Yes, numerous modern alternatives to traditional silver-colored dental caps exist. These options range from materials that perfectly mimic the look of a natural tooth, like porcelain and zirconia, to other metals like gold. The best choice for you depends on the tooth's location, your budget, and your aesthetic priorities.

The decision to move away from a silver-colored cap is no longer a trade-off between appearance and strength. Modern dental materials like zirconia offer exceptional durability while providing a natural, tooth-colored aesthetic, making them suitable for nearly any tooth in your mouth.

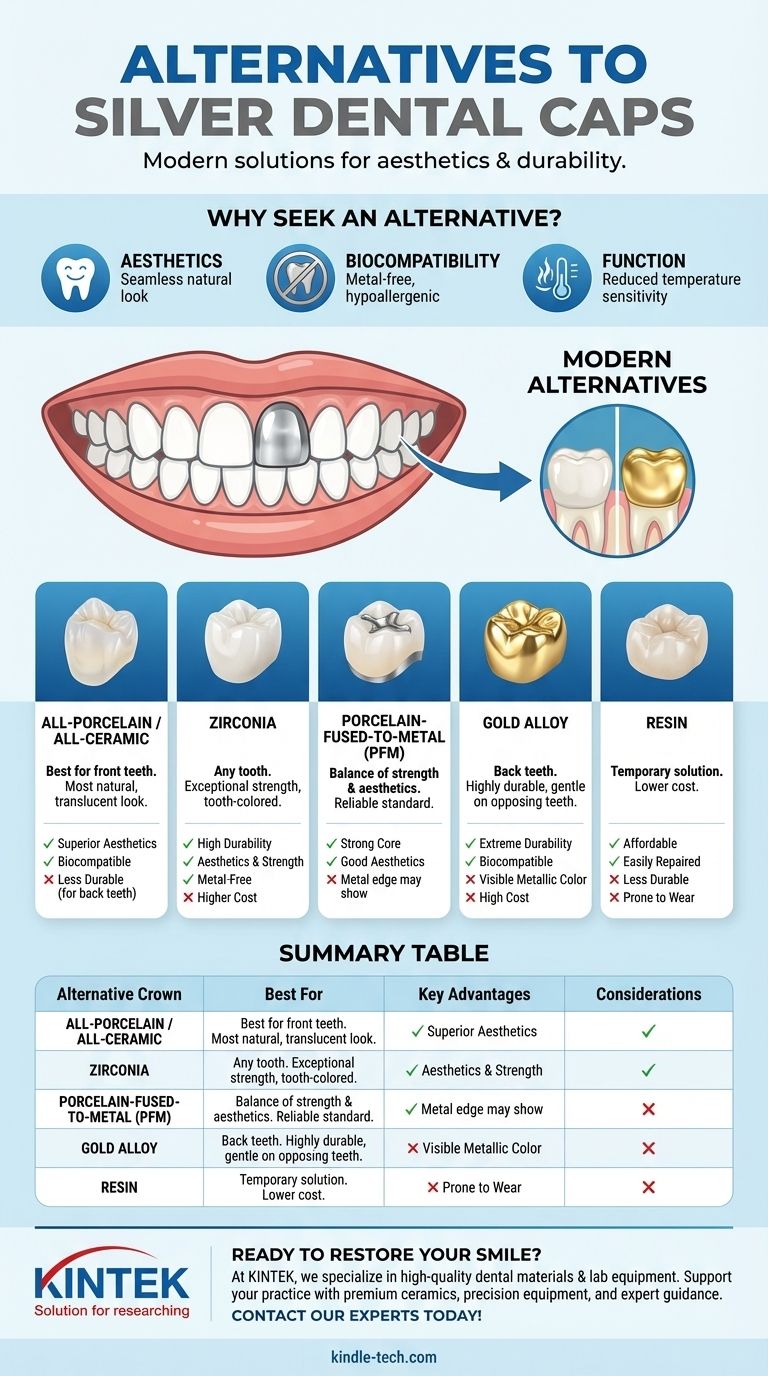

Why Seek an Alternative to Silver Caps?

While traditional metal alloy crowns are effective, patients often seek alternatives for a few key reasons. Understanding these motivations is the first step in choosing the right replacement.

The Obvious Aesthetic Concern

The primary driver is appearance. A metallic crown, especially one visible when you smile or talk, stands out against natural teeth. Patients desire a seamless, natural-looking smile that non-metallic options can provide.

Material and Biocompatibility

Some individuals have allergies or sensitivities to the metals (like nickel or chromium) used in traditional silver-colored crowns. Others simply prefer to have metal-free restorations in their mouths for peace of mind.

Functional Drawbacks

Metal is an excellent conductor of temperature. This can sometimes lead to increased sensitivity to hot and cold foods and drinks, an issue that is significantly reduced with materials like ceramic or zirconia.

Modern Alternatives to Metal Crowns

Dentistry now offers a wide array of materials, each with a unique profile of strength, aesthetics, and cost.

All-Porcelain or All-Ceramic Crowns

These provide the best and most natural-looking aesthetic. Because they are translucent, they mimic the appearance of natural tooth enamel better than any other material. They are an excellent choice for front teeth.

Zirconia Crowns

Zirconia is a type of ceramic that is exceptionally strong and durable. It combines the strength of metal with the aesthetics of porcelain, making it a fantastic, tooth-colored option for any tooth in the mouth, including back molars that endure heavy chewing forces.

Porcelain-Fused-to-Metal (PFM) Crowns

PFM crowns have a metal substructure with a layer of porcelain fused to the exterior. They offer a good balance of strength from the metal core and decent aesthetics from the porcelain outer shell. They have been a reliable standard for decades.

Gold Alloy Crowns

Though not tooth-colored, gold remains a gold-standard material. It is extremely durable, highly biocompatible, and very gentle on the opposing teeth it chews against. Its primary drawback is its highly visible metallic color and cost.

Resin Crowns

Composite resin crowns are a less expensive option. However, they are not as strong or durable as porcelain or metal crowns and are more prone to wear and fracture over time. They are often considered a more temporary solution.

Understanding the Trade-offs

Choosing a crown is not just about picking a material; it's about balancing competing factors. A discussion with your dentist is critical.

Durability vs. Aesthetics

Historically, the strongest materials (metal, gold) were the least aesthetic. While this is no longer strictly true thanks to zirconia, there are still nuances. All-porcelain crowns offer the absolute best look but are more brittle than zirconia or gold.

Location Is Key: Front vs. Back Teeth

The decision is heavily influenced by the tooth's location.

- Front Teeth: Aesthetics are paramount. All-porcelain or highly translucent zirconia are the top choices.

- Back Teeth: Strength is the priority. Zirconia, PFM, and gold alloy crowns are ideal for handling the immense forces of chewing.

The PFM Compromise

Porcelain-fused-to-metal crowns are a good middle ground, but they have a specific downside. Over time, the gum line can recede, exposing the dark metal edge of the crown, which can be a cosmetic concern.

Cost and Longevity

Cost varies significantly. Generally, resin is the least expensive, followed by metal and PFM. Zirconia, all-porcelain, and gold are typically the most expensive options, but they also offer exceptional longevity when cared for properly.

Making the Right Choice for Your Goal

Consult with your dental professional to evaluate your specific clinical situation, but use these points to guide your conversation.

- If your primary focus is the most natural look for a front tooth: An all-porcelain or all-ceramic crown is your best choice for its superior aesthetics.

- If your primary focus is maximum durability for a back molar: A zirconia or gold alloy crown provides the best long-term strength and resistance to fracture.

- If your primary focus is a balance of strength and good looks anywhere in the mouth: A zirconia crown is the modern standard that excels in both categories.

- If your primary focus is biocompatibility and being gentle on opposing teeth: A gold alloy crown is an outstanding, albeit highly visible, clinical option.

Ultimately, the best crown is one that restores the tooth's function, fits your aesthetic goals, and is placed with expert precision by your dentist.

Summary Table:

| Alternative Crown | Best For | Key Advantages | Considerations |

|---|---|---|---|

| All-Porcelain/Ceramic | Front Teeth | Most natural, translucent look | Less durable than zirconia for back teeth |

| Zirconia | Any Tooth (Front/Back) | Excellent strength, tooth-colored | Higher cost than metal/PFM |

| Porcelain-Fused-to-Metal (PFM) | Balance of Strength & Aesthetics | Reliable, metal core with porcelain shell | May show metal edge if gums recede |

| Gold Alloy | Back Teeth | Highly durable, gentle on opposing teeth | Visible metallic color, high cost |

| Resin | Temporary Solution | Lower cost | Less durable, prone to wear/fracture |

Ready to restore your smile with a crown that balances strength and aesthetics?

At KINTEK, we specialize in high-quality dental materials and lab equipment trusted by dental professionals worldwide. Whether you're a dentist seeking reliable zirconia blocks or a lab technician crafting precise porcelain crowns, our products ensure exceptional results for your patients.

Let us support your practice with:

- Premium dental ceramics and alloys for durable, natural-looking restorations

- Precision lab equipment for consistent crown fabrication

- Expert guidance on material selection for front or back teeth cases

Elevate your dental restorations — contact our experts today to discuss your specific needs!

Visual Guide

Related Products

- Graphite Vacuum Furnace Negative Material Graphitization Furnace

- 1200℃ Muffle Furnace Oven for Laboratory

- Horizontal High Temperature Graphite Vacuum Graphitization Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Large Vertical Graphite Vacuum Graphitization Furnace

People Also Ask

- What are the disadvantages of biomass conversion? High Costs, Logistical Hurdles, and Environmental Trade-offs

- What is the difference between oxidizing and reducing environments? Key Insights for Chemical Reactions

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are some positive and negative environmental effects of using biomass? A Balanced Look at a Renewable Energy Source

- What are the key differences between incineration and gasification? Explore Waste Management Solutions