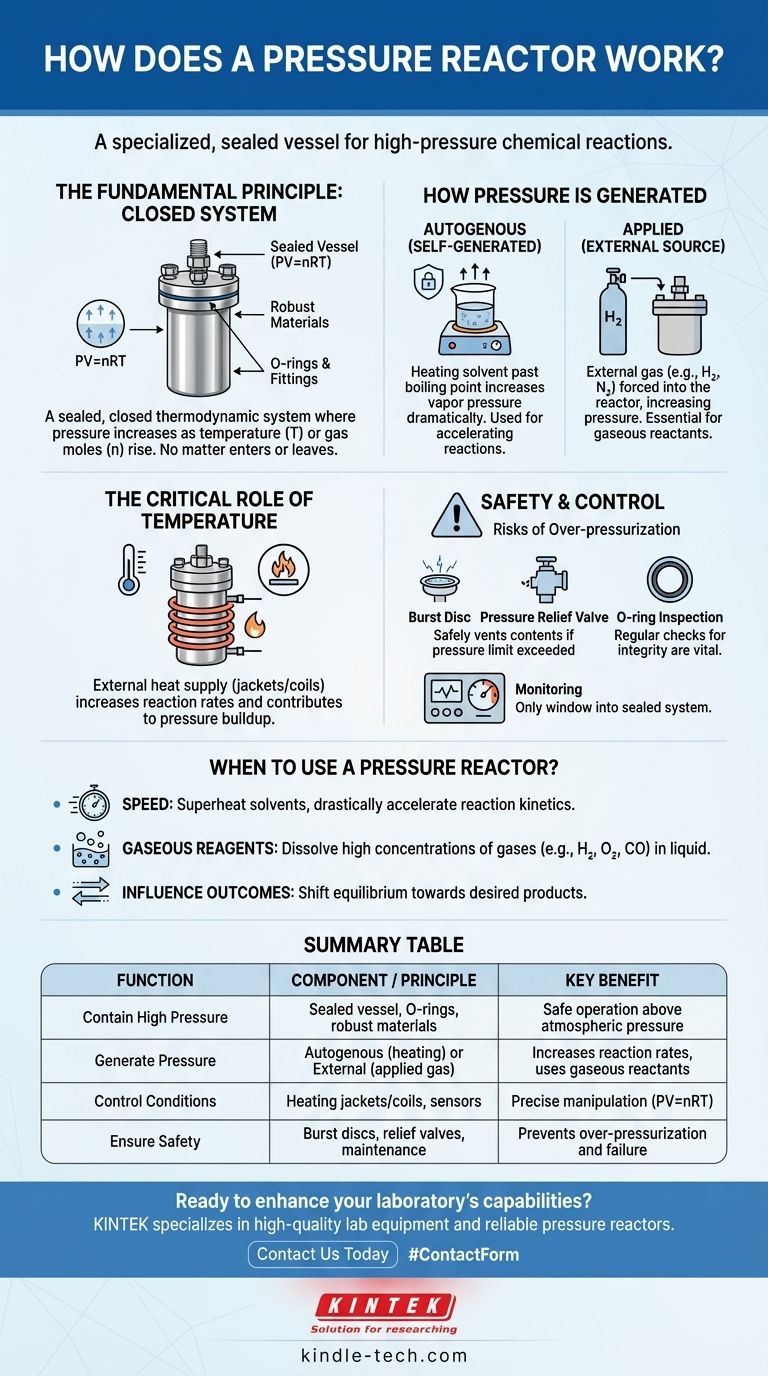

The Fundamental Principle: A Closed Thermodynamic System

A pressure reactor operates as a closed system, meaning no matter can enter or leave once the reaction begins. This principle is the foundation of how it works.

Creating a Sealed Environment

The vessel, often made of robust materials like stainless steel, is sealed with a head that contains fittings for monitoring and control. Gaskets or O-rings create a tight seal, ensuring that as pressure builds, nothing can leak out.

The Ideal Gas Law in Action

The behavior inside the reactor is governed by basic thermodynamic principles, best described by the Ideal Gas Law (PV=nRT). In a sealed vessel with a fixed volume (V), increasing the temperature (T) or the number of moles of gas (n) from the reaction will inevitably cause the pressure (P) to rise. The reactor is engineered to safely contain this increase.

How Pressure is Generated and Controlled

The method used to generate pressure dictates how the reactor is used and what types of reactions it can facilitate.

Autogenous Pressure (Self-Generated)

The simplest way pressure builds is by heating the contents. When a solvent is heated above its atmospheric boiling point in a sealed vessel, it cannot boil away. Instead, its vapor pressure increases dramatically, pressurizing the system. This technique is often used to accelerate reactions that are slow at lower temperatures.

Applied Pressure (External Source)

For many reactions, a specific gas is a required reactant. In processes like catalytic hydrogenation, a high pressure of hydrogen gas is forced into the reactor from an external cylinder. This increases the concentration of dissolved hydrogen in the reaction liquid, dramatically speeding up the reaction rate. An inert gas like nitrogen can also be used to create a high-pressure environment without participating in the reaction.

The Critical Role of Temperature

Nearly all pressure reactions involve an external heat supply. Heating jackets or internal coils raise the temperature of the reactants. This not only increases the reaction rate directly but also contributes significantly to the pressure buildup, as explained by the gas laws.

Understanding the Trade-offs and Safety Imperatives

The power of a pressure reactor comes with significant responsibilities and risks. Operating at high pressure requires meticulous attention to safety and equipment integrity.

The Risk of Over-pressurization

The primary danger is a runaway reaction that generates pressure faster than the vessel can handle, potentially leading to a catastrophic failure. Modern reactors are equipped with safety features like burst discs or pressure relief valves that will safely vent the contents if a set pressure limit is exceeded.

Material Integrity and Maintenance

The vessel, seals, and fittings are under constant stress. It is critical to regularly inspect for any signs of corrosion, wear, or damage, particularly to O-rings and fittings on the vessel head, which can cause dangerous leaks. Keeping up-to-date service records is a non-negotiable part of safe operation.

Challenges in Reaction Monitoring

Because the system is a sealed, opaque metal container, you cannot visually inspect the reaction. This makes you entirely dependent on reliable instruments to monitor internal temperature and pressure, which are your only windows into what is happening inside.

When Is a Pressure Reactor the Right Tool?

Choosing to use a pressure reactor is a deliberate decision based on the specific goals of your chemical process.

- If your primary focus is speed: Use a pressure reactor to superheat solvents past their normal boiling points, drastically accelerating reaction kinetics.

- If your primary focus is using gaseous reagents: Use a pressure reactor to dissolve high concentrations of gases like hydrogen, oxygen, or carbon monoxide into a liquid phase for reactions.

- If your primary focus is influencing reaction outcomes: Use a pressure reactor to shift a chemical equilibrium toward the desired products, especially in reactions where the products occupy less volume than the reactants.

Ultimately, a pressure reactor gives you direct control over one of the most powerful variables in chemistry, enabling you to drive reactions toward your desired outcome with precision.

Summary Table:

| Function | Key Component / Principle | Key Benefit |

|---|---|---|

| Contain High Pressure | Sealed vessel with O-rings, robust materials (e.g., stainless steel) | Enables safe operation above atmospheric pressure |

| Generate Pressure | Autogenous (self-generated by heating) or External (applied gas) | Increases reaction rates and allows use of gaseous reactants |

| Control Conditions | Heating jackets/coils, pressure/temperature sensors | Precise manipulation of reaction environment (PV=nRT) |

| Ensure Safety | Burst discs, pressure relief valves, regular maintenance | Prevents over-pressurization and catastrophic failure |

Ready to enhance your laboratory's capabilities with precise high-pressure control?

KINTEK specializes in high-quality lab equipment, including reliable pressure reactors designed for safety and performance. Whether your work involves catalytic hydrogenation, accelerated synthesis, or other demanding processes, our reactors provide the robust, controlled environment you need.

Contact us today using the form below to discuss your specific application and discover how KINTEK's solutions can drive your research forward.

Visual Guide

Related Products

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- Laboratory High Pressure Horizontal Autoclave Steam Sterilizer for Lab Use

People Also Ask

- How does a vacuum reactor facilitate the hydrophobic modification of catalyst supports? Maximize Biodiesel Efficiency

- What is the role of a high-pressure hydrothermal reactor in the preparation of POMs@ZIF-67 precursors?

- Why must nitrogen de-aeration be performed in a reactor before CO2 corrosion tests? Ensure Valid Testing Data

- What core functions do high-pressure reactors perform in biomass steam explosion? Unlock Lignocellulosic Potential

- What is the primary function of a high-pressure reactor in APTES-modified TiO2 prep? Enhance Synthesis Efficiency

- What role do chemical reactors or elution equipment play in the regeneration of Ni(II) adsorbents? Unlock Resource Recovery

- What are the advantages of stainless steel reactors? Superior Durability and Purity for Demanding Processes

- What is the purpose of using anaerobic batch reactors in food wastewater? Optimize Methane Yield and BMP Testing