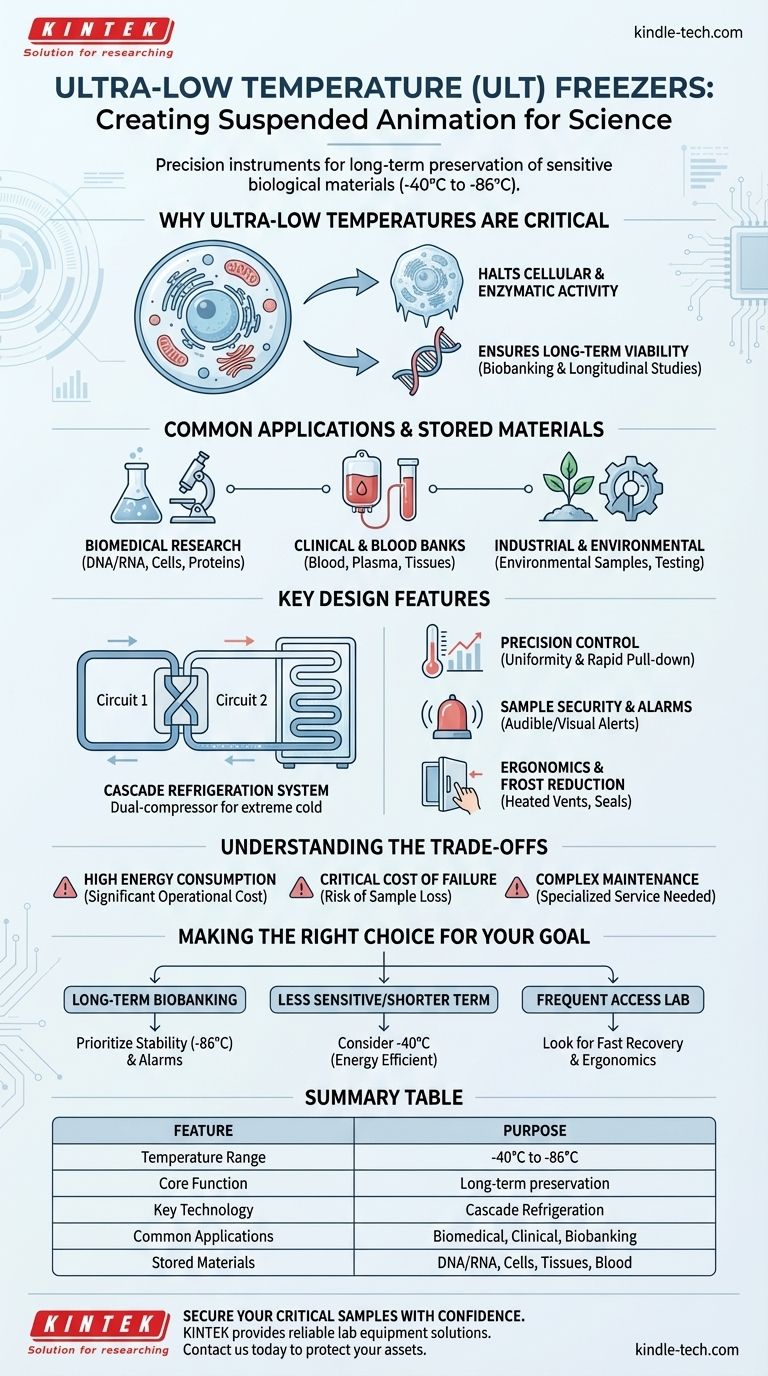

At their core, ultra-low temperature (ULT) freezers are precision instruments designed for the long-term preservation of sensitive biological materials. They create an extremely stable, cold environment, typically between -40°C and -86°C, which effectively halts the biological and chemical processes that cause samples to degrade over time. This ensures the integrity and viability of invaluable assets for research, clinical, and industrial applications.

The purpose of a ULT freezer isn't just to be extremely cold; it's to create a state of suspended animation for biological samples. By stopping molecular activity, it preserves the exact state of a sample for years, protecting irreplaceable data and materials.

Why Ultra-Low Temperatures Are Critical

Standard freezers are insufficient for long-term biological storage because significant degradation can still occur. ULT freezers solve this by creating an environment where biological and chemical activity virtually ceases.

Halting Cellular and Enzymatic Activity

At temperatures approaching -86°C, the molecular motion within a sample slows dramatically.

This prevents enzyme denaturation and other destructive chemical reactions that would otherwise compromise the sample's structure and function. It effectively freezes the material in time.

Ensuring Long-Term Viability

For many applications, samples must be stored for years or even decades.

This is essential for longitudinal research studies, where samples are collected over a long period, and for biobanking, which requires the stable archiving of materials like tissues, DNA, and plasma.

Common Applications and Stored Materials

The need to preserve high-value biologicals makes ULT freezers essential in a wide range of scientific and medical fields.

Biomedical and Pharmaceutical Research

This is the most common use case. Research universities, medical centers, and biotech companies rely on ULT freezers to store a variety of critical samples.

These include DNA/RNA, proteins, cells, tissues, and vaccines. The stability provided is crucial for the validity of experimental results.

Clinical, Forensic, and Blood Banks

Hospitals and clinical laboratories use these freezers for the long-term storage of patient samples.

Materials like blood, plasma, and autopsy materials are kept for diagnostic testing or forensic analysis, where sample integrity is paramount.

Industrial and Environmental Use

Beyond medicine, ULT freezers are used for specialized industrial purposes.

This can include testing product reliability under extreme cold to simulate arctic conditions or preserving delicate plant, insect, or bacterial samples for environmental research.

Key Design Features of a ULT Freezer

Achieving and maintaining -86°C requires specialized engineering that goes far beyond a typical refrigeration unit.

The Cascade Refrigeration System

The core technology is a cascade system, which uses two separate refrigeration circuits.

The first circuit cools the second, allowing the second circuit to reach a much lower temperature than a single compressor could alone. This multi-stage process is how ULT freezers efficiently achieve such extreme cold.

Precision Control and Uniformity

A ULT freezer must maintain its set temperature with extreme accuracy.

Key features include rapid temperature pull-down after a door opening and excellent temperature homogeneity, ensuring samples in every corner of the freezer are held at the correct temperature.

Sample Security and Alarms

The value of the stored contents is often immeasurable.

Because of this, ULT freezers are equipped with robust visual and audible alarms that trigger if the temperature deviates from the set point, alerting staff to potential failures before samples are compromised.

Ergonomics and Frost Reduction

Practical design is also critical for daily lab use.

Features like heated pressure release valves make the door easier to open, while advanced gasket and insulation systems are designed to reduce frost formation, which can damage samples and hinder freezer performance.

Understanding the Trade-offs

While indispensable, operating a ULT freezer involves significant considerations that must be managed.

High Energy Consumption

Maintaining a temperature gradient of over 100°C from the ambient room temperature requires a substantial amount of energy. The cascade compressor systems are powerful and represent a major operational cost for any facility.

The Critical Cost of Failure

A freezer malfunction can be catastrophic, potentially resulting in the loss of years of research or irreplaceable clinical samples. This high risk necessitates rigorous monitoring, reliable alarm systems, and often, backup power and secondary freezer plans.

Maintenance and Complexity

The dual-compressor cascade system is more complex than standard refrigeration units. It requires specialized technicians for service and preventative maintenance to ensure long-term reliability and prevent costly downtime.

Making the Right Choice for Your Goal

Selecting the appropriate ULT freezer depends entirely on the sensitivity of your samples and your operational needs.

- If your primary focus is long-term biobanking (DNA, cells, tissues): Prioritize a freezer with maximum temperature stability at -86°C and robust, networked alarm systems to guarantee sample integrity over decades.

- If your primary focus is storing less sensitive reagents or for shorter terms: A -40°C model may provide sufficient protection while being a more energy-efficient and cost-effective solution.

- If your primary focus is frequent access in a busy lab: Look for models with superior temperature recovery rates after door openings and ergonomic features that minimize frost.

Ultimately, a ULT freezer is a critical investment in the long-term security and viability of your most valuable biological assets.

Summary Table:

| Feature | Purpose |

|---|---|

| Temperature Range | -40°C to -86°C |

| Core Function | Long-term preservation of biological samples |

| Key Technology | Cascade Refrigeration System |

| Common Applications | Biomedical research, clinical storage, biobanking |

| Stored Materials | DNA/RNA, proteins, cells, tissues, blood, vaccines |

Secure Your Critical Samples with Confidence

Your research and clinical samples are invaluable. Protecting them requires reliable, high-performance equipment. KINTEK specializes in providing lab equipment and consumables, including ultra-low temperature freezers, to meet the precise needs of laboratories.

We understand that your work depends on the integrity of your samples. Let us help you find the right preservation solution to ensure their long-term viability and security.

Contact us today to discuss your specific requirements and ensure your most valuable assets are protected. Get in touch with our experts

Visual Guide

Related Products

- 58L Precision Laboratory Ultra Low Temperature Upright Freezer for Critical Sample Storage

- 708L Ultra Low Temperature Freezer High Performance Laboratory Freezer

- 208L Advanced Precision Laboratory Ultra Low Temperature Freezer for Cold Storage

- 608L Essential Laboratory Ultra Low Temperature Freezer For Critical Sample Preservation

- 808L Precision Laboratory Vertical Ultra Low Temperature Freezer

People Also Ask

- How does fast temperature recovery benefit ultra-low freezers? Protect Sample Integrity and Lab Efficiency

- What features do ultra-low temperature freezers typically include? Ensuring Absolute Sample Security

- What temperature ranges are typically associated with ultra-low temperature freezers? Preserve Samples from -40°C to -86°C

- What is the temperature control capability of ultra-low freezers? Precise Stability Down to -86°C

- How do ultra-low temperature freezers achieve such low temperatures? The Science Behind -80°C Cooling