In short, speed is the single most critical operational parameter for a ball mill because it directly controls the physical mechanism of grinding. The rotational speed determines whether the grinding media (the balls) will cascade, cataract, or centrifuge. Only one of these motions—cataracting—produces efficient particle size reduction through impact.

The core challenge is not simply spinning the mill, but achieving a specific "cataracting" motion. This is a precise balance where the speed is high enough to lift the balls near the top of the chamber but slow enough to allow them to fall and crush the material.

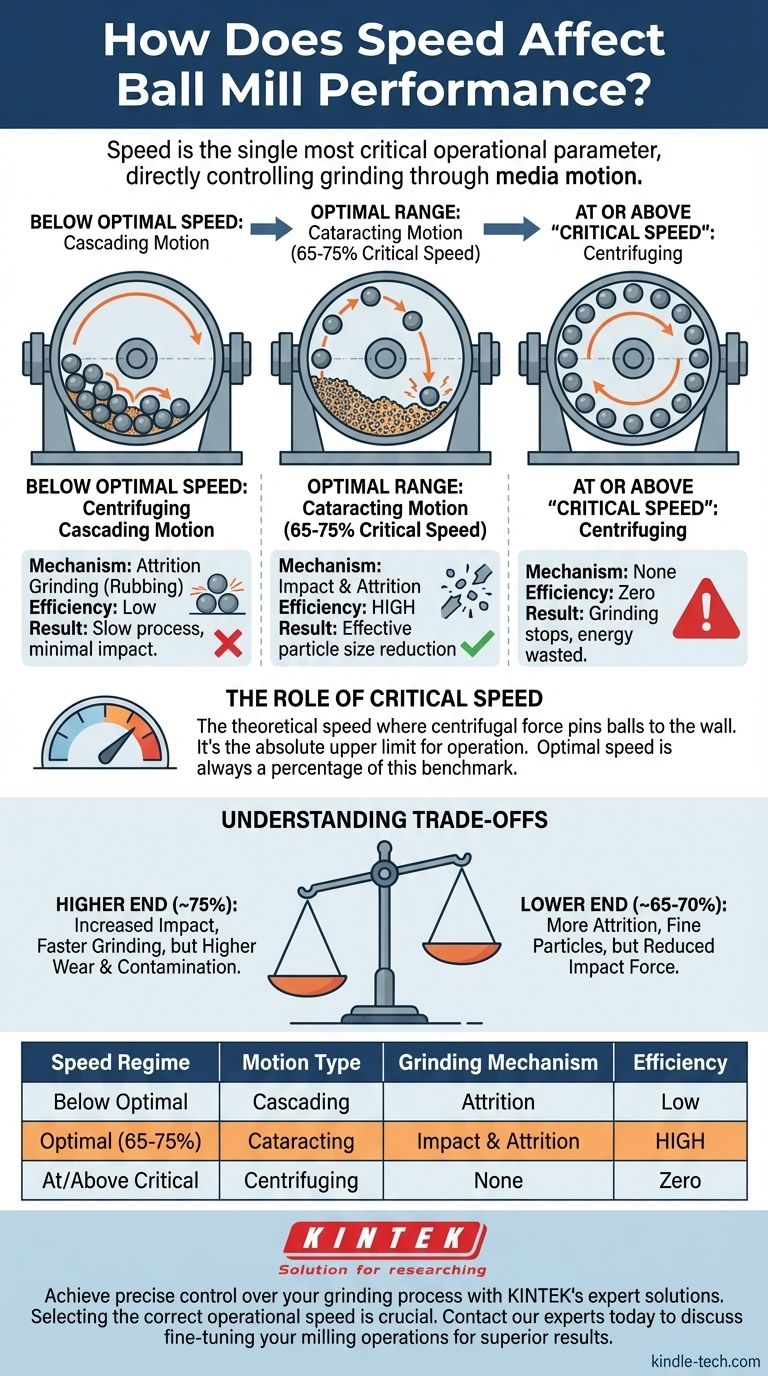

The Three Regimes of Mill Speed

The effectiveness of a ball mill is entirely dependent on the motion of the grinding media inside. This motion is dictated by the rotational speed, which creates three distinct operational regimes.

Below Optimal Speed: Cascading Motion

When the mill rotates too slowly, the balls are not lifted sufficiently. They simply tumble over one another at the bottom of the mill in a cascading motion.

This results primarily in attrition grinding (rubbing and abrasion), which is a slow and often inefficient process for many materials. The high-energy impacts required for rapid size reduction are absent.

At or Above "Critical Speed": Centrifuging

As speed increases, it eventually reaches a point known as critical speed. This is the theoretical speed where the centrifugal force is strong enough to pin the balls to the inner wall of the mill.

When the balls centrifuge, there is no relative motion between them and the material. Grinding completely stops. Running a mill at or above its critical speed is useless and wastes energy.

The Optimal Range: Cataracting Motion

The most efficient grinding occurs within a specific range, typically 65% to 75% of the critical speed. This creates a cataracting motion.

In this state, the balls are carried almost to the top of the mill, detach from the wall, and fall freely onto the material below. This action generates the powerful impact forces necessary to break down particles effectively.

The Role of Critical Speed

Understanding critical speed is essential for proper operation, even though you will never operate a mill at this speed.

Defining the Limit

Critical speed is the calculated rotational velocity where the innermost layer of grinding media will cling to the mill liner due to centrifugal force.

It serves as the absolute upper limit for operation. Any speed beyond this point guarantees that no grinding will occur.

A Benchmark for Operation

The optimal operating speed is always defined as a percentage of the critical speed. This provides a reliable and repeatable benchmark for setting up and optimizing the grinding process for any mill, regardless of its diameter.

Understanding the Trade-offs

Choosing a speed even within the optimal "cataracting" range involves balancing competing factors.

Efficiency vs. Wear

Operating at the higher end of the optimal range (~75% of critical speed) increases the impact energy and can speed up grinding.

However, this also significantly increases the rate of wear on both the grinding media and the mill's internal liner, leading to higher operational costs and potential contamination of the product.

Impact vs. Attrition

The exact speed you choose influences the dominant grinding mechanism.

Higher speeds favor high-energy impacts, which are ideal for breaking down coarse, brittle materials. Lower speeds (while still in the cataract range) reduce impact force but increase the amount of cascading and attrition, which can be beneficial for achieving a very fine final particle size.

How to Set the Right Speed for Your Goal

Use the concept of critical speed to guide your operational settings based on your specific objective.

- If your primary focus is rapid size reduction of brittle materials: Operate in the higher end of the optimal range (~75% of critical speed) to maximize impact forces.

- If your primary focus is producing very fine particles: Consider operating in the lower end of the optimal range (~65-70% of critical speed) to encourage a mix of impact and attrition.

- If your primary focus is minimizing equipment wear and contamination: Use the lowest possible speed within the optimal range that still provides acceptable grinding efficiency.

Ultimately, rotational speed is your primary lever for controlling the entire grinding environment inside the mill.

Summary Table:

| Speed Regime | Motion Type | Grinding Mechanism | Efficiency |

|---|---|---|---|

| Below Optimal | Cascading | Attrition (Rubbing) | Low |

| Optimal (65-75% of Critical) | Cataracting | Impact & Attrition | High |

| At/Above Critical | Centrifuging | None | Zero |

Achieve precise control over your grinding process with KINTEK's expert solutions.

Selecting the correct operational speed is crucial for your ball mill's performance and longevity. KINTEK specializes in high-quality lab equipment and consumables, providing the reliable machinery and expert support your laboratory needs to optimize grinding efficiency, reduce wear, and ensure consistent particle size reduction.

Contact our experts today to discuss how we can help you fine-tune your milling operations for superior results.

Visual Guide

Related Products

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Mini Planetary Ball Mill Machine for Laboratory Milling

- Low-Temperature Water-Cooled Touchscreen Vibratory Ultrafine Pulverizer

- Twin Screw Extruder Plastic Granulation Machine

- Professional Cutting Tools for Carbon Paper Cloth Diaphragm Copper Aluminum Foil and More

People Also Ask

- What is the role of a planetary ball mill in evaluating the processing performance of Miscanthus hydrochar?

- Why is a ball mill utilized for mechanical mixing in PEO-based electrolytes? Achieve Solvent-Free Purity and Homogeneity

- Why is high-energy ball milling equipment utilized for graphene-supported metal catalysts? Superior Methane Oxidation

- What advantages does a planetary ball mill offer over standard ball milling? Boost YAG Powder Sintering Activity

- What is the primary function of a planetary ball mill for h-BN/MAS composites? Master High-Energy Mixing for Ceramics

- What is the primary function of a ball mill during the wet mixing of LNMO? Achieve Microscopic Chemical Uniformity

- What is the primary role of a wet planetary ball mill? Optimize NaFePO4 (Maricite) Precursor Synthesis

- What is the primary function of a planetary ball mill in preparing LLZO? Achieve High-Purity Solid-State Electrolytes