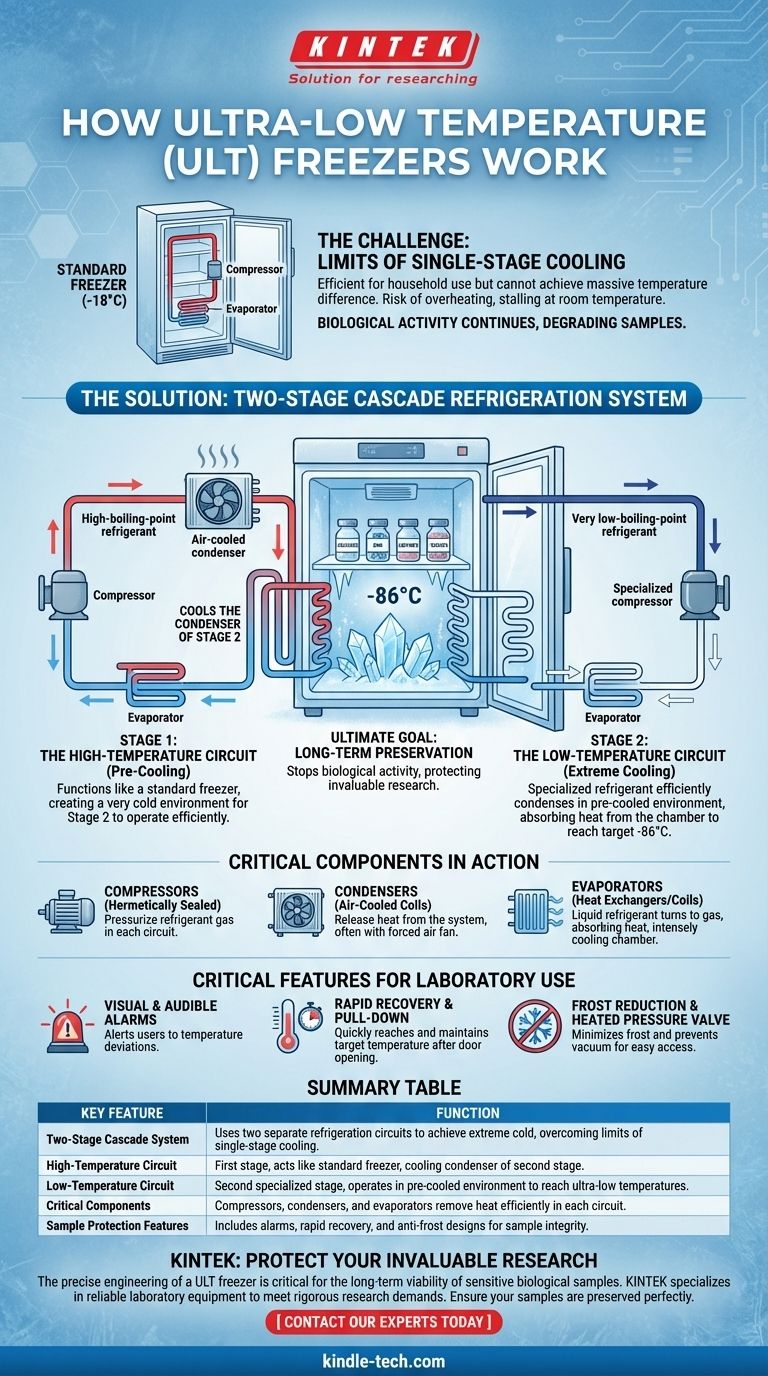

At their core, ultra-low temperature (ULT) freezers work by using a two-stage cascade refrigeration system. Unlike a standard freezer that uses a single cooling circuit, a ULT freezer employs two separate circuits in a relay. The first circuit cools the second, allowing the second circuit to achieve the extreme temperatures, typically between -40°C and -86°C, necessary for preserving sensitive biological samples.

The critical insight is that a single refrigeration system has physical limits. To overcome them, ULT freezers use a "relay race" approach where one cooling system pre-cools a second, specialized system, enabling it to remove heat far more effectively and reach extraordinarily low temperatures.

Why a Standard Freezer Isn't Enough

A household freezer, which operates around -18°C, uses a single refrigeration loop. This system is efficient for its purpose but simply cannot create the massive temperature difference required to reach -86°C in a standard room.

The Limits of Single-Stage Cooling

A single compressor trying to bridge such a large temperature gap becomes highly inefficient and risks overheating. The refrigerant gas would be difficult to condense back into a liquid at room temperature, stalling the entire cycle.

The Need for Extreme Preservation

Laboratories require these ultra-low temperatures for the long-term storage of invaluable materials like vaccines, DNA, enzymes, and tissues. At standard freezer temperatures, biological activity can continue, slowly degrading these samples over time.

The Cascade System: A Two-Stage Solution

The cascade system is the engineering solution to this problem. It breaks the cooling process into two manageable stages, with each stage optimized for a specific temperature range.

Stage 1: The High-Temperature Circuit

The first circuit functions much like a standard freezer. It uses a high-boiling-point refrigerant to pull heat out of the system.

However, instead of cooling the freezer's internal chamber, its primary job is to cool the condenser of the second circuit. It essentially creates a very cold environment for the second stage to work in.

Stage 2: The Low-Temperature Circuit

This second circuit is the specialized stage that does the heavy lifting. It uses a different refrigerant with a very low boiling point.

Because its condenser is already being chilled by the first stage, this second circuit can efficiently condense its refrigerant gas and continue the cycle, ultimately absorbing heat from the freezer's interior and reaching the target -86°C.

Key Components in Action

- Compressors: Each circuit has a hermetically sealed compressor that pressurizes the refrigerant gas.

- Condensers: These are typically air-cooled coils that release heat from the system into the surrounding room. A fan drives forced air circulation to improve this heat transfer.

- Evaporators: Inside the chamber, steel plate heat exchangers or coils act as evaporators. Here, the liquid refrigerant turns to gas, absorbing heat from the samples and making the chamber intensely cold.

Critical Features for Laboratory Use

Beyond the core cooling mechanism, ULT freezers are defined by features that ensure the safety and integrity of the materials they protect.

Ensuring Sample Integrity

The most important goal is protecting the samples. Features like visual and audible alarms are standard, immediately alerting users to temperature deviations that could compromise years of research.

Maintaining Performance

A ULT freezer must not only get cold but stay cold. Quick temperature pull-down allows the unit to reach its target quickly, while rapid temperature recovery after a door opening is crucial to minimize sample exposure to warmer air.

Practical Design and Safety

Engineers incorporate features to reduce frost formation, which can interfere with seals and access. A heated pressure release valve is often included to prevent a vacuum from forming after the door is closed, making it easier to reopen.

Making the Right Choice for Your Goal

Selecting a ULT freezer involves more than just looking at the temperature range; it's about understanding the entire system's role in protecting your work.

- If your primary focus is long-term viability of critical samples: The stability and deep cold of a cascade refrigeration system are non-negotiable.

- If your primary focus is operational security and minimizing risk: Prioritize models with robust alarm systems, rapid temperature recovery, and strong construction to prevent sample loss.

Ultimately, a ULT freezer is an engineered ecosystem designed for one purpose: to stop time for the invaluable biological materials stored within it.

Summary Table:

| Key Feature | Function |

|---|---|

| Two-Stage Cascade System | Uses two separate refrigeration circuits to achieve extreme cold, overcoming the limits of single-stage cooling. |

| High-Temperature Circuit | The first stage acts like a standard freezer, cooling the condenser of the second, low-temperature circuit. |

| Low-Temperature Circuit | The specialized second stage, operating in a pre-cooled environment, achieves the target ultra-low temperatures. |

| Critical Components | Compressors, condensers, and evaporators work together in each circuit to remove heat efficiently. |

| Sample Protection Features | Includes alarms, rapid temperature recovery, and anti-frost designs to ensure sample integrity. |

Protect your invaluable research with confidence. The precise engineering of an ultra-low temperature freezer is critical for the long-term viability of sensitive biological samples like vaccines, tissues, and enzymes. At KINTEK, we specialize in providing reliable laboratory equipment, including ULT freezers, designed to meet the rigorous demands of modern research. Ensure your samples are preserved perfectly — contact our experts today to find the ideal solution for your laboratory's needs.

Visual Guide

Related Products

- 408L Advanced Vertical Laboratory Ultra Low Temperature Freezer for Critical Research Material Preservation

- 708L Ultra Low Temperature Freezer High Performance Laboratory Freezer

- 208L Advanced Precision Laboratory Ultra Low Temperature Freezer for Cold Storage

- 608L Essential Laboratory Ultra Low Temperature Freezer For Critical Sample Preservation

- 808L Precision Laboratory Vertical Ultra Low Temperature Freezer

People Also Ask

- What is the purpose of ultra-low temperature (ULT) freezers? Preserve Critical Biological Samples

- How is temperature controlled in ultra low temperature freezers? A Guide to Stable -80°C Storage

- What are the key features to look for in an ultra-low temperature freezer for mRNA vaccine storage? Essential Features for Absolute Vaccine Integrity

- How are advancements in compressor technology and refrigerant fluids improving ULT freezers? Boost Efficiency & Cut Costs

- Why are ULT freezers considered vital equipment in labs? Ensuring Uncompromised Sample Integrity for Critical Research