At its core, an ultra-low temperature (ULT) freezer's interior is engineered to solve a fundamental conflict: how to store the maximum number of samples while ensuring every single sample remains at a stable, uniform, and extremely cold temperature. This is achieved through a carefully designed system of modular shelving and racks that facilitates consistent cold air circulation, which is paramount for preserving the viability of sensitive biological materials.

The design of a ULT freezer's interior is not merely about storage; it is a critical component of the cooling system itself. Every shelf, rack, and compartment is deliberately engineered to manage airflow and temperature, directly impacting the long-term safety and integrity of your samples.

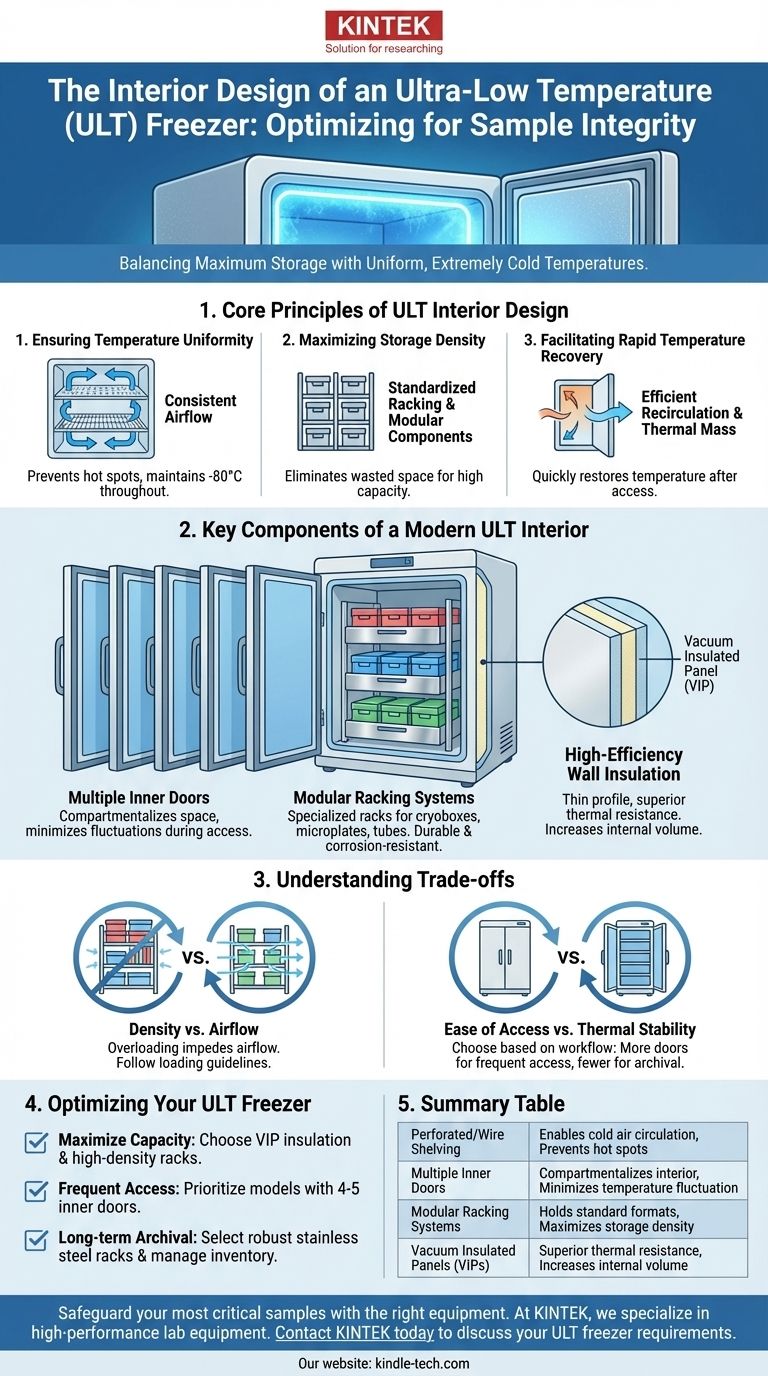

The Core Principles of ULT Interior Design

To appreciate the design, you must understand the physics and priorities at play. The interior is not passive shelving; it is an active part of the freezer's performance.

Principle 1: Ensuring Temperature Uniformity

The single most important goal is to eliminate temperature gradients. A freezer reading -80°C on its display could have internal "hot spots" of -70°C or even -65°C, which can be catastrophic for sample integrity.

Interior design combats this with shelving—often perforated or wire-frame—that allows cold air to circulate freely and naturally via convection. This prevents pockets of warmer air from getting trapped, ensuring the entire chamber maintains a uniform temperature.

Principle 2: Maximizing Storage Density

Laboratory space is expensive and limited. ULT freezer design addresses this by using modular interior components to achieve the highest possible storage capacity within a given footprint.

Standardized racking systems are designed to perfectly fit common storage formats like 2-inch or 3-inch cryoboxes. This eliminates wasted space and allows for predictable, organized, and dense sample archival.

Principle 3: Facilitating Rapid Temperature Recovery

Every time the freezer door is opened, cold air rushes out and is replaced by warm, moist ambient air. The interior design plays a crucial role in how quickly the system can recover to its setpoint.

Well-designed racks and shelving allow the freezer's cooling system to efficiently recirculate cold air throughout the chamber, rapidly removing heat and restoring temperature uniformity. The thermal mass of the racks themselves can also help stabilize the temperature of the surrounding samples during brief door openings.

Key Components of a Modern ULT Freezer Interior

Several key features work together to achieve these principles. Understanding them helps you evaluate the effectiveness of a specific model.

Multiple Inner Doors

This is one of the most critical design elements. Instead of a single large space, the interior is divided into multiple compartments, each protected by its own insulated inner door.

When you need to access samples in one compartment, you only expose that small section to ambient air. The other compartments remain sealed and protected, dramatically minimizing the overall temperature fluctuation within the freezer.

Modular Racking Systems

Modern ULT freezers feature highly modular interiors. Racks are not just simple shelves; they are specialized cassettes designed for specific consumables like cryoboxes, microplates, or conical tubes.

These systems are typically made of stainless steel for durability and corrosion resistance. Their precise dimensions ensure a snug fit, preventing sample boxes from shifting while still allowing for necessary airflow between racks.

High-Efficiency Wall Insulation

The interior chamber's performance is directly tied to the exterior walls. Modern freezers use Vacuum Insulated Panels (VIPs) in conjunction with traditional foam.

VIPs provide exceptional thermal resistance with a much thinner profile than foam alone. This allows for thinner freezer walls, which directly translates to a larger internal storage volume for the same external footprint—a key factor in maximizing lab space.

Understanding the Trade-offs

No design is without its compromises. Being aware of them is key to proper use and purchasing decisions.

Density vs. Airflow

This is the central trade-off. While high-density racks maximize capacity, overloading a freezer or pushing racks tightly against each other can impede airflow.

This user-induced error can defeat the engineered circulation design, creating the very temperature gradients the freezer is meant to prevent. It is critical to follow manufacturer guidance on loading configurations.

Ease of Access vs. Thermal Stability

A freezer with five inner doors provides better thermal stability than one with two, but it also means more barriers to navigate when retrieving samples.

The ideal configuration depends on your workflow. For frequently accessed samples, more compartments are better. For long-term, untouched archival, fewer inner doors might be acceptable.

Cost vs. Advanced Features

Features like stainless steel interiors, extensive modular racking, and multiple inner doors add to the cost. A basic model may have a simpler interior with fixed shelving.

While less expensive upfront, a basic design may offer lower storage density and poorer temperature recovery, posing a greater long-term risk to valuable samples.

Optimizing Your ULT Freezer for Sample Integrity

Your choice and use of a freezer's interior should align directly with your scientific goals. Use these guidelines to make an informed decision.

- If your primary focus is maximizing capacity: Opt for a model with high-quality VIP insulation and invest in a full complement of high-density racks designed specifically for your standard cryoboxes.

- If your primary focus is sample access frequency: Prioritize a freezer with the maximum number of inner doors (four or five) to protect undisturbed samples from temperature fluctuations during daily retrievals.

- If your primary focus is long-term archival: Select robust, corrosion-resistant stainless steel racks and implement a strict inventory system to minimize the duration and frequency of door openings.

Ultimately, understanding that the interior is a dynamic system for managing temperature is the key to safeguarding your irreplaceable work.

Summary Table:

| Design Feature | Primary Function | Key Benefit |

|---|---|---|

| Perforated/Wire Shelving | Enable cold air circulation | Prevents hot spots, ensures temperature uniformity |

| Multiple Inner Doors | Compartmentalize the interior | Minimizes temperature fluctuation during access |

| Modular Racking Systems | Hold standard cryoboxes and tubes | Maximizes storage density and organization |

| Vacuum Insulated Panels (VIPs) | Provide superior thermal resistance | Increases internal storage volume for a given footprint |

Safeguard your most critical samples with the right equipment. The interior design of your ultra-low temperature freezer is fundamental to sample integrity. At KINTEK, we specialize in providing high-performance lab equipment, including ULT freezers with advanced interior designs tailored to your specific storage needs—whether for high-density archival, frequent access, or long-term stability.

Let our experts help you select a solution that ensures uniform temperature, rapid recovery, and maximum capacity for your laboratory. Contact KINTEK today to discuss your ULT freezer requirements and protect your valuable research.

Visual Guide

Related Products

- 158L Precision Vertical Ultra Low Freezer for Laboratory Applications

- 938L Vertical Ultra Low Temperature Freezer for Advanced Laboratory Storage

- 108L Vertical Ultra Low Temperature ULT Freezer

- 408L Advanced Vertical Laboratory Ultra Low Temperature Freezer for Critical Research Material Preservation

- 808L Precision Laboratory Vertical Ultra Low Temperature Freezer

People Also Ask

- How should frost be removed from Ultra-Low Temperature Freezers? Protect Your Samples and Equipment

- What is convection-based cooling in ultra-low temperature freezers? Achieve Superior Temperature Stability for Your Samples

- What types of materials are commonly stored in ultra low temperature freezers? Preserving Cells, Vaccines & Biomolecules

- Why are ultra-low temperature freezers important in scientific research? Ensure Sample Integrity and Reproducibility

- Why are ULT freezers considered vital equipment in labs? Ensuring Uncompromised Sample Integrity for Critical Research