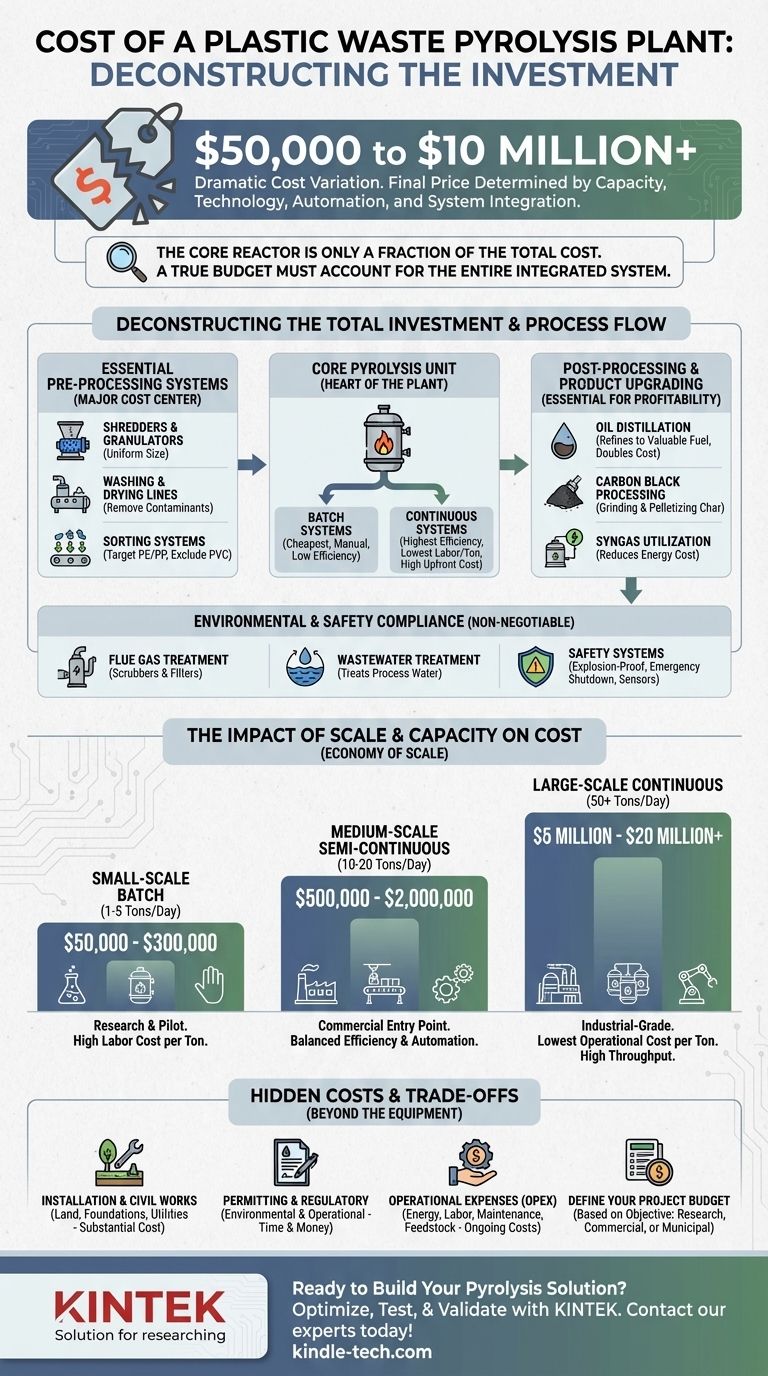

The cost of a plastic pyrolysis plant varies dramatically, from as little as $50,000 for a small-scale batch system to well over $10 million for a large, automated industrial facility. The final price is not determined by a single piece of equipment, but by the plant's processing capacity, the type of technology used (batch vs. continuous), the level of automation, and the required pre- and post-processing systems needed to handle specific types of plastic waste and produce valuable end-products.

The sticker price of the pyrolysis reactor is only a fraction of the total project cost. A true budget must account for the entire system—from waste sorting and preparation to product purification and environmental compliance—as these ancillary systems often represent the majority of the total investment.

Deconstructing the Total Investment

A common mistake is to focus solely on the core pyrolysis reactor. A functional and profitable plant is an integrated system where each component has a significant impact on both upfront capital expenditure (CAPEX) and long-term operational expenditure (OPEX).

Core Pyrolysis Unit

This is the heart of the plant where plastic is heated in an oxygen-free environment. The primary cost driver here is the operational method and capacity. Batch systems are the cheapest, requiring manual loading and unloading. Continuous systems offer the highest efficiency and lowest labor cost per ton but have a much higher initial price due to their complexity and automation.

Essential Pre-Processing Systems

Raw plastic waste is rarely suitable for direct pyrolysis. It must be prepared, and this preparation stage is a major cost center. Key systems include:

- Shredders and Granulators: To reduce the plastic to a uniform size for efficient heating.

- Washing and Drying Lines: To remove contaminants (dirt, paper, metal) and moisture, which is critical for producing high-quality oil.

- Sorting Systems: For plants handling mixed waste, optical sorters or other technologies may be needed to separate desired plastics (like PE and PP) from undesirable ones (like PVC, which produces corrosive acids).

Post-Processing and Product Upgrading

The raw output of pyrolysis—a heavy, crude-like oil, a carbon-rich solid (char), and a non-condensable gas (syngas)—has limited value. Upgrading these products is essential for profitability but adds significant cost.

- Oil Distillation: A fractional distillation column can refine the raw pyrolysis oil into more valuable fractions, such as a diesel-like fuel. This step can easily double the cost of the core plant.

- Carbon Black Processing: The solid char can be processed into a usable "carbon black" product, requiring grinding, pelletizing, and packaging equipment.

- Syngas Utilization: The produced gas can be used to help heat the reactor, reducing external energy costs. This requires specialized burners and gas handling systems.

Environmental and Safety Compliance

This is a non-negotiable cost. Modern plants must meet strict environmental regulations, which requires significant investment in control technologies.

- Flue Gas Treatment: Scrubbers and filters are needed to clean the exhaust from the heating system before it's released into the atmosphere.

- Wastewater Treatment: Water used for cooling or washing plastic must be treated before discharge.

- Safety Systems: Explosion-proof motors, emergency shutdown systems, and extensive sensor networks are critical for safe operation and add to the overall cost.

The Impact of Scale and Capacity on Cost

The "economy of scale" principle applies directly to pyrolysis plants. While larger plants cost more upfront, their cost per ton of processing capacity is significantly lower.

Small-Scale Batch Plants (1-5 Tons/Day)

These systems typically range from $50,000 to $300,000. They are best suited for research, pilot projects, or small, decentralized operations with a clean and consistent feedstock. Their main drawback is high labor cost per ton and lower overall efficiency.

Medium-Scale Semi-Continuous Plants (10-20 Tons/Day)

Expect costs in the range of $500,000 to $2 million. These plants represent a common entry point for commercial ventures. They offer better efficiency and more automation than batch systems and can be a good balance between upfront investment and operational output.

Large-Scale Continuous Plants (50+ Tons/Day)

These industrial-grade facilities typically start at $5 million and can easily exceed $20 million. They are designed for high-throughput, 24/7 operation and are integrated with advanced automation, sorting, and product upgrading. While the initial investment is immense, they offer the lowest operational cost per ton and are necessary for tackling municipal-level waste problems.

Understanding the Hidden Costs and Trade-offs

The equipment price list is just the beginning. Several other significant expenses must be factored into any realistic budget.

Installation and Civil Works

The cost of land, site preparation, concrete foundations, buildings to house the equipment, and utility connections (power, water) can be a substantial portion of the total project budget, sometimes rivaling the cost of the equipment itself.

Permitting and Regulatory Hurdles

Securing environmental and operational permits can be a complex, time-consuming, and expensive process. This often requires hiring environmental consultants, conducting impact studies, and paying legal fees, which can add tens or even hundreds of thousands of dollars to the project cost before a single piece of equipment is ordered.

Operational Expenses (OPEX)

A "cheap" plant may have cripplingly high operational costs. Key OPEX factors include:

- Energy: The energy required to heat the reactor is a primary cost. Using the plant's own syngas can offset this, but an external fuel source (like natural gas) is often needed, especially for startup.

- Labor: Less automated plants require more staff for loading, monitoring, and maintenance.

- Maintenance: Pyrolysis is a harsh industrial process. A budget for spare parts, repairs, and regular downtime for cleaning is essential.

- Feedstock Sourcing: The cost of acquiring and transporting the plastic waste to your facility is a fundamental business expense.

How to Define Your Project Budget

Your budget should be determined by your project's primary objective.

- If your primary focus is research or small-scale demonstration: Opt for a flexible batch system to minimize upfront capital risk while you validate your process and business model.

- If your primary focus is establishing a profitable commercial business: Your model must include robust pre-processing and oil upgrading systems, so budget for a medium-scale, semi-continuous plant with a clear path for expansion.

- If your primary focus is large-scale municipal waste management: Plan for a major, multi-million dollar investment in a fully continuous, highly automated plant with comprehensive environmental controls.

A successful pyrolysis project begins not with a price tag, but with a thorough understanding of the complete system required to achieve your specific goals.

Summary Table:

| Plant Scale | Capacity (Tons/Day) | Typical Cost Range | Key Characteristics |

|---|---|---|---|

| Small-Scale Batch | 1-5 | $50,000 - $300,000 | Manual operation, ideal for research/pilot projects |

| Medium-Scale Semi-Continuous | 10-20 | $500,000 - $2,000,000 | Balanced automation, commercial viability |

| Large-Scale Continuous | 50+ | $5,000,000 - $20,000,000+ | Full automation, municipal-level waste processing |

Ready to Build Your Pyrolysis Solution?

KINTEK specializes in providing comprehensive laboratory equipment and consumables for waste-to-energy research and development. Whether you're starting with a small-scale pilot or scaling up to commercial production, our expertise can help you:

- Optimize your process with reliable lab-scale pyrolysis systems

- Test feedstock quality with precise analytical equipment

- Validate end-products using our range of laboratory instruments

Let us support your plastic waste pyrolysis project with the right equipment and consumables for accurate testing and successful scale-up.

Contact our experts today to discuss your specific requirements and get a tailored solution!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Twin Screw Extruder Plastic Granulation Machine

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Test Sieves and Sieving Machines

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- Why KBr is used to prepare samples for FTIR analysis? Unlock Clear, High-Quality Spectra

- What materials are used in electron beam evaporation? Master High-Purity Thin Film Deposition

- What are the benefits of bio-oil pyrolysis? Turn Waste into Renewable Energy

- What is conventional sintering? Transform Powder into Dense, High-Strength Materials

- Which is a disadvantage of the carburizing process? High Costs, Complex Control, and Post-Processing Demands

- What are 3 advantages of an electric furnace? Lower Cost, Safer Operation & Universal Availability

- What are the disadvantages of hardening? The Critical Trade-offs of Increased Brittleness and Stress

- What is the basic of brazing? A Guide to Strong, Low-Heat Metal Joining