At their core, advancements in compressor technology and refrigerant fluids are making ultra-low temperature (ULT) freezers significantly more energy-efficient and environmentally sustainable. This is primarily achieved by replacing older, high-impact greenhouse gas refrigerants with natural hydrocarbons and pairing them with smarter, microprocessor-controlled compressor systems that optimize performance and reduce waste.

The central shift is away from inefficient, environmentally damaging CFC/HFC refrigerants toward natural hydrocarbon (HC) fluids. When combined with intelligent compressor management, this change dramatically lowers energy consumption, reduces operating costs, and minimizes the freezer's carbon footprint.

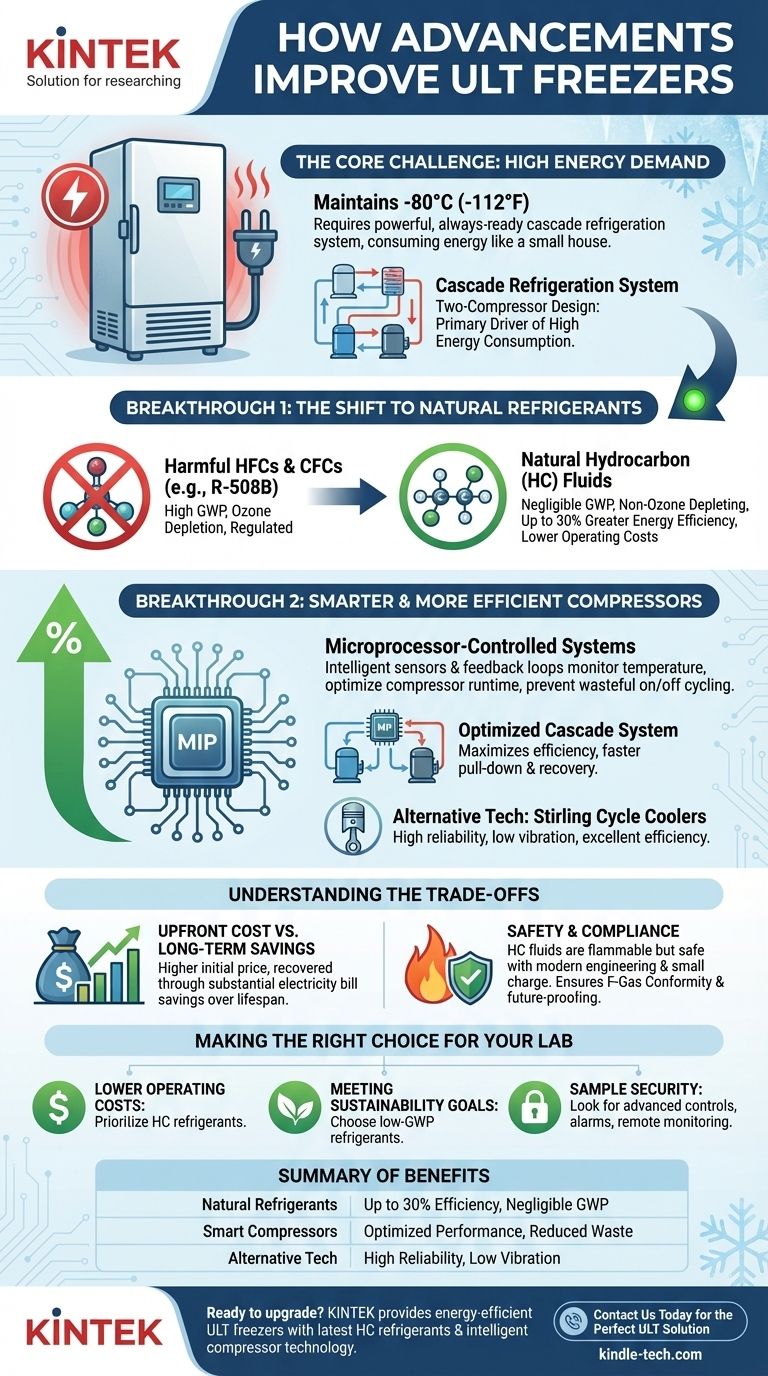

The Core Challenge: The High Energy Demand of ULT Freezers

To appreciate the recent improvements, we must first understand why ULT freezers are so power-intensive. The fundamental challenge is maintaining extreme temperatures reliably.

Why ULTs Consume So Much Power

A standard ULT freezer must hold its contents at temperatures around -80°C (-112°F). Maintaining this deep freeze requires a powerful and constantly ready refrigeration system, which can consume as much energy as a small house.

The Cascade Refrigeration System

Most ULT freezers use a cascade refrigeration system to achieve these temperatures. This is essentially two refrigeration systems working in tandem. The first stage cools the second, allowing the second stage to reach a much lower temperature than a single system could alone. While effective, this two-compressor design is a primary driver of high energy consumption.

Breakthrough 1: The Shift to Natural Refrigerants

The single biggest improvement in modern ULT freezers has come from changing the chemical fluids used to create the cold.

Moving Beyond Harmful HFCs and CFCs

Legacy freezers relied on chlorofluorocarbon (CFC) and hydrofluorocarbon (HFC) refrigerants, such as R-508B. These are potent greenhouse gases with high Global Warming Potential (GWP), and their production is now heavily regulated or phased out under international agreements.

The Rise of Hydrocarbon (HC) Fluids

Modern, energy-efficient freezers now use natural hydrocarbon (HC) refrigerants, typically a mixture of ethane and propane. These fluids are naturally occurring, have a negligible GWP, and are not ozone-depleting.

The Impact: Up to 30% Greater Efficiency

Beyond their environmental benefits, HC refrigerants are thermodynamically superior for this application. A system using natural hydrocarbon refrigerants can be up to 30% more energy-efficient than an older system using CFC/HFC fluids, leading to a direct and significant reduction in daily operating costs.

Breakthrough 2: Smarter and More Efficient Compressors

The mechanical systems are also evolving. Raw power is being replaced with intelligent control to minimize waste and improve performance.

The Role of Microprocessor Controls

Modern ULT freezers are governed by microprocessor-controlled systems. These onboard computers use sensors and feedback loops to monitor the internal temperature precisely. They run the compressors only when necessary, preventing the wasteful "on/off" cycling common in older designs.

Optimizing the Cascade System

This intelligent control is especially critical in a cascade system. The microprocessor can manage the two refrigeration circuits independently, ensuring they work in harmony for maximum efficiency rather than running at full power unnecessarily. This also contributes to faster temperature pull-down and recovery after a door opening.

Alternative Technologies: The Stirling Cycle

While less common, some manufacturers use Stirling cycle coolers instead of traditional compressors. These systems use a sealed amount of gas (like helium) and a piston-based mechanism to move heat. They are known for high reliability, low vibration, and excellent energy efficiency, representing another path toward a more sustainable ULT freezer.

Understanding the Trade-offs

While the benefits are clear, adopting this new technology requires awareness of the practical considerations.

Upfront Cost vs. Long-Term Savings

Freezers with hydrocarbon refrigerants and advanced microprocessor controls often have a higher initial purchase price. However, this cost is typically recovered over the freezer's lifespan through substantial savings on electricity bills.

Safety of Hydrocarbon Refrigerants

Hydrocarbon fluids like propane and ethane are flammable. While this presents a theoretical risk, modern freezers are engineered with very small charge volumes and robust safety features to mitigate this, making them safe for laboratory use when installed and maintained correctly.

Ensuring F-Gas Conformity

Regulations (like the F-Gas rules in Europe) restrict the use of high-GWP fluorinated gases. Choosing a freezer with natural HC refrigerants ensures compliance with current and future environmental standards, protecting your investment from becoming obsolete.

Making the Right Choice for Your Lab

Selecting a freezer requires balancing your operational needs with budget and sustainability goals.

- If your primary focus is lowering operating costs: Prioritize models that explicitly use natural hydrocarbon (HC) refrigerants for their proven energy efficiency.

- If your primary focus is meeting sustainability goals: Choose a freezer with low-GWP refrigerants to minimize your lab's carbon footprint and ensure long-term regulatory compliance.

- If your primary focus is sample security: Look for an integrated system with advanced microprocessor controls, robust alarm features, and remote monitoring capabilities to protect your valuable materials.

Ultimately, understanding the interplay between modern refrigerants and intelligent compressors empowers you to select a ULT freezer that is not only powerful and reliable but also cost-effective and environmentally responsible.

Summary Table:

| Advancement | Key Feature | Primary Benefit |

|---|---|---|

| Natural Refrigerants | Hydrocarbon (HC) fluids like propane/ethane | Up to 30% greater energy efficiency, negligible GWP |

| Smart Compressors | Microprocessor-controlled cascade systems | Optimized performance, reduced energy waste, faster recovery |

| Alternative Tech | Stirling cycle coolers | High reliability, low vibration, excellent efficiency |

Ready to upgrade your lab's efficiency and sustainability?

KINTEK specializes in providing state-of-the-art laboratory equipment, including energy-efficient ultra-low temperature freezers that utilize the latest hydrocarbon refrigerants and intelligent compressor technology. By partnering with us, you can significantly reduce your operating costs, ensure compliance with environmental regulations, and protect your valuable samples with reliable, advanced cooling systems.

Contact us today to find the perfect ULT freezer solution for your laboratory needs.

Visual Guide

Related Products

- 158L Precision Vertical Ultra Low Freezer for Laboratory Applications

- 28L Compact Upright Ultra Low Temperature Freezer for Laboratory

- 108L Vertical Ultra Low Temperature ULT Freezer

- 508L Advanced Vertical Ultra Low Temperature Freezer for Critical Laboratory Storage

- 308L Precision Ultra Low Temperature Freezer for Laboratory Applications

People Also Ask

- What is convection-based cooling in ultra-low temperature freezers? Achieve Superior Temperature Stability for Your Samples

- How should frost be removed from Ultra-Low Temperature Freezers? Protect Your Samples and Equipment

- Why are ultra-low temperature freezers important in scientific research? Ensure Sample Integrity and Reproducibility

- How do ultra-low temperature freezers work? Unlocking the Secrets of -86°C Sample Preservation

- What types of materials are commonly stored in ultra low temperature freezers? Preserving Cells, Vaccines & Biomolecules