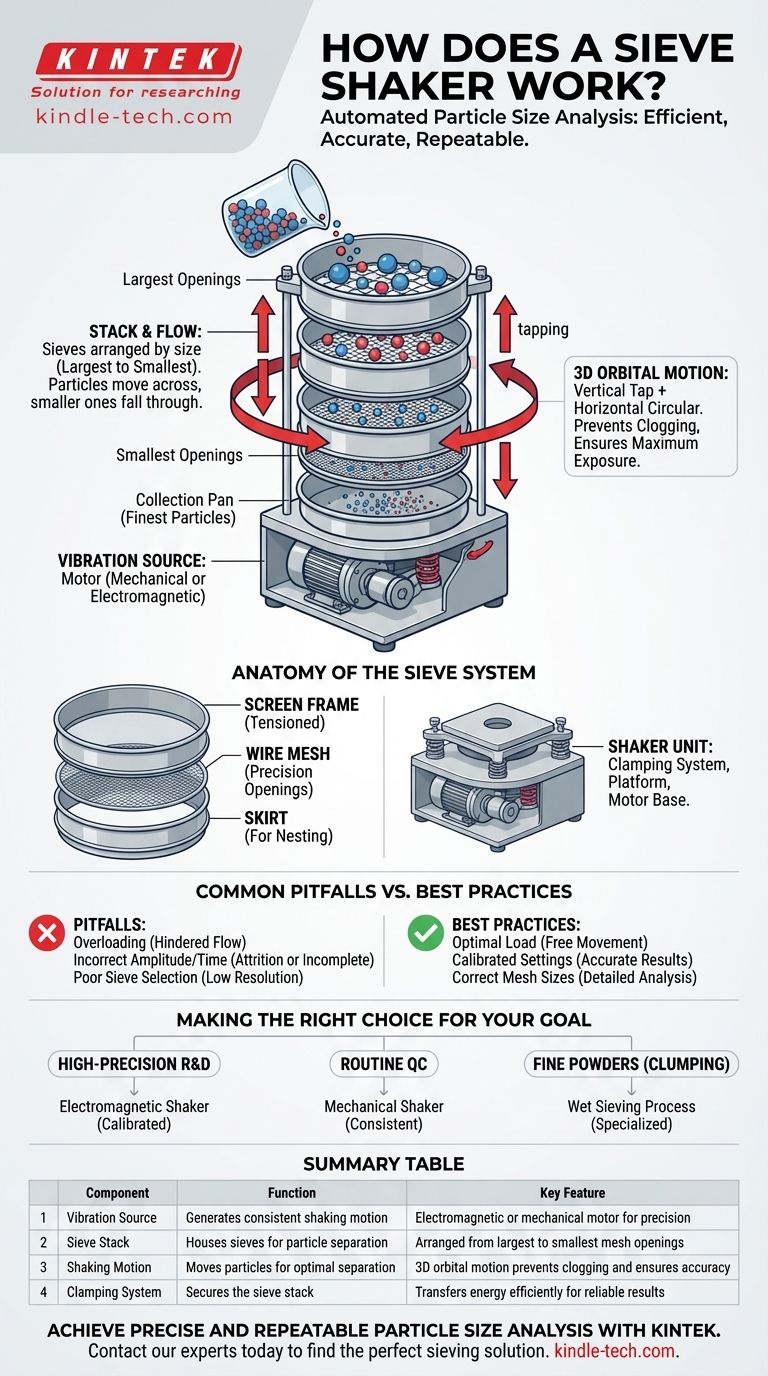

At its core, a sieve shaker automates and standardizes the process of particle size analysis. It uses a powerful motor to apply a consistent vibrational force to a stack of test sieves, which are arranged from the largest opening at the top to the smallest at the bottom. This motion causes the particles in a sample to move across the sieves, with smaller particles progressively falling through the mesh openings until they are sorted by size.

A sieve shaker's primary function is to replace subjective, inconsistent manual sieving with a mechanical process that is efficient, accurate, and highly repeatable. Its value lies in exposing every particle to every sieve opening, ensuring a reliable analysis of a material's particle size distribution.

The Mechanics of Particle Separation

To understand how a sieve shaker works, it's essential to look at its core components and the motion it imparts. The entire system is engineered to ensure particles are separated based on one property alone: their size.

The Vibration Source

The heart of the shaker is its motor, which generates the necessary movement. This is typically a powerful vibration motor or, in more advanced models, an electromagnetic drive.

Electromagnetic shakers create movement through controlled electromagnetic pulses. They are often preferred for analyses that require the highest levels of accuracy and repeatability.

The Sieve Stack and Particle Flow

Sieves are stacked in descending order of opening size. The material sample is placed in the top sieve, which has the largest mesh openings.

As the machine vibrates, particles small enough to pass through the top sieve fall to the one below it. This process repeats down the entire stack. Particles that are too large to pass through a given mesh are retained on that sieve.

A solid collection pan is always placed at the very bottom of the stack to catch the finest particles that pass through the last sieve.

The Optimal Shaking Motion

The most effective sieve shakers do not just shake back and forth. They use a three-dimensional, or orbital, motion that combines a vertical "tapping" with a horizontal circular movement.

The vertical motion helps to lift the particles, keeping the sieve apertures from getting clogged or "blinded." The circular motion moves the particles across the surface, ensuring they have the maximum opportunity to find an opening to pass through.

Anatomy of the Sieve System

A sieve shaker is more than just the machine; it includes the precision-engineered sieves themselves. Each part is designed for accuracy and durability.

The Test Sieve

A single test sieve consists of three parts. The sieve itself is a woven wire mesh, typically made of stainless steel, with precisely measured openings. These range from several inches down to just 20 microns (635 mesh).

The screen frame, usually made of stainless steel or brass, holds this mesh under tension to maintain the accuracy of the openings.

Finally, a skirt on the bottom of the frame allows the sieves to be nested securely on top of each other, forming a stable stack that won't shift during vibration.

The Shaker Unit

The shaker itself is a robust base that houses the motor. It includes a platform to hold the sieve stack and a clamping system to lock it firmly in place, ensuring all vibrational energy is transferred efficiently to the sieves.

Understanding the Trade-offs and Common Pitfalls

While a sieve shaker provides immense benefits over manual methods, achieving accurate results requires avoiding common operational errors. Operator error, not machine failure, is the most common source of inaccurate data.

Sample Overloading

The most frequent mistake is loading too much material into the top sieve. An overloaded sieve prevents particles from moving freely, hindering smaller particles from reaching the mesh and passing through. This results in an inaccurate distribution, skewing the result toward coarser sizes.

Incorrect Amplitude or Time

Every material behaves differently. Too little shaking time or a low amplitude will result in incomplete separation. Conversely, excessive vibration or duration can cause attrition—the grinding down of the particles themselves—which creates more fine particles and corrupts the sample.

Poor Sieve Selection

The choice of mesh sizes for the sieve stack is critical for achieving the desired analytical resolution. Using too few sieves or having large gaps between sizes will give you a low-resolution overview of the particle distribution, potentially missing important details.

Making the Right Choice for Your Goal

To get the most accurate results, you must align your sieving method with your material's properties and your analytical objectives.

- If your primary focus is high-precision R&D: Opt for an electromagnetic sieve shaker and perform tests to calibrate the optimal amplitude and shaking time to prevent particle attrition.

- If your primary focus is routine quality control: A standard mechanical shaker offers excellent repeatability. Ensure you use a consistent sample weight and shaking duration for all tests to guarantee comparable results.

- If you are working with fine powders that clump: Consider a wet sieving process. Using a liquid dispersant (that doesn't react with your material) with a specialized wet-sieving shaker can break up agglomerates for an accurate analysis.

By understanding these mechanical principles, you can transform the sieve shaker from a simple machine into a precision instrument for material characterization.

Summary Table:

| Component | Function | Key Feature |

|---|---|---|

| Vibration Source | Generates consistent shaking motion | Electromagnetic or mechanical motor for precision |

| Sieve Stack | Houses sieves for particle separation | Arranged from largest to smallest mesh openings |

| Shaking Motion | Moves particles for optimal separation | 3D orbital motion prevents clogging and ensures accuracy |

| Clamping System | Secures the sieve stack | Transfers energy efficiently for reliable results |

Achieve precise and repeatable particle size analysis with KINTEK.

Our range of high-quality sieve shakers and test sieves are designed to deliver the accuracy and reliability your laboratory demands. Whether your focus is on high-precision R&D or routine quality control, KINTEK has the right equipment to standardize your process and ensure consistent results.

Contact our experts today to discuss your specific application and find the perfect sieving solution for your needs.

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Mini Planetary Ball Mill Machine for Laboratory Milling

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- What is the disadvantage of sieve shaker method? Uncover Key Limitations in Particle Analysis

- What are sieve shakers used for? Achieve Reliable Particle Size Analysis

- What is the purpose of using high-precision vibrating sieving systems? Master Filler Quality in Wood-Plastic Composites

- Why are high-precision crushing and sieving systems required for aluminosilicate additives? Maximize Alkali Capture

- What is vibratory sieving? Achieve Precise, Reproducible Particle Size Analysis

- How does the fractional sieving step contribute to the efficiency of the microwave-assisted pyrolysis process? Cost Reduction

- What are the disadvantages of sieve shaker method? Uncover the Critical Limitations for Accurate Particle Analysis

- Why use a vibratory sieve shaker for PET powder? Achieve Precise Particle Size Control for Chemical Research