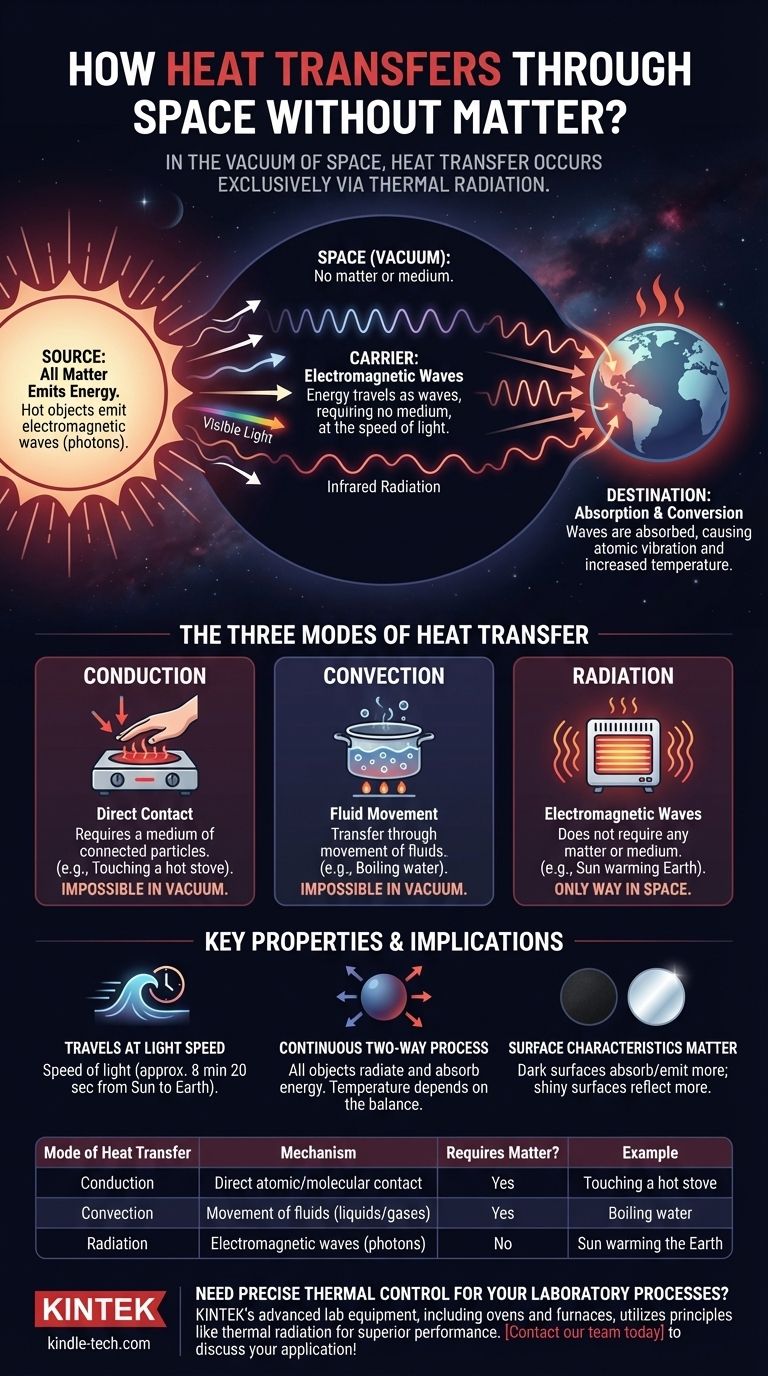

In the vacuum of space, heat is transferred exclusively through a process called thermal radiation. Unlike the more familiar methods of conduction (direct contact) or convection (fluid movement), radiation does not require any matter or medium to carry energy. Instead, energy travels as electromagnetic waves, allowing it to cross the vast, empty distances from a source like the Sun to a destination like Earth.

The critical insight is that heat itself does not travel through space. Instead, hot objects emit energy as electromagnetic radiation (like light and infrared waves). This radiation journeys through the vacuum and is only converted back into heat when it is absorbed by another object.

The Three Modes of Heat Transfer

To understand why radiation is unique, it's helpful to quickly review the other two methods of heat transfer, which are common on Earth but impossible in a vacuum.

Conduction: Heat Through Direct Contact

Conduction is the transfer of heat between substances that are in direct physical contact.

When you touch a hot stove, the fast-vibrating atoms in the hot metal collide with the slower-vibrating atoms in your hand, transferring energy and making your hand feel hot. This process requires a medium of connected particles.

Convection: Heat Through Fluid Movement

Convection is the transfer of heat through the movement of fluids (liquids or gases).

When you boil water, the water at the bottom of the pot gets hot, becomes less dense, and rises. The cooler, denser water at the top sinks to take its place, creating a current that circulates the heat. This process depends entirely on the physical movement of matter.

How Thermal Radiation Works in a Vacuum

Since space is an almost perfect vacuum, neither conduction nor convection can occur. Thermal radiation is the only process that can bridge this gap.

The Source: All Matter Emits Energy

Any object with a temperature above absolute zero (-273.15°C or -459.67°F) has atoms that are in motion. This atomic vibration generates and emits energy in the form of electromagnetic waves, specifically photons.

The hotter an object is, the more energy it radiates. This is why the intensely hot Sun is such a powerful source of radiation.

The Carrier: Electromagnetic Waves

This radiated energy travels outward from the source as electromagnetic waves. These waves are a form of pure energy and do not need any medium to propagate.

The electromagnetic spectrum includes everything from radio waves to gamma rays. The energy from the Sun that reaches us is primarily in the form of visible light and infrared radiation, the latter of which we perceive as heat.

The Destination: Absorption and Conversion

When these electromagnetic waves strike an object, such as the Earth's atmosphere or surface, their energy is absorbed. This absorbed energy causes the atoms in the object to vibrate more rapidly.

This increase in atomic vibration is what we measure and perceive as an increase in temperature, or heat. The energy has completed its journey, converting from thermal energy on the Sun, to radiant energy in space, and back to thermal energy on Earth.

Key Properties and Implications

Understanding radiation involves more than just knowing it happens. Certain properties dictate its behavior and effects.

Radiation Travels at the Speed of Light

Because thermal radiation is a form of light (electromagnetic waves), it travels at the speed of light. This means the energy leaving the Sun takes approximately 8 minutes and 20 seconds to reach Earth.

All Objects Both Radiate and Absorb

Heat transfer via radiation is a continuous, two-way process. While the Earth absorbs massive amounts of radiation from the Sun, it also radiates its own thermal energy back into space.

An object's temperature is determined by the balance between the energy it absorbs and the energy it emits. This balance is critical for understanding planetary climates.

Surface Characteristics Are Crucial

The color and texture of a surface significantly impact how it interacts with radiation.

- Dark, matte surfaces (like asphalt) are excellent absorbers and emitters of radiation.

- Light, shiny surfaces (like ice or a mirror) are poor absorbers and instead reflect most of the radiation that strikes them.

This principle explains why wearing a black shirt on a sunny day feels hotter than wearing a white one.

Making the Right Choice for Your Analysis

To apply these concepts correctly, always identify the environment and the objects involved.

- If your primary focus is heat moving through a solid object: You are observing conduction, where heat is transferred through direct atomic contact.

- If your primary focus is heat circulating in a liquid or gas: You are observing convection, where heat is carried by the physical movement of the fluid itself.

- If your primary focus is heat crossing a vacuum or from a distant source: You are dealing with radiation, where energy is transported by electromagnetic waves.

Understanding thermal radiation is fundamental to grasping how energy moves not just from the Sun to the Earth, but throughout the entire universe.

Summary Table:

| Mode of Heat Transfer | Mechanism | Requires Matter? | Example |

|---|---|---|---|

| Conduction | Direct atomic/molecular contact | Yes | Touching a hot stove |

| Convection | Movement of fluids (liquids/gases) | Yes | Boiling water |

| Radiation | Electromagnetic waves (photons) | No | Sun warming the Earth |

Need precise thermal control for your laboratory processes? Whether you're conducting high-temperature experiments or analyzing material properties, KINTEK's advanced lab equipment, including ovens and furnaces, is engineered for superior performance and reliability. Our solutions help you achieve accurate, consistent results by leveraging principles like thermal radiation. Let KINTEK support your research and laboratory needs with cutting-edge technology and expert guidance. Contact our team today to discuss your specific application!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- What happens to heat generated in a vacuum? Mastering Thermal Control for Superior Materials

- What are the most commonly used metals in a vacuum furnace's hot zone? Discover the Key to High-Purity Processing

- Can an arc happen in a vacuum? Yes, and here's how to prevent it in your high-voltage design.

- At what temperature does molybdenum evaporate? Understanding Its High-Temperature Limits

- What are the safety precautions during heat treatment? A Guide to Managing Extreme Heat, Gases & Hazards