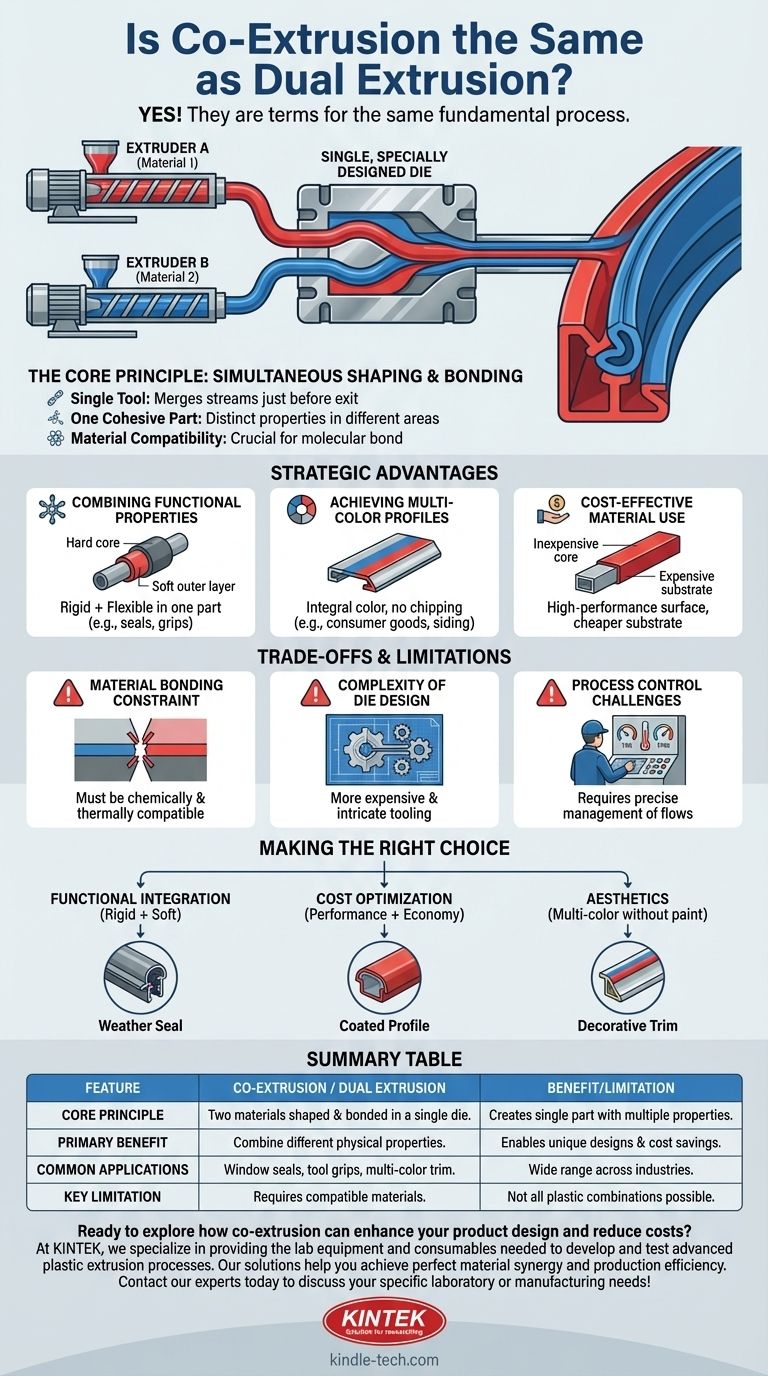

In the context of industrial plastics manufacturing, yes, co-extrusion and dual extrusion are terms for the same fundamental process. It describes a method where two different materials are fed through separate extruders into a single die, where they are joined together to form a single, unified profile or part.

While the terminology can be used interchangeably, the critical concept to grasp is the simultaneous shaping and bonding of two compatible materials within a single tool. This distinction is what unlocks unique design and cost-saving opportunities compared to other manufacturing methods.

How Co-Extrusion Works: The Core Principle

Co-extrusion is not simply gluing two finished pieces together. It is an elegant process that creates a molecular bond between materials as they are being formed, resulting in a single, integrated component with distinct properties in different areas.

The Role of the Single Die

The defining feature of co-extrusion is the use of a single, specially designed die. Two or more extruders push molten material into this die. The internal geometry of the die is engineered to merge these material streams just before they exit, forming them into the final desired shape.

Combining Materials into One Part

The output is not two parts, but one cohesive part. A classic example is weather stripping for a car door, which may have a rigid section for clipping onto the frame and a soft, flexible section for sealing. Co-extrusion creates this as a single piece.

The Critical Importance of Material Compatibility

The reference to bonding "like" materials is crucial. For co-extrusion to be successful, the materials must be chemically and thermally compatible. They need similar melting temperatures and flow characteristics so they can bond at a molecular level. An improper match will result in delamination and part failure.

Why Use Co-Extrusion? The Strategic Advantages

Engineers and designers specify co-extrusion to achieve performance or cost benefits that are impossible with a single material.

Combining Functional Properties

The most common application is to combine a rigid material with a flexible one. This allows for the creation of parts that have structural integrity in one area and softness or flexibility in another, such as tool grips, window seals, or living hinges.

Achieving Multi-Color Profiles

Co-extrusion is a highly efficient way to produce parts with multiple, distinct colors. Since the color is integral to the material, it cannot chip or wear away like paint. This is common in consumer goods, siding, and decorative trim.

Cost-Effective Material Use

This process allows for significant cost savings. A less expensive or recycled material can be used for the core or non-visible part of a profile, while a thin outer layer of a more expensive, high-performance material provides the necessary appearance, UV resistance, or chemical resistance.

Understanding the Trade-offs and Limitations

While powerful, co-extrusion is not a universal solution. It comes with specific technical challenges that must be managed.

The Constraint of Material Bonding

The requirement for material compatibility is the biggest limitation. A deep understanding of polymer science is necessary to select two materials that will form a permanent, reliable bond under processing conditions. Not all plastic combinations are possible.

Complexity of Die Design

A co-extrusion die is significantly more complex and expensive to design and manufacture than a single-material die. The upfront tooling investment is higher due to the intricate internal channels required to manage multiple material flows.

Process Control Challenges

Successfully running a co-extrusion line requires a high degree of expertise. Operators must precisely balance the temperatures, pressures, and flow rates of two different material streams to ensure a consistent cross-section and a strong bond throughout the production run.

Making the Right Choice for Your Goal

To decide if this process is right for your project, consider your primary objective.

- If your primary focus is functional integration: Co-extrusion is ideal for creating single parts that combine different physical properties, such as a rigid base with a soft seal.

- If your primary focus is cost optimization: Use this process to place expensive, high-performance materials only on the surfaces where they are needed, using a cheaper substrate for the bulk of the part.

- If your primary focus is aesthetics: This is a highly efficient way to produce durable, multi-colored parts without requiring secondary painting or assembly operations.

By understanding the principles of co-extrusion, you can design more efficient, functional, and cost-effective products by leveraging the power of material synergy.

Summary Table:

| Feature | Co-Extrusion / Dual Extrusion |

|---|---|

| Core Principle | Two materials are shaped and bonded in a single die. |

| Primary Benefit | Creates a single part with multiple properties (e.g., rigid + flexible). |

| Common Applications | Window seals, tool grips, multi-color trim, cost-effective profiles. |

| Key Limitation | Requires chemically and thermally compatible materials for a strong bond. |

Ready to explore how co-extrusion can enhance your product design and reduce costs? At KINTEK, we specialize in providing the lab equipment and consumables needed to develop and test advanced plastic extrusion processes. Our solutions help you achieve perfect material synergy and production efficiency. Contact our experts today to discuss your specific laboratory or manufacturing needs!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Anti-Cracking Press Mold for Lab Use

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- How do PECVD systems improve DLC coatings on implants? Superior Durability and Biocompatibility Explained

- What is the difference between plasma CVD and thermal CVD? Choose the Right Method for Your Substrate

- Can plasma enhanced CVD deposit metals? Why PECVD is rarely used for metal deposition

- What is the process of PECVD in semiconductor? Enabling Low-Temperature Thin Film Deposition

- Why does a PECVD vacuum system require both a rotary vane and turbo pump? Ensure High-Purity Coatings