At their core, an energy-efficient Ultra-Low Temperature (ULT) freezer is a system meticulously designed to combat heat transfer. Its efficiency stems from a combination of advanced physical insulation, high-integrity door and gasket systems, and smart operational features that work together to minimize the energy required to maintain extreme cold, typically between -60°C and -90°C.

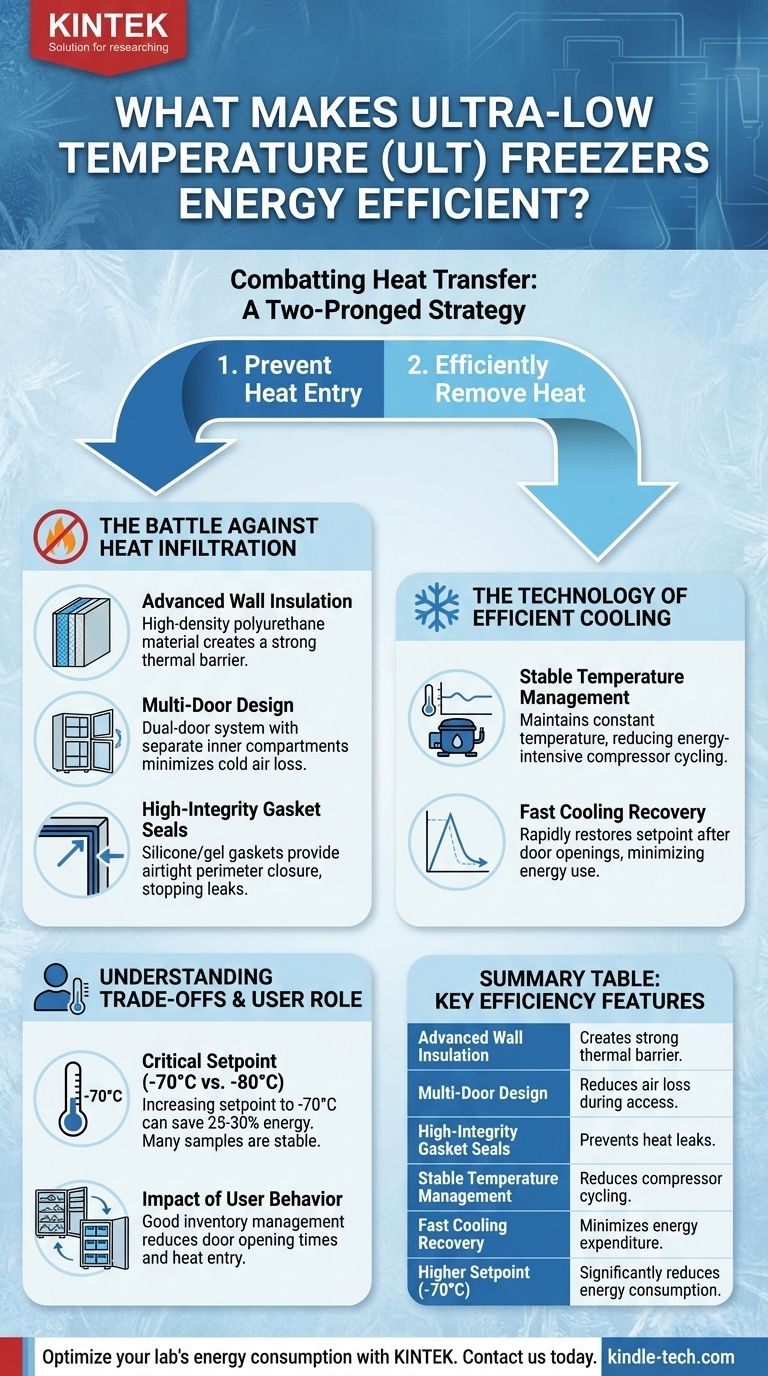

The central principle of ULT freezer efficiency is not a single technology, but a two-pronged strategy: first, physically preventing ambient heat from entering the chamber, and second, using technology that removes any infiltrated heat as economically as possible.

The Battle Against Heat Infiltration

A standard ULT freezer can consume as much energy as an average household in a single day. The primary driver of this consumption is the constant work required to counteract heat leaking in from the surrounding environment. Efficient models aggressively address this fundamental problem.

Advanced Wall Insulation

The first line of defense is the freezer's cabinet walls. These are packed with highly effective insulation, such as polyurethane material, to create a strong thermal barrier.

This insulation significantly slows the natural process of heat transfer from the warmer lab environment into the cold interior.

Multi-Door Design

Efficient ULT freezers almost always feature a dual-door system. An insulated outer door provides the main seal against the room.

Inside, one or more inner doors create separate compartments. When you open the outer door, these inner doors remain closed, dramatically reducing the amount of cold air that escapes and warm, moist air that enters.

High-Integrity Gasket Seals

The point where the doors meet the cabinet is a critical vulnerability for heat leaks. To prevent this, efficient freezers use pliable, silicone or gel-like gasket seals around the full perimeter of each door.

These seals are often compressed by an external knob or latching mechanism, creating an airtight closure that stops infiltration.

The Technology of Efficient Cooling

While preventing heat entry is crucial, some heat transfer is inevitable, especially when the door is opened. Efficient technology is about removing that heat without wasting electricity.

Stable Temperature Management

Modern ULT freezers are engineered to maintain a highly constant temperature. This stability reduces the number of times the high-draw cooling compressor has to cycle on and off.

Fewer, more efficient cycles lead to significant energy savings over time.

Fast Cooling Recovery

Features often marketed as "fast cooling technology" are designed to bring the temperature back down to the setpoint quickly after a door opening.

By minimizing the duration of a high-temperature state, the system reduces the overall energy expenditure needed for recovery.

Understanding the Trade-offs

Achieving high efficiency involves operational choices and recognizing inherent limitations. Understanding these factors is key to maximizing performance and cost savings.

The Critical Role of Setpoint Temperature

The single most impactful user-controlled factor is the temperature setpoint. While many freezers operate at -80°C, research suggests many samples are stable at -70°C.

Increasing the setpoint by just 10 degrees can reduce energy consumption by up to 25-30%, as the freezer doesn't have to work as hard to fight the temperature difference with the ambient room.

The Impact of User Behavior

An efficient freezer can be undermined by inefficient practices. A disorganized freezer leads to longer door opening times as users search for samples, allowing more heat to enter.

Implementing an inventory management system and regularly cleaning out old or unnecessary samples are essential operational practices for maintaining efficiency.

Making the Right Choice for Your Goal

Your approach to efficiency depends on whether you are optimizing an existing unit or purchasing a new one.

- If your primary focus is immediate energy reduction: Adjust the setpoint to -70°C (if your sample protocols allow) and implement a strict sample inventory system to minimize door opening times.

- If your primary focus is long-term operational savings: When purchasing a new unit, prioritize models with multi-door designs, robust gasket systems, and proven temperature stability and recovery performance.

Ultimately, mastering ULT freezer efficiency is about understanding that the hardware's design and your lab's daily practices are two parts of the same crucial system.

Summary Table:

| Efficiency Feature | Key Benefit |

|---|---|

| Advanced Wall Insulation | Creates a strong thermal barrier to slow heat transfer. |

| Multi-Door Design | Reduces cold air loss and warm air entry when accessing samples. |

| High-Integrity Gasket Seals | Provides an airtight closure to prevent heat leaks. |

| Stable Temperature Management | Reduces compressor cycling, leading to significant energy savings. |

| Fast Cooling Recovery | Minimizes energy expenditure after door openings. |

| Higher Setpoint (-70°C) | Can reduce energy consumption by 25-30% compared to -80°C. |

Optimize your lab's energy consumption and sample security with KINTEK.

Choosing the right Ultra-Low Temperature freezer is critical for both your research integrity and your operational budget. KINTEK specializes in providing reliable lab equipment, including energy-efficient ULT freezers, designed to meet the demanding needs of modern laboratories.

Our experts can help you select a unit that combines advanced insulation, precise temperature control, and robust design to ensure long-term savings and unparalleled performance.

Ready to enhance your lab's efficiency? Contact our team today to discuss your specific requirements and find the perfect ULT solution for your laboratory.

Visual Guide

Related Products

- 158L Precision Vertical Ultra Low Freezer for Laboratory Applications

- 508L Advanced Vertical Ultra Low Temperature Freezer for Critical Laboratory Storage

- 938L Vertical Ultra Low Temperature Freezer for Advanced Laboratory Storage

- 808L Precision Laboratory Vertical Ultra Low Temperature Freezer

- 408L Advanced Vertical Laboratory Ultra Low Temperature Freezer for Critical Research Material Preservation

People Also Ask

- How should frost be removed from Ultra-Low Temperature Freezers? Protect Your Samples and Equipment

- Why are ULT freezers considered vital equipment in labs? Ensuring Uncompromised Sample Integrity for Critical Research

- What is the purpose of ultra-low temperature (ULT) freezers? Preserve Critical Biological Samples

- What is convection-based cooling in ultra-low temperature freezers? Achieve Superior Temperature Stability for Your Samples

- How do ultra-low temperature freezers work? Unlocking the Secrets of -86°C Sample Preservation