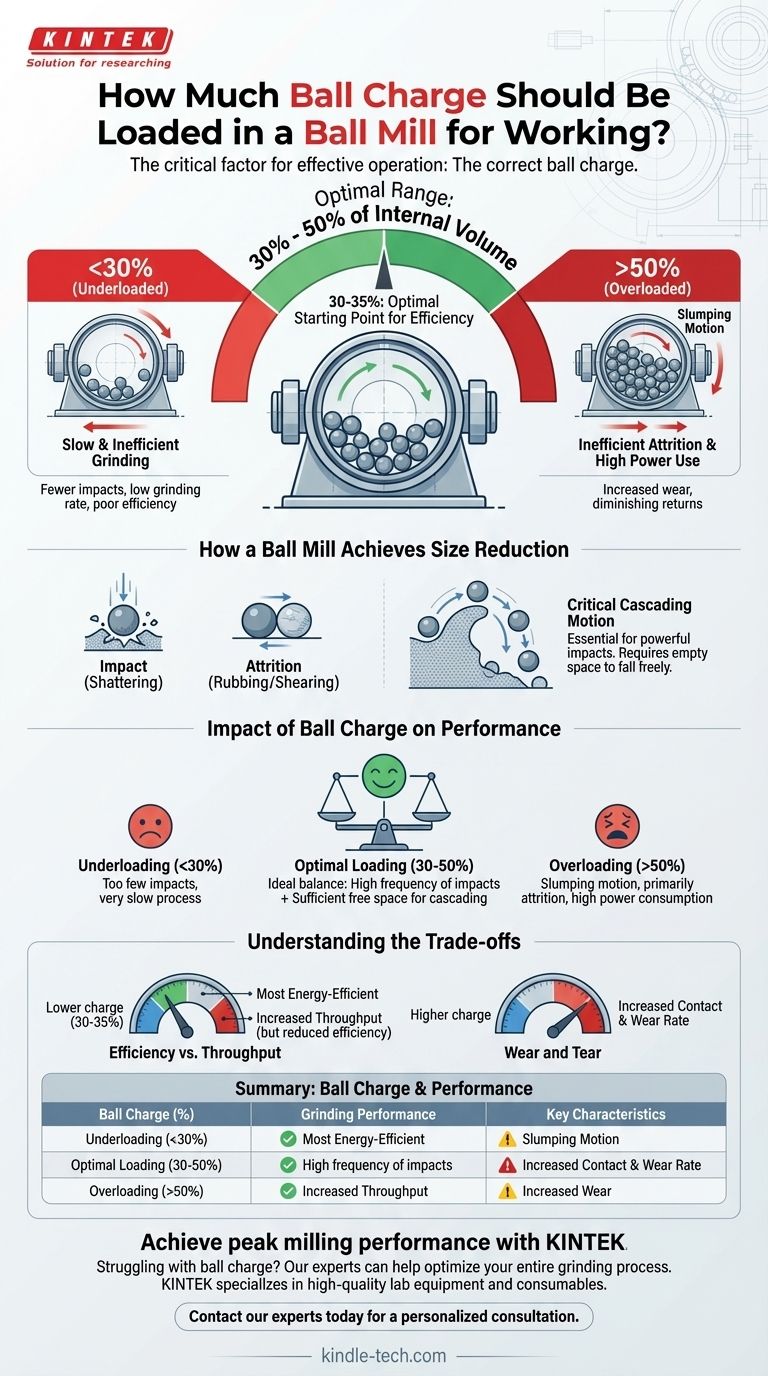

The correct ball charge is a critical factor for the effective operation of a ball mill. As a general rule, the grinding media (the balls) should occupy between 30% and 50% of the internal volume of the mill. For most applications focused on efficiency, a charge of 30% to 35% is considered the optimal starting point.

The goal is not simply to fill the mill, but to create the ideal conditions for grinding. The ball charge must be low enough to allow the balls to fall and impact the material, but high enough to ensure a sufficient number of grinding events occur with each rotation.

How a Ball Mill Achieves Size Reduction

To understand the correct ball charge, you must first understand the mechanism of the mill itself. The process relies on a specific type of motion to be effective.

The Role of Impact and Attrition

A ball mill grinds material using two primary forces: impact and attrition. Impact occurs when the balls fall from a height and strike the material, shattering it. Attrition is the rubbing and shearing action that happens as balls slide against each other and the mill liner.

The Critical "Cascading" Motion

As the mill rotates, the balls are carried up the side of the shell. The most effective grinding happens when these balls reach a certain height and then tumble and fall in a "cascading" motion, creating powerful impacts on the material below. This cascading is the engine of the size reduction process.

Why Free Space is Essential

This cascading action requires empty space within the mill. The balls need room to be lifted and, crucially, room to fall freely. Without this space, the primary force of impact is lost, severely hindering the mill's performance.

The Impact of Ball Charge on Performance

The percentage of the mill you fill with balls directly controls the grinding dynamics. Deviating from the optimal range has significant negative consequences.

Underloading (<30%)

If the ball charge is too low, there are simply not enough grinding media to work effectively. Fewer impacts occur per revolution, leading to a very slow and inefficient grinding process. The material may not be ground to the desired fineness in a reasonable amount of time.

Optimal Loading (30-50%)

Within this range, there is an ideal balance. The charge is dense enough to provide a high frequency of impacts, while still leaving enough void space for the balls to cascade properly. This maximizes the impact energy delivered to the material per unit of power consumed.

Overloading (>50%)

When the mill is overcharged, the balls have no room to fall. Instead of cascading, the charge tends to "slump", where the balls just roll over each other with very little impact. The primary grinding action shifts to inefficient attrition, power consumption increases dramatically, and the overall grinding rate can actually decrease.

Understanding the Trade-offs

Choosing the exact percentage within the 30-50% range involves balancing competing goals.

Efficiency vs. Throughput

A lower charge (around 30-35%) is often the most energy-efficient, producing the most ground product per kilowatt-hour. Pushing the charge higher (towards 45%) might increase throughput (tons per hour) to a point, but almost always at the cost of reduced energy efficiency.

Wear and Tear

A higher ball charge increases contact between the balls and the mill liners, which can accelerate the rate of wear. This leads to higher maintenance costs and more frequent replacement of both the grinding media and the liners.

Ball Size and Material

The optimal charge can also be influenced by the size of the balls and the hardness of the material being ground. Larger balls for coarser feed might operate better at a slightly different charge than smaller balls used for fine grinding.

Determining the Right Ball Load for Your Mill

There is no single magic number, but there are clear guidelines for finding the right charge for your specific objective.

- If your primary focus is maximum energy efficiency: Start with a ball charge at the lower end of the range, around 30-35% of the mill's internal volume.

- If your primary focus is maximizing throughput: You can experiment with a higher charge, approaching 40-45%, but monitor your power draw and product fineness closely to find the point of diminishing returns.

- If you are starting a new process or are unsure: A conservative charge of 35% is a safe and effective starting point from which you can make small adjustments.

Ultimately, treating the ball charge as a key operational variable to be optimized—not a fixed constant—is the path to mastering your milling process.

Summary Table:

| Ball Charge (% of Mill Volume) | Grinding Performance | Key Characteristics |

|---|---|---|

| < 30% (Underloaded) | Slow & Inefficient | Fewer impacts, low grinding rate, poor efficiency. |

| 30% - 50% (Optimal Range) | Highly Effective | Balanced impact & cascading motion; peak efficiency. |

| > 50% (Overloaded) | Inefficient & Damaging | Slumping motion, high power use, increased wear. |

Achieve peak milling performance with KINTEK.

Struggling to find the right ball charge for your specific material and throughput goals? Our experts can help you optimize your entire grinding process. KINTEK specializes in high-quality lab equipment and consumables, providing the right solutions for your laboratory's milling and size reduction challenges.

Contact our experts today for a personalized consultation and discover how we can enhance your lab's efficiency and productivity.

Visual Guide

Related Products

- Laboratory Jar Ball Mill with Alumina Zirconia Grinding Jar and Balls

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What is the primary function of a planetary ball mill? Mastering SiC/Al Composite Mixing for Homogeneity

- What is the primary function of a planetary ball mill in ODS steel prep? Achieving Nanoscale Mechanical Alloying

- What is the function of a planetary ball mill in MAX phase powder preparation? Unlock High-Purity Atomic Homogeneity

- What is the speed range of a ball mill? Find Your Optimal Grinding Efficiency

- What are the unique energy transfer characteristics of PBM? Master Complex Heterocyclic Synthesis