The power required for a hammer mill is not a single number, but a range that spans from as little as 5 horsepower for small-scale or laboratory models to over 600 horsepower (450 kW) for large, industrial units used in bio-refining or high-volume feed milling. The final power consumption is a direct result of the material being ground, the desired final particle size, and the mill's specific design and throughput rate.

The most critical insight is that power consumption is not a fixed attribute of the mill itself, but a dynamic variable determined by the work it is being asked to do. Understanding the factors that drive power demand is essential for correctly sizing equipment, controlling operational costs, and optimizing your entire process.

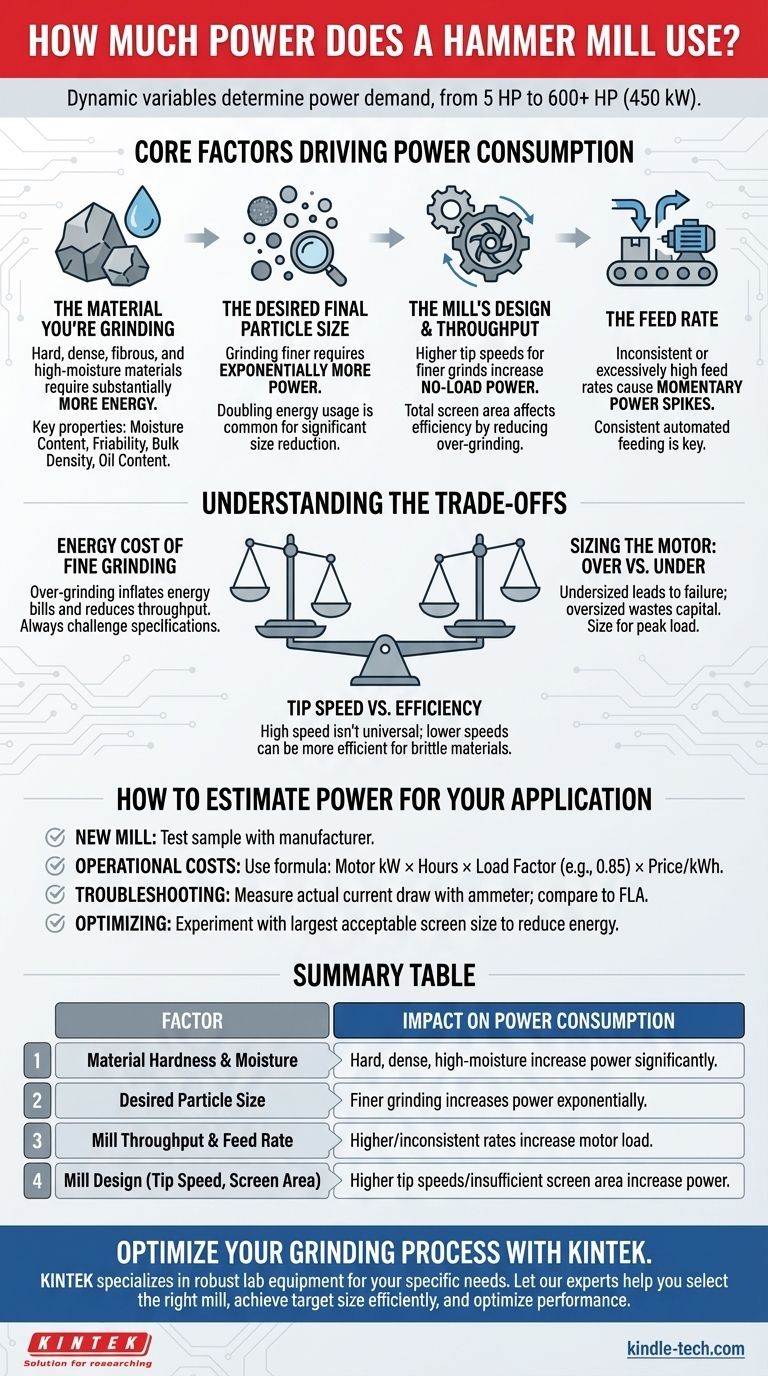

The Core Factors Driving Power Consumption

To accurately estimate power requirements, you must look beyond the mill's motor rating and analyze the specific application. The motor is sized to handle a potential load, but the actual power draw is determined by the task at hand.

The Material You're Grinding

The characteristics of the input material are the single most significant factor. Hard, dense, and fibrous materials require substantially more energy to break down than soft, friable ones.

Key properties include moisture content, friability (how easily it shatters), bulk density, and oil content. Grinding high-moisture corn, for example, will consume significantly more power than grinding dry, brittle barley.

The Desired Final Particle Size

The relationship between particle size and energy is not linear. Grinding to a finer particle size requires exponentially more power.

This is because you are creating a vastly larger total surface area. Reducing particle size from 800 microns to 400 microns can easily double your energy consumption per ton of product, as the material must spend more time in the grinding chamber being struck by the hammers.

The Mill's Design and Throughput

A mill's physical characteristics directly influence its efficiency and power needs. The rotor diameter and tip speed (the speed at which the hammer tips travel) are primary design factors.

Higher tip speeds generally lead to finer grinds and higher throughput but also increase no-load power draw and accelerate wear on hammers and screens. The total screen area also plays a role; more screen area allows for a more efficient evacuation of correctly sized particles, reducing the energy wasted on over-grinding.

The Feed Rate

How quickly you introduce material into the mill directly impacts the load on the motor. An inconsistent or excessively high feed rate can cause momentary power spikes, potentially tripping breakers.

A properly automated feed system that maintains a consistent motor load is key to both energy efficiency and maximizing the mill's throughput capacity.

Understanding the Trade-offs

Choosing and operating a hammer mill involves balancing competing goals. Focusing on one metric, like power, without considering the others can lead to poor outcomes.

The Energy Cost of Fine Grinding

A common and costly mistake is grinding material finer than the downstream process requires. This needlessly inflates energy bills and reduces overall throughput.

Always challenge the particle size specification. A slight increase in acceptable particle size is often the single biggest lever you can pull to reduce operational costs.

Sizing the Motor: Over vs. Under

An undersized motor is a critical failure point. It will constantly struggle, overheat, and eventually burn out or trip overload protection, causing costly downtime.

Conversely, a grossly oversized motor represents wasted capital expenditure and operates inefficiently at partial loads, slightly increasing energy cost per ton. The motor should be sized to handle the peak load of the most demanding material you plan to process.

Tip Speed vs. Efficiency

While high tip speeds can improve grinding action for some materials, they are not a universal solution. For brittle, easy-to-grind materials, a lower tip speed may be more energy-efficient and will always result in lower wear and maintenance costs. The optimal tip speed is material-dependent.

How to Estimate Power for Your Application

Use these guidelines to translate the principles above into a practical decision for your specific goal.

- If your primary focus is sizing a new mill: Do not guess. Provide a sample of your material to a manufacturer for testing. They can give you a precise recommendation based on your required throughput and target particle size.

- If your primary focus is estimating operational costs: Use the motor's power rating (in kW) as a starting point, but assume a load factor. A simple formula is:

Motor kW * Operating Hours * Load Factor (e.g., 0.85) * Price per kWh = Estimated Cost. - If your primary focus is troubleshooting power issues: Use a clamp-on ammeter to measure the actual current draw during operation. Compare this to the motor's Full Load Amps (FLA) rating on its nameplate to determine if it is overloaded.

- If your primary focus is optimizing an existing process: Experiment with the largest screen size (producing the coarsest particle) that is acceptable for your final product. This is your most powerful tool for reducing energy consumption.

By understanding these core principles, you can move from simply asking about power usage to engineering your grinding operation for maximum efficiency and reliability.

Summary Table:

| Factor | Impact on Power Consumption |

|---|---|

| Material Hardness & Moisture | Hard, dense, high-moisture materials require significantly more power. |

| Desired Particle Size | Grinding finer increases power exponentially due to greater surface area creation. |

| Mill Throughput & Feed Rate | Higher and inconsistent feed rates increase motor load and can cause power spikes. |

| Mill Design (Tip Speed, Screen Area) | Higher tip speeds and insufficient screen area can increase no-load power and over-grinding. |

Optimize your grinding process with the right equipment from KINTEK.

Understanding power consumption is crucial for controlling costs and maximizing efficiency. Whether you're in feed milling, bio-refining, or laboratory research, KINTEK specializes in providing robust and efficient lab equipment and consumables tailored to your specific material and throughput needs.

Let our experts help you:

- Select the correctly sized mill to avoid costly downtime from an undersized motor or inefficient oversizing.

- Achieve your target particle size with optimal energy efficiency, reducing your operational costs.

- Troubleshoot and optimize your existing setup for better performance and reliability.

Don't let power uncertainties hinder your productivity. Contact KINTEK today for a personalized consultation and discover how our solutions can enhance your laboratory's grinding operations.

Visual Guide

Related Products

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Single Horizontal Jar Mill

- Laboratory Four-Body Horizontal Jar Mill

- Laboratory Grinding Mill Mortar Grinder for Sample Preparation

People Also Ask

- What are the advantages of using a high-shear homogenizer for BED/GMA coatings? Achieve Superior Nano-Dispersion

- What are the factors that affect milling machine? Master the Trade-offs for Peak Performance

- Why is the wet milling mode preferred for Fe-Cr-Mo-C alloy powder? Ensure Data Integrity for Neutron Diffraction

- What is a colloidal mill also known as? Discover the Power of Rotor-Stator Mixers

- What does a grinder do in a laboratory? Achieve Homogeneous Sample Preparation for Accurate Analysis

- Why are high-power ultrasonic homogenizers essential for liquid metal nanodroplets? Overcome Surface Tension Barriers

- Why are different size balls used in ball mills? Optimize Grinding for Maximum Efficiency

- What role does a mechanical ball mill play in Al-Sn/Graphene production? Master Nano-Dispersion and Alloying