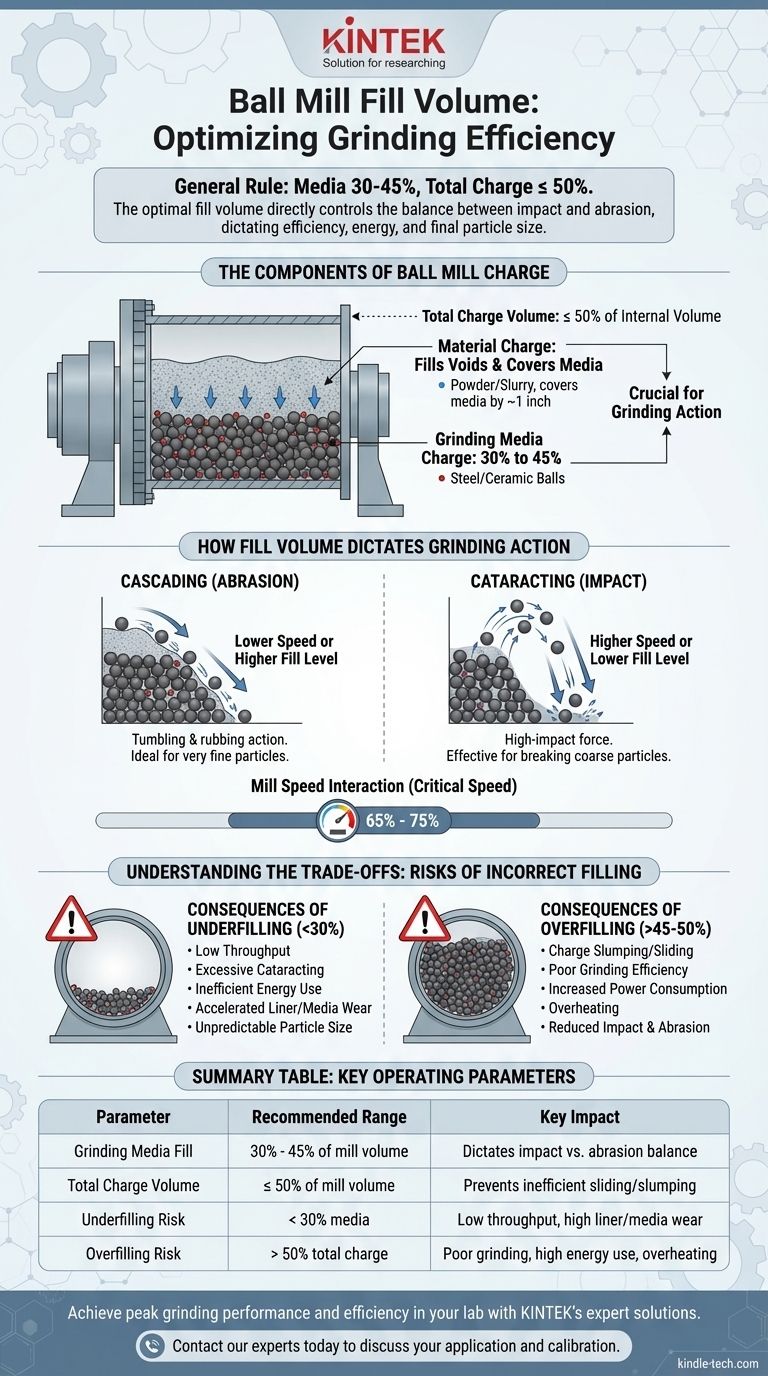

As a general rule, the grinding media should fill between 30% to 45% of the internal volume of the ball mill. The material being ground (the charge) then fills the void spaces between this media. The total volume of both media and material should not exceed 50% of the mill's capacity to allow for proper grinding action.

The optimal fill volume is not a single number but a critical operating parameter. It directly controls the balance between impact and abrasion, which in turn dictates grinding efficiency, energy consumption, and the final particle size of your product.

The Components of Ball Mill Charge

To understand the total fill volume, you must first distinguish between its two primary components: the grinding media and the material charge.

Grinding Media Charge

The grinding media (steel balls, ceramic balls, or rods) are the primary tools of comminution. The volume they occupy is the most critical variable.

This media charge is typically maintained between 30% and 45% of the mill's net internal volume. This range provides the space needed for the media to lift and fall effectively.

Material Charge

The material charge is the powder or slurry you intend to grind. Its volume is determined by the grinding media.

The material should completely fill the void space between the grinding balls and cover them by a small amount, roughly an inch. This ensures that grinding energy is transferred to the material, not wasted on media-on-media or media-on-liner contact.

Total Charge Volume

When combined, the total volume of media and material should ideally not surpass 50% of the mill's internal volume. Exceeding this severely hinders the grinding process.

How Fill Volume Dictates Grinding Action

The percentage of the mill you fill directly determines the mechanical action inside. This action is a function of both fill level and mill speed.

The Cascading vs. Cataracting Effect

At lower mill speeds or higher fill levels, the charge tends to cascade. The balls tumble down the face of the charge, creating a rubbing and abrasive action ideal for producing very fine particles.

At higher mill speeds or lower fill levels, the charge begins to cataract. The balls are thrown into the air and fall freely, creating a high-impact force that is effective for breaking down coarser particles quickly.

The Role of Mill Speed

Fill volume cannot be considered in isolation. It works in tandem with the mill's rotational speed, often expressed as a percentage of critical speed.

Critical speed is the theoretical speed at which the media would centrifuge, clinging to the mill liner and ceasing all grinding. Most mills operate between 65% and 75% of this speed. Adjusting the fill level allows you to fine-tune whether you get a cascading or cataracting effect within this optimal speed window.

Understanding the Trade-offs: The Risks of Incorrect Filling

Deviating from the optimal fill range introduces significant inefficiencies and risks to your operation and equipment.

Consequences of Underfilling

Underfilling the mill with media (below 30%) leaves too much empty space. This reduces the number of grinding events, drastically lowering throughput.

It also promotes excessive cataracting, causing the media to impact the mill liners directly. This leads to inefficient energy use, accelerated wear on both the media and the liners, and a less predictable particle size distribution.

Consequences of Overfilling

Overfilling the mill (above 45-50% total volume) is equally detrimental. The charge becomes too packed to lift and fall properly.

Instead of cascading or cataracting, the charge merely slumps or slides. This dampens impact and abrasion, leading to extremely poor grinding efficiency. Power consumption increases significantly without a corresponding increase in useful work, often leading to overheating.

Optimizing Your Mill Charge: A Practical Guide

The ideal charge volume is specific to your material, equipment, and production goals. Use the following principles as a starting point for optimization.

- If your primary focus is maximum throughput on coarse material: Start with a lower media charge (around 30-35%) and a speed in the higher end of the normal range (70-75% of critical speed) to encourage high-impact cataracting.

- If your primary focus is achieving a very fine final product: Use a higher media charge (around 40-45%) and a slightly lower speed (65-70% of critical speed) to maximize the abrasive action of cascading.

- If your primary focus is energy efficiency: Begin with a mid-range media charge (35-40%) and conduct tests. Measure power draw against product output to find the sweet spot that delivers your target particle size with the lowest specific energy consumption.

Ultimately, the ideal fill volume is found through careful, methodical testing and observation of your specific process.

Summary Table:

| Parameter | Recommended Range | Key Impact |

|---|---|---|

| Grinding Media Fill | 30% - 45% of mill volume | Dictates impact vs. abrasion balance |

| Total Charge Volume | ≤ 50% of mill volume | Prevents inefficient sliding/slumping |

| Underfilling Risk | < 30% media | Low throughput, high liner/media wear |

| Overfilling Risk | > 50% total charge | Poor grinding, high energy use, overheating |

Achieve peak grinding performance and efficiency in your lab. The correct ball mill fill volume is critical for your specific materials and goals. KINTEK specializes in lab equipment and consumables, providing expert solutions to optimize your milling process. Contact our experts today to discuss your application and ensure your equipment is calibrated for success!

Visual Guide

Related Products

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Mini Planetary Ball Mill Machine for Laboratory Milling

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- Liquid Nitrogen Cryogenic Grinder Mill Cryomill Airflow Ultrafine Pulverizer

People Also Ask

- What is wet grinding and dry grinding? Choose the Right Method for Your Materials

- Why is mechanochemical synthesis equipment essential for single-atom catalysts? Scale Your Production Efficiency

- What can a ball mill produce? Achieve Fine Powders and Slurries for Your Materials

- What kind of material is a hammer mill used for? Process Brittle, Dry, and Crystalline Materials Efficiently

- How do laboratory pulverizers contribute to finished Ag/Ce-Mn catalysts? Maximize Surface Area and Catalytic Activity

- Why are zirconia milling balls preferred for P2-type layered oxides? Ensure High Purity and Grinding Efficiency

- What is the primary role of a light ball mill? Optimize SiC/Cu-Al2O3 Composite Powder Homogeneity

- What is the significance of advanced stirring and mixing systems? Maximize Carbon Capture and Reaction Efficiency