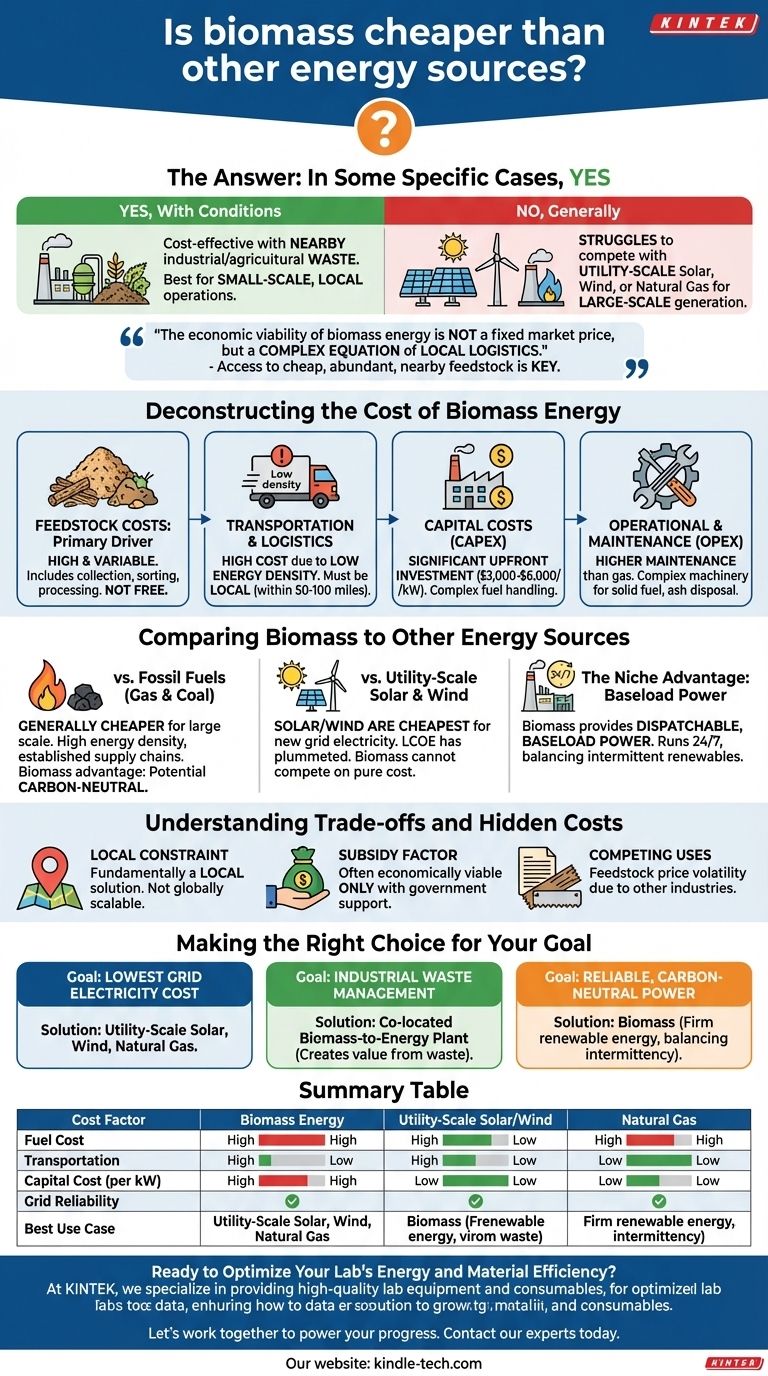

In some specific cases, yes, but it is a deeply misleading oversimplification to label biomass as universally "cheap." The cost of biomass energy is highly variable, depending almost entirely on the type of feedstock, its proximity to the power plant, and the scale of the operation. While it can be cost-effective when using nearby industrial or agricultural waste, it often struggles to compete on price with utility-scale solar, wind, or natural gas for large-scale electricity generation.

The economic viability of biomass energy is not a question of a fixed market price, but a complex equation of local logistics. Its cost-effectiveness is almost exclusively determined by access to a cheap, abundant, and nearby supply of feedstock.

Deconstructing the Cost of Biomass Energy

To understand if biomass is "cheaper," you must first break down its unique cost structure. Unlike solar or wind where the "fuel" is free, or natural gas where fuel is a globally traded commodity, biomass costs are hyper-localized.

Feedstock Costs: The Primary Driver

The single largest operational cost for a biomass plant is the feedstock—the organic material being burned. This can range from dedicated energy crops and wood pellets to agricultural residue and municipal solid waste.

"Waste" products are not free. They require significant investment in collection, sorting, and processing before they can be used as fuel, adding a substantial cost that is often overlooked.

Transportation and Logistics

Biomass has a low energy density compared to fossil fuels. This means you have to transport a much greater volume and weight of material to generate the same amount of energy, making transportation a major and often prohibitive expense.

For this reason, successful biomass projects are almost always located immediately next to their fuel source, such as a paper mill using its own wood waste or a farm using crop residue.

Capital Costs (CAPEX): Building the Plant

The upfront investment to build a biomass power plant is significant. Capital costs can range from $3,000 to over $6,000 per kilowatt (kW) of capacity.

This is often more expensive than a comparable natural gas plant but can be in a similar range to other renewable technologies. The complexity of the fuel handling and combustion systems contributes heavily to this cost.

Operational and Maintenance Costs (OPEX)

Beyond fuel, biomass plants have ongoing costs for labor, routine maintenance, and ash disposal. Handling a solid, non-uniform fuel like biomass requires more complex machinery and more intensive maintenance than a gas-fired power plant, leading to higher operational expenses.

Comparing Biomass to Other Energy Sources

With the cost structure understood, we can make a more meaningful comparison to its main competitors.

vs. Fossil Fuels (Natural Gas & Coal)

For pure electricity generation at scale, natural gas and coal are typically cheaper than biomass. Their high energy density and established global supply chains give them a significant cost advantage. The primary argument for biomass over fossil fuels is not cost, but its potential to be a carbon-neutral energy source.

vs. Utility-Scale Solar & Wind

In the last decade, the Levelized Cost of Energy (LCOE) from new utility-scale solar and wind projects has plummeted, making them the cheapest sources of new electricity generation in many regions. On a pure cost-per-megawatt-hour basis for the grid, new biomass plants cannot compete with these intermittent renewables.

The Niche Advantage: Baseload Power

Where biomass holds a distinct advantage over solar and wind is its ability to provide dispatchable, baseload power. Like a fossil fuel plant, a biomass plant can run 24/7, regardless of whether the sun is shining or the wind is blowing. This reliability provides a stability service to the grid that intermittent renewables cannot offer alone.

Understanding the Trade-offs and Hidden Costs

Evaluating biomass requires looking beyond the raw numbers and considering the practical and economic constraints.

The "Local" Constraint

The economic model for biomass breaks down quickly as you move feedstock more than 50-100 miles. It is not a globally scalable solution like LNG or solar panels; it is a fundamentally local solution for local waste or resource streams.

The Subsidy Factor

Many biomass projects around the world are only economically viable due to government subsidies, tax credits, or renewable energy mandates. Without this financial support, they often fail to deliver a competitive return on investment compared to other energy sources.

Competing Uses for Feedstock

The price of biomass feedstock can be highly volatile. A sawmill's wood chips might be cheap one year, but if demand from the paper or particleboard industry rises, the price can spike, dramatically increasing the power plant's operating costs.

Making the Right Choice for Your Goal

The decision to use biomass should be driven by your primary objective, not a flawed search for the single "cheapest" energy.

- If your primary focus is the lowest possible grid electricity cost: Utility-scale solar, wind, and natural gas are your most cost-effective options for new generation.

- If your primary focus is industrial waste management: Co-locating a biomass-to-energy plant with an industrial facility (like a sawmill or food processor) can be an extremely economical way to create value from a waste stream.

- If your primary focus is reliable, carbon-neutral power: Biomass is a viable, though often more expensive, option for providing firm renewable energy that can balance the intermittency of solar and wind on the grid.

Ultimately, the cost of biomass energy is a puzzle solved by geography and logistics, not a simple price tag.

Summary Table:

| Cost Factor | Biomass Energy | Utility-Scale Solar/Wind | Natural Gas |

|---|---|---|---|

| Fuel Cost | High (varies locally) | Free (sun/wind) | Moderate (market-dependent) |

| Transportation | High (low energy density) | Low (modular components) | Low (pipelines) |

| Capital Cost (per kW) | $3,000 - $6,000+ | $1,000 - $1,500 | $1,000 - $1,300 |

| Grid Reliability | Baseload (24/7) | Intermittent (weather-dependent) | Baseload (24/7) |

| Best Use Case | Local waste streams, carbon-neutral baseload | Low-cost grid electricity | Low-cost, scalable power |

Ready to Optimize Your Lab’s Energy and Material Efficiency?

Choosing the right energy source is just one part of managing a modern laboratory. At KINTEK, we specialize in providing high-quality lab equipment and consumables that help you maximize efficiency, whether you're researching biomass conversion, analyzing fuel properties, or developing sustainable materials. Our products are designed to support precise, reliable, and cost-effective operations—helping you turn complex challenges into actionable results.

Let’s work together to power your progress. Contact our experts today to find the ideal solutions for your laboratory needs.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

People Also Ask

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions