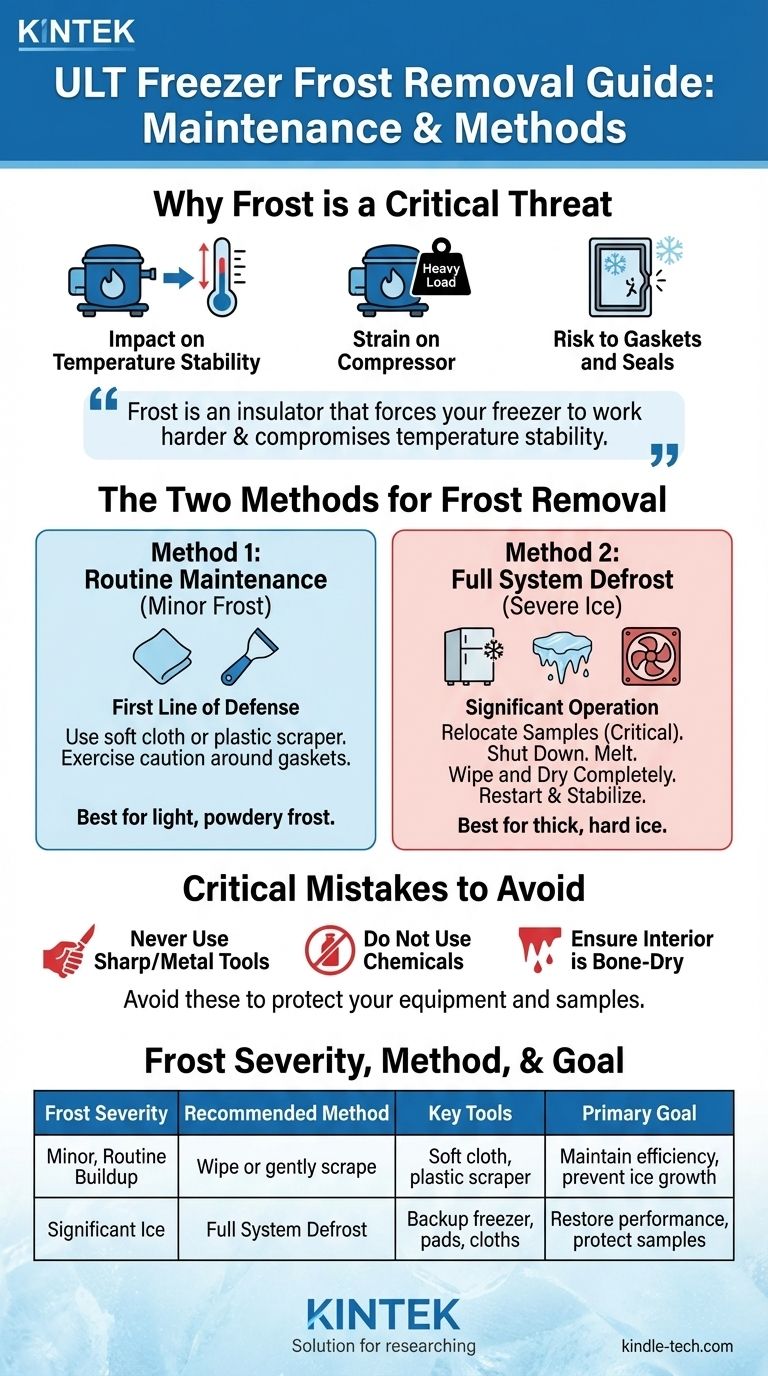

Frost removal in an Ultra-Low Temperature (ULT) freezer is a critical maintenance task that must be approached with two distinct methods depending on the severity. For minor, routine buildup, frost can be wiped away with a soft cloth or gently removed with a plastic scraper. For significant ice accumulation that compromises the door seal or internal space, a complete system defrost is the only safe and effective solution.

Frost is not a simple nuisance; it is an insulator that forces your freezer to work harder, compromises temperature stability, and risks the integrity of your samples. The most effective strategy is not just removal, but a disciplined approach to prevention that minimizes the need for a disruptive full defrost.

Why Frost is a Critical Threat to Your Freezer

Frost buildup is a direct indicator of moisture entering the system. This moisture, primarily from ambient air during door openings, creates a cascade of problems that go far beyond simple inconvenience.

The Impact on Temperature Stability

Frost acts as an insulator. As it builds on interior surfaces and around gaskets, it prevents the efficient transfer of heat out of the freezer. This forces the compressor to run longer and harder to maintain its setpoint, potentially leading to wider temperature fluctuations and placing your valuable samples at risk.

The Strain on Your Freezer's Compressor

A compressor fighting against the insulation of frost is a compressor under constant strain. This leads directly to higher energy consumption and significantly increases the wear and tear on the freezer's most critical and expensive component, shortening its operational lifespan.

The Risk to Gaskets and Seals

Ice can form on and around the door gaskets. This can physically damage the soft gasket material or create tiny gaps that prevent a perfect seal. A compromised seal allows more humid air to enter the freezer, accelerating frost buildup and creating a vicious cycle of inefficiency.

The Two Methods for Frost Removal

Your approach should be dictated by the amount of frost present. Treating a major ice problem with a minor tool is ineffective, and performing a full defrost for a light dusting of frost is inefficient.

Method 1: Routine Maintenance for Minor Frost

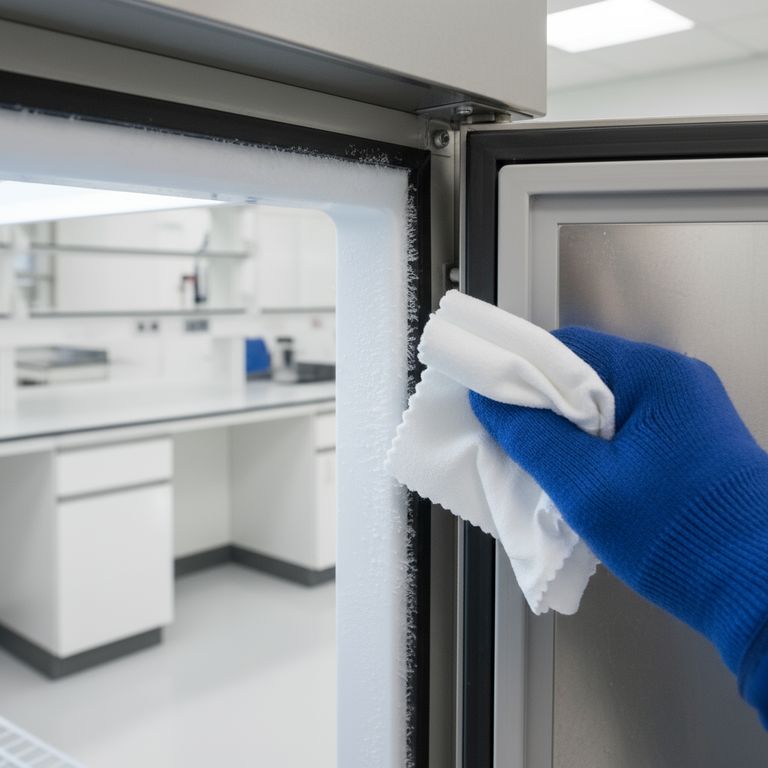

This is the first line of defense and should be part of your regular lab maintenance schedule.

For light, powdery frost on inner doors and shelves, use a soft, dry cloth to wipe it away. For slightly denser patches, a soft brush or plastic scraper can be used. Exercise extreme caution around door gaskets to avoid tearing or puncturing the material.

Method 2: The Full System Defrost for Severe Ice

When ice is thick, hard, and interfering with door closure, a full defrost is required. This is a significant operation that requires careful planning.

- Relocate Samples: Move all samples to a designated, pre-chilled backup ULT freezer. This is the most critical step for protecting your assets.

- Shut Down the Unit: Power down the freezer and unplug it from the wall.

- Melt the Ice: Prop the doors open to allow the ice to melt naturally at room temperature. You can place absorbent pads or shallow trays to catch meltwater.

- Wipe and Dry Completely: Once all ice has melted, use soft cloths to wipe down the entire interior. Ensure every surface is completely dry, as any remaining moisture will immediately turn into frost when the unit is restarted.

- Restart and Stabilize: Close the doors, power the freezer on, and allow it to return to its setpoint temperature. This can take several hours. Do not reload samples until the unit is stable.

Critical Mistakes to Avoid

A poorly executed defrost can cause more damage than the frost itself. Adhering to these warnings is non-negotiable for protecting your equipment and samples.

Never Use Sharp or Metal Tools

Using a metal scraper, screwdriver, or any sharp object is extremely risky. You can easily puncture the soft door gasket or, in a worst-case scenario, puncture an interior wall and damage the sealed refrigeration system, resulting in a catastrophic failure.

Do Not Use Alcohols or Chemical Solvents

Chemicals like isopropyl alcohol can make plastics brittle and damage the integrity of gaskets and seals. Clean, room-temperature water and a soft cloth are all that is needed after the ice has melted.

Ensure the Interior is Bone-Dry

Leaving even a small amount of moisture behind is the most common mistake. This moisture will rapidly form a new, hard layer of ice as the freezer cools down, defeating the purpose of the defrost and requiring you to repeat the process sooner.

Making the Right Choice for Your Goal

Your immediate actions should be based on the current state of your freezer, while your long-term goal should always be prevention.

- If your primary focus is dealing with light, flaky frost: Your key action is routine maintenance with a soft cloth and a dedicated plastic scraper during periods of low lab activity.

- If your primary focus is removing significant ice that affects the door seal: Your only option is to plan and execute a full system defrost, prioritizing the safe relocation of your samples to a backup unit.

- If your primary focus is long-term reliability and efficiency: Your goal is to implement strict lab protocols, including an inventory system to minimize door opening times and regular gasket inspections to stop moisture at the source.

By mastering both removal techniques and preventative strategies, you shift from reacting to problems to ensuring the consistent, reliable performance of your cold storage environment.

Summary Table:

| Frost Severity | Recommended Method | Key Tools | Primary Goal |

|---|---|---|---|

| Minor, Routine Buildup | Wipe or gently scrape | Soft cloth, plastic scraper | Maintain efficiency, prevent ice growth |

| Significant Ice (affects door/seal) | Full System Defrost | Backup freezer, absorbent pads, cloths | Restore performance, protect samples |

Ensure the longevity and reliability of your lab's cold storage with KINTEK.

Frost in your Ultra-Low Temperature Freezers is more than an inconvenience—it's a direct threat to your valuable samples and equipment efficiency. At KINTEK, we specialize in providing the high-quality lab equipment and consumables you need to maintain optimal conditions.

Our experts can help you select the right ULT freezers and implement preventative maintenance protocols to minimize frost buildup. Don't let frost compromise your research.

Contact our team today for a consultation on protecting your laboratory investments.

Visual Guide

Related Products

- 158L Precision Vertical Ultra Low Freezer for Laboratory Applications

- 708L Ultra Low Temperature Freezer High Performance Laboratory Freezer

- 408L Advanced Vertical Laboratory Ultra Low Temperature Freezer for Critical Research Material Preservation

- 308L Precision Ultra Low Temperature Freezer for Laboratory Applications

- 28L Compact Upright Ultra Low Temperature Freezer for Laboratory

People Also Ask

- What is convection-based cooling in ultra-low temperature freezers? Achieve Superior Temperature Stability for Your Samples

- How do ultra-low temperature freezers work? Unlocking the Secrets of -86°C Sample Preservation

- Why are ULT freezers considered vital equipment in labs? Ensuring Uncompromised Sample Integrity for Critical Research

- What are the different types of ultra-low temperature freezers available? Choose the Right ULT Freezer for Your Lab

- How are advancements in compressor technology and refrigerant fluids improving ULT freezers? Boost Efficiency & Cut Costs