Designing a pyrolysis reactor is a process of matching its physical configuration and operating parameters to your desired end product. There is no single "best" design; the optimal choice depends entirely on whether you aim to maximize the yield of biochar, bio-oil, or syngas. The reactor's core function is to control heat transfer and residence time in an oxygen-free environment, which dictates the final product slate.

The fundamental challenge in pyrolysis reactor design is not simply choosing a technology, but understanding how the method of heat transfer and feedstock processing time directly controls the outcome. Your target product—whether solid, liquid, or gas—must be the primary driver of every design decision.

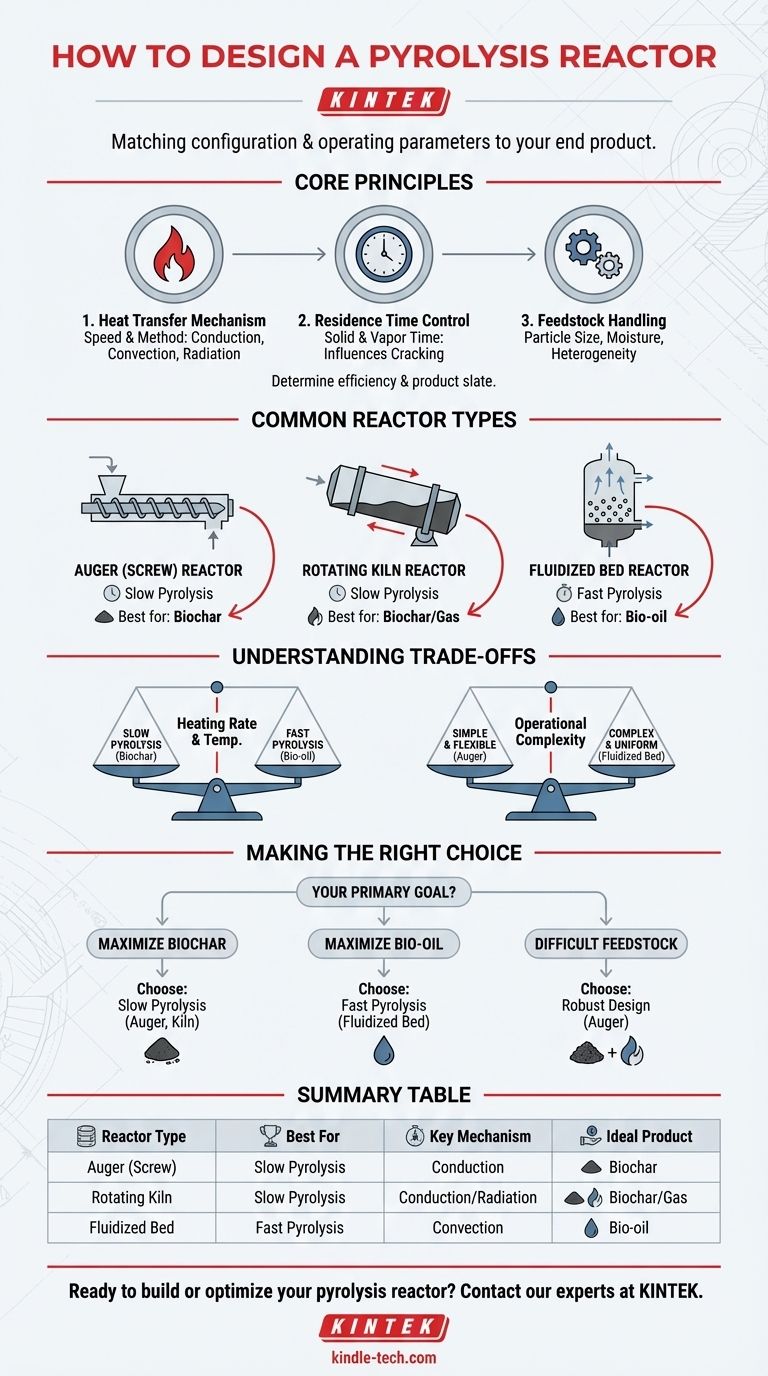

The Core Principles of Reactor Design

Before selecting a specific reactor type, it is crucial to understand the three principles that govern its performance. These principles determine how efficiently your feedstock is converted into your target product.

Principle 1: Heat Transfer Mechanism

The speed and method of heat transfer are the most critical factors in pyrolysis. Rapid heating favors the production of liquids (bio-oil), while slow heating maximizes solids (biochar).

Different reactors use different primary mechanisms: conduction (direct contact), convection (hot gases), or radiation. The choice of mechanism is a foundational design decision.

Principle 2: Residence Time Control

Residence time refers to how long the material stays in the heated zone of the reactor. There are two types to consider: solid residence time and vapor residence time.

Long solid residence times promote secondary cracking, leading to more biochar and gas. To maximize bio-oil, a short vapor residence time is essential to quickly remove and condense the valuable liquids before they break down further.

Principle 3: Feedstock Handling

The physical characteristics of your feedstock—such as particle size, moisture content, and heterogeneity—heavily influence reactor selection.

A design that works perfectly for fine, dry sawdust will fail with wet, bulky materials. The reactor's feeding and discharge systems must be matched to the material you intend to process.

Common Pyrolysis Reactor Types

Each reactor type is optimized for a different set of conditions and products. The choice among them represents the most significant step in the design process.

Auger (Screw) Reactors

An auger reactor uses a large screw to transport feedstock through a heated tube. Heat is transferred primarily through conduction from the reactor walls.

This design forces a relatively slow heating rate and long solid residence time, making it ideal for slow pyrolysis and maximizing biochar production. As noted in research, its mechanical robustness also makes it suitable for difficult or mixed feedstocks.

Rotating Kiln Reactors

This is a large, rotating cylinder set at a slight incline. Feedstock tumbles through as it rotates, ensuring good mixing and uniform heating.

Like auger reactors, kilns are typically used for slow pyrolysis. They are simple, reliable, and can handle large particle sizes, making them a common choice for industrial-scale biochar and gas production.

Fluidized Bed Reactors

In this design, an upward flow of hot carrier gas (like nitrogen) suspends the feedstock particles, causing them to behave like a fluid. This creates extremely high rates of heat transfer through convection.

Fluidized beds are the industry standard for fast pyrolysis. The rapid heating and very short vapor residence times (often less than two seconds) are ideal for maximizing bio-oil yields. However, they require a uniform, small particle size for the feedstock.

Understanding the Trade-offs

Designing a reactor is an exercise in balancing competing factors. A choice that improves one metric often compromises another.

Slow vs. Fast Pyrolysis

This is the central trade-off. Slow pyrolysis (low temperatures, long residence times) maximizes the solid biochar yield. This is achieved in reactors like augers and rotating kilns.

Fast pyrolysis (high temperatures, rapid heating, short residence times) maximizes the liquid bio-oil yield. This requires more complex reactors like fluidized beds.

Temperature and Heating Rate

These are your primary control levers. Low temperatures (350-550°C) and slow heating rates (<10°C/s) favor biochar. High temperatures (450-600°C) and extremely high heating rates (>100°C/s) are necessary for high bio-oil yields.

Operational Complexity vs. Feedstock Flexibility

Reactors like augers are mechanically simple and can handle a wide variety of feedstocks. However, their product output is limited primarily to biochar.

High-performance reactors like fluidized beds are more complex to operate and demand carefully prepared, uniform feedstock. The trade-off is their superior ability to produce high-value bio-oil.

Regulatory and Feasibility Hurdles

Beyond the technical design, practical implementation requires a feasibility study to assess feedstock availability. You must also engage with local authorities to ensure environmental compliance and obtain the necessary operating permits.

Making the Right Choice for Your Goal

Your reactor design must be a direct reflection of your primary objective. Use these guidelines to steer your decision.

- If your primary focus is maximizing biochar production: Choose a slow pyrolysis design like an auger or rotating kiln that allows for long solid residence times and slower heating rates.

- If your primary focus is maximizing bio-oil yield: You must select a fast pyrolysis reactor, such as a fluidized bed, that provides rapid heat transfer and short vapor residence times.

- If your primary focus is handling difficult or non-uniform feedstock: An auger reactor offers superior mechanical handling and robustness, though its output will be heavily weighted toward biochar.

A properly designed reactor is one where the technology is purposefully aligned with the desired chemical transformation.

Summary Table:

| Reactor Type | Best For | Key Mechanism | Ideal Product |

|---|---|---|---|

| Auger (Screw) | Slow Pyrolysis | Conduction | Biochar |

| Rotating Kiln | Slow Pyrolysis | Conduction/Radiation | Biochar/Gas |

| Fluidized Bed | Fast Pyrolysis | Convection | Bio-oil |

Ready to build or optimize your pyrolysis reactor? At KINTEK, we specialize in providing high-quality lab equipment and consumables tailored to your pyrolysis research and development needs. Whether you're focused on maximizing biochar, bio-oil, or syngas yields, our expertise in reactor design support, temperature control systems, and feedstock handling solutions can help you achieve precise, efficient, and scalable results. Contact our experts today to discuss how we can accelerate your pyrolysis projects!

Visual Guide

Related Products

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- What roles do autoclaves play in MFI zeolite synthesis? Master Hydrothermal Crystalline Growth

- What is the role of high-pressure reactors in the study of alloy oxidation? Essential Tools for Supercritical Research

- What is the function of a constant temperature hydrothermal reactor? Master Coal Fly Ash Activation

- Why are high-pressure autoclaves essential for preparing bio-based polyamide curing agents from dimeric acid?

- What is the purpose of using high-purity argon gas in a high-pressure reactor? Ensure Precise Corrosion Test Data