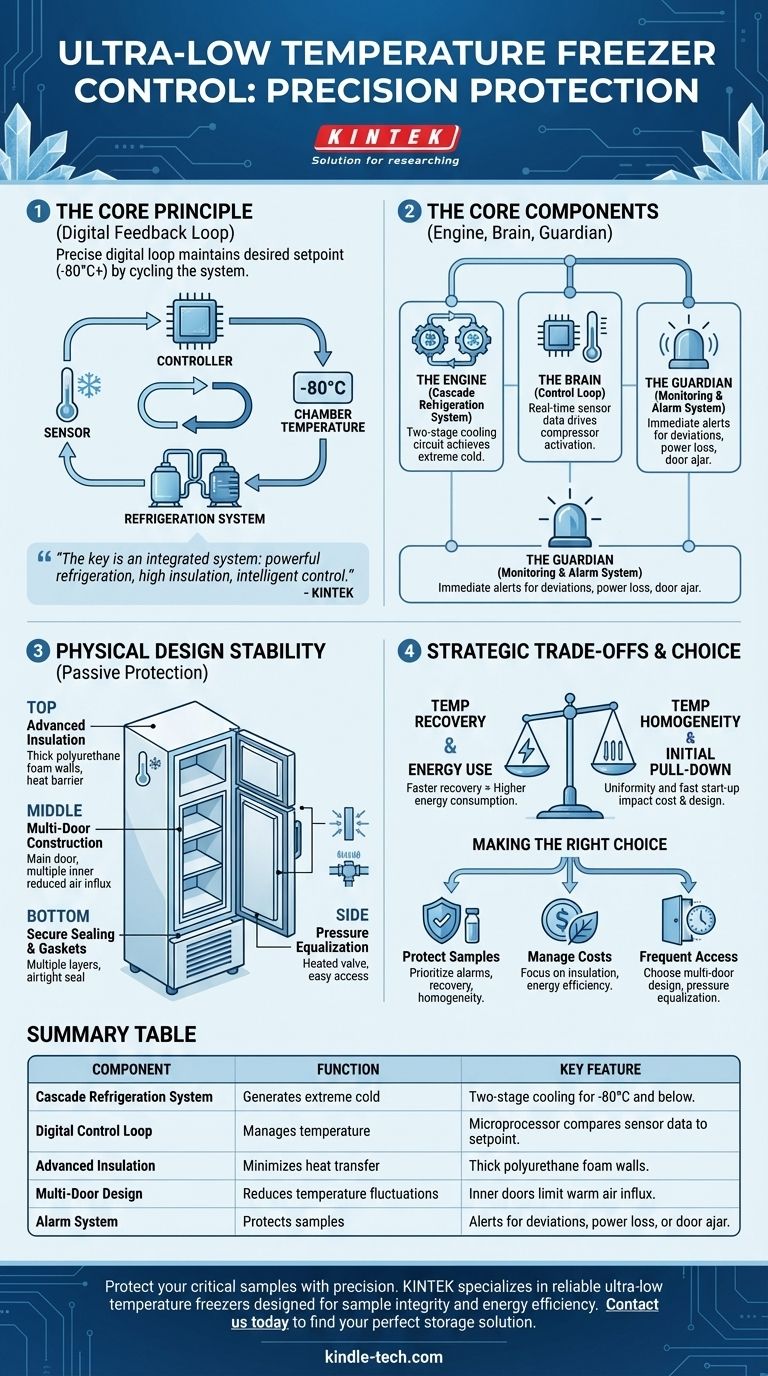

At its core, an ultra-low temperature (ULT) freezer controls its environment through a precise digital feedback loop. Internal sensors constantly measure the temperature, feeding this data to a controller that compares it to your desired setpoint—typically -80°C or colder—and cycles the refrigeration system on or off to maintain that exact temperature.

The key is not a single component, but an integrated system. Effective temperature control in a ULT freezer is the result of a powerful refrigeration cycle, a highly insulated physical structure, and an intelligent electronic control system working in concert to achieve and maintain extreme cold with high stability.

The Core Components of Temperature Control

To reliably preserve sensitive biological materials like vaccines, DNA, and tissues, ULT freezers deploy a multi-faceted approach. This system can be broken down into three primary functions: generating cold, intelligently managing it, and ensuring its integrity.

The Refrigeration System (The Engine)

The heart of a ULT freezer is its cascade refrigeration system. This design uses two separate refrigeration circuits that are thermally connected.

The first circuit cools the second, allowing the second circuit to reach much lower temperatures than a single system could. This powerful "engine" is what provides the raw cooling power needed to achieve temperatures of -80°C and below.

The Control Loop (The Brain)

This is the active management system. A temperature sensor, often a highly accurate thermocouple or resistance temperature detector (RTD), is placed inside the chamber.

This sensor provides real-time temperature data to a microprocessor-based controller. The controller's algorithm constantly compares this reading to the user-defined setpoint and activates the cascade compressors when the temperature rises even slightly above the target.

The Monitoring & Alarm System (The Guardian)

Because the samples stored are often invaluable, control is not left to the automated system alone. All ULT freezers incorporate visual and audible alarm systems.

These alarms immediately alert users to any significant temperature deviations, power failures, or door-ajar events, providing a critical window to prevent sample loss.

How Physical Design Ensures Stability

A freezer's ability to maintain temperature is just as dependent on its physical construction as its refrigeration system. These passive features are designed to minimize heat transfer from the outside world and reduce the workload on the compressors.

Advanced Insulation

The walls of a ULT freezer are filled with thick, high-efficiency insulation, typically a polyurethane foam material. This creates a formidable thermal barrier, drastically slowing the rate at which ambient heat can penetrate the storage chamber.

Multi-Door Construction

Nearly all upright ULT freezers feature a main, insulated outer door and multiple inner doors. This design is critical for stability.

When you open the outer door, you only expose one small section at a time. This significantly reduces the influx of warm, moist air, protecting the samples in other compartments and allowing the freezer to recover its set temperature much more quickly after access.

Secure Sealing and Gaskets

The outer door is sealed with multiple layers of flexible, silicone-like gaskets. A robust latching mechanism, often an ergonomic handle, compresses these gaskets to create an airtight seal, preventing temperature leaks and reducing frost formation.

Pressure Equalization

When warm air is introduced and rapidly cooled, it creates a strong vacuum inside the freezer, which can make the door difficult to open. Modern freezers include a heated pressure-release valve that briefly warms the air inside the port to equalize the pressure, allowing for easy access.

Understanding the Trade-offs

Selecting or operating a ULT freezer involves balancing performance characteristics. Understanding these trade-offs is key to matching the equipment to your specific laboratory needs.

Temperature Recovery vs. Energy Use

Rapid temperature recovery after a door opening is a critical feature for busy labs with frequent sample access. However, freezers that recover faster often have more powerful compressors that consume more energy.

Temperature Homogeneity

Temperature homogeneity refers to the uniformity of temperature throughout the entire storage chamber. While a freezer might be set to -80°C, some spots near the door or walls may be slightly warmer. High-performance models are engineered to minimize these variations, but this often comes at a higher initial cost.

Initial Pull-Down Time

The quick temperature pull-down is the time it takes a new or warm freezer to reach its target operating temperature. While not a daily concern, a faster pull-down time gets a unit operational more quickly after installation or a lengthy defrost cycle.

Making the Right Choice for Your Goal

Your primary objective dictates which features of temperature control are most important.

- If your primary focus is protecting irreplaceable samples: Prioritize models with the most robust alarm systems, fast temperature recovery speeds, and excellent temperature homogeneity.

- If your primary focus is managing operational costs: Look for freezers with the most advanced insulation technology and energy-efficient compressor systems to lower electricity consumption.

- If your primary focus is frequent sample access: Choose a unit with a superior multi-door design and an effective pressure equalization valve to minimize temperature fluctuations and ensure user convenience.

Understanding these integrated systems empowers you to select and operate a freezer that provides maximum protection for your critical work.

Summary Table:

| Component | Function | Key Feature |

|---|---|---|

| Cascade Refrigeration System | Generates extreme cold | Two-stage cooling for -80°C and below |

| Digital Control Loop | Manages temperature | Microprocessor compares sensor data to setpoint |

| Advanced Insulation | Minimizes heat transfer | Thick polyurethane foam walls |

| Multi-Door Design | Reduces temperature fluctuations | Inner doors limit warm air influx |

| Alarm System | Protects samples | Alerts for deviations, power loss, or door ajar |

Protect your critical samples with precision. KINTEK specializes in reliable ultra-low temperature freezers and lab equipment designed for maximum sample integrity and energy efficiency. Our experts will help you select the ideal ULT freezer for your specific laboratory needs—whether your priority is sample security, operational cost savings, or frequent access. Contact us today to find your perfect storage solution!

Visual Guide

Related Products

- 408L Advanced Vertical Laboratory Ultra Low Temperature Freezer for Critical Research Material Preservation

- 108L Vertical Ultra Low Temperature ULT Freezer

- 508L Advanced Vertical Ultra Low Temperature Freezer for Critical Laboratory Storage

- 708L Ultra Low Temperature Freezer High Performance Laboratory Freezer

- 208L Advanced Precision Laboratory Ultra Low Temperature Freezer for Cold Storage

People Also Ask

- What is the temperature control capability of ultra-low freezers? Precise Stability Down to -86°C

- Why are ULT freezers considered vital equipment in labs? Ensuring Uncompromised Sample Integrity for Critical Research

- What is the purpose of ultra-low temperature (ULT) freezers? Preserve Critical Biological Samples

- What are the key features to look for in an ultra-low temperature freezer for mRNA vaccine storage? Essential Features for Absolute Vaccine Integrity

- How does fast temperature recovery benefit ultra-low freezers? Protect Sample Integrity and Lab Efficiency