For most scientific applications, yes, glassware is autoclaved, but this simple answer hides critical details. Autoclaving is the gold standard for sterilization, not cleaning, and it is only safe for specific types of glassware. Using the wrong glass or the wrong process can lead to equipment damage, failed experiments, and serious safety hazards.

The decision to autoclave glassware is not a question of cleaning, but of sterilization. The correct choice depends entirely on two factors: the type of glass you are using and whether your application requires the complete elimination of all microbial life.

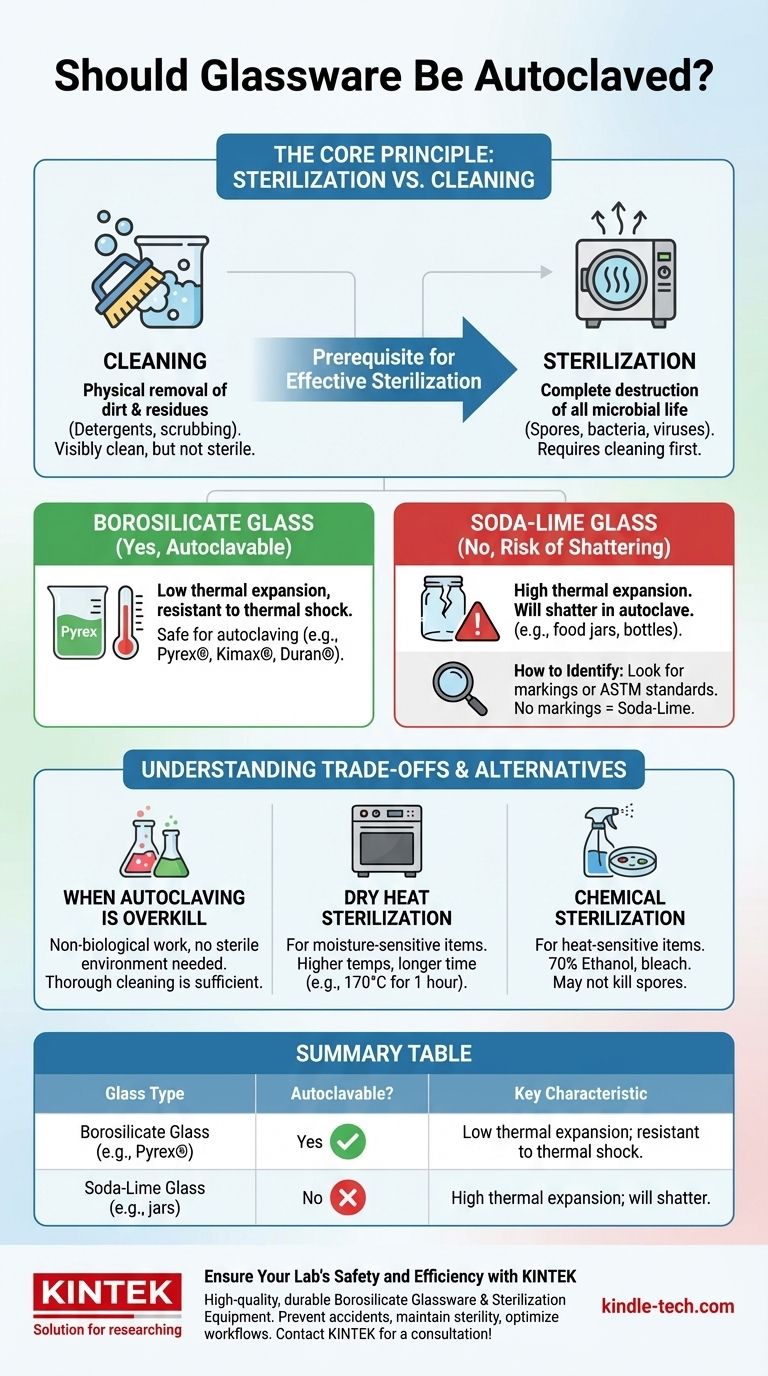

The Core Principle: Sterilization vs. Cleaning

Before proceeding, it is essential to distinguish between cleaning and sterilizing. These terms are not interchangeable, and confusing them is the root of most procedural errors.

What is Cleaning?

Cleaning is the physical removal of foreign material, like soil, organic residues, and chemical precipitates. It is accomplished with detergents, solvents, and scrubbing. A piece of glassware can be visibly clean but still covered in invisible microorganisms.

What is Sterilization?

Sterilization is the complete destruction or removal of all forms of microbial life, including bacteria, viruses, fungi, and highly resistant bacterial spores. Cleaning is a mandatory prerequisite for effective sterilization, as residual dirt can shield microbes from the sterilizing agent.

Why Autoclaving Excels at Sterilization

An autoclave does not simply heat items. It uses pressurized saturated steam (typically at 121°C / 250°F and 15 psi) to kill microorganisms. The moist heat is extremely effective at penetrating materials and denaturing the essential proteins and enzymes that microbes need to survive.

Not All Glass Is Created Equal

The intense temperature and pressure changes inside an autoclave will destroy the wrong type of glassware. This is the most critical safety consideration.

Borosilicate Glass: The Gold Standard

Most laboratory glassware is made from borosilicate glass (e.g., Pyrex®, Kimax®, Duran®). This glass has a very low coefficient of thermal expansion, meaning it does not expand or contract much when heated or cooled. This property makes it highly resistant to thermal shock and safe for autoclaving.

Soda-Lime Glass: The Risk of Thermal Shock

Standard consumer glassware, such as food jars, beverage bottles, or window panes, is typically made of soda-lime glass. This type has a much higher coefficient of thermal expansion. The rapid temperature change during an autoclave cycle will cause it to shatter violently.

How to Identify Your Glassware

Look for markings on the glass itself. Laboratory-grade borosilicate glass is almost always marked with the manufacturer's name (Pyrex, Kimax) or an ASTM standard (like ASTM E438). If there are no markings, assume it is soda-lime glass and do not autoclave it.

Understanding the Trade-offs and Alternatives

Autoclaving is powerful, but it is not the only option and is sometimes unnecessary. Understanding the context of your work is key.

When Autoclaving is Overkill

If your work does not involve biological materials and does not require a sterile environment (e.g., many inorganic chemistry procedures, preparing standard solutions), then thorough cleaning is sufficient. Autoclaving in these cases wastes time, energy, and resources.

Alternative: Dry Heat Sterilization

For materials that are sensitive to moisture but can withstand high temperatures (like powders or oils), dry heat sterilization is used. This process requires higher temperatures (e.g., 170°C for 1 hour) and longer times because dry heat is less efficient at transferring energy than moist heat. It is suitable for borosilicate glassware but not for soda-lime glass.

Alternative: Chemical Sterilization

For items that are sensitive to heat, chemical methods can be used. Rinsing with a 70% ethanol solution can sanitize surfaces, and soaking in a dilute bleach solution can also be effective, though it must be followed by thorough rinsing with sterile water. These methods may not achieve the same complete spore-killing sterility as an autoclave.

Making the Right Choice for Your Goal

Select your method based on your objective. The goal is to achieve the necessary level of cleanliness or sterility safely and efficiently.

- If your primary focus is sterility for microbiology, cell culture, or medical applications: You must autoclave your borosilicate glassware after thoroughly cleaning it.

- If your primary focus is general chemical preparation without biological components: A rigorous cleaning protocol with appropriate detergents and rinses is sufficient.

- If you need to sterilize heat-sensitive or non-autoclavable items: You must use validated alternatives like chemical sterilization or sterile filtration.

By matching your sterilization method to your glassware and your scientific goal, you ensure both safety and the integrity of your results.

Summary Table:

| Glass Type | Autoclavable? | Key Characteristic |

|---|---|---|

| Borosilicate Glass (e.g., Pyrex®) | Yes | Low thermal expansion; resistant to thermal shock. |

| Soda-Lime Glass (e.g., jars, bottles) | No | High thermal expansion; will shatter in an autoclave. |

Ensure Your Lab's Safety and Efficiency with KINTEK

Choosing the right glassware and sterilization method is critical for the safety of your personnel and the success of your experiments. KINTEK specializes in providing high-quality, durable borosilicate glassware and the equipment you need for reliable autoclaving and other sterilization processes.

We help you:

- Prevent accidents: Ensure you are using the correct, autoclavable glassware.

- Maintain sterility: Achieve consistent, reliable results in microbiology and cell culture.

- Optimize workflows: Get the right tools for your specific application, from general chemistry to advanced biological research.

Don't risk equipment failure or compromised results. Let our experts help you select the perfect lab equipment for your needs.

Contact KINTEK today for a consultation and enhance your laboratory's capabilities!

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

People Also Ask

- What are the advantages and disadvantages of sterilization with an autoclave? Achieve Reliable Sterilization for Your Lab

- What is the role of a Teflon-lined autoclave in g-C3N4 synthesis? Achieve High-Purity Hydrothermal Condensation

- What are 2 functions of an autoclave? Achieve Complete Sterilization and Decontamination

- What are the pros and cons of autoclave? Unlock Fast, Economical Sterilization

- What is the role of a high-pressure autoclave in hydrothermal synthesis? Unlock Precision Metal Oxide Nanomaterials

- What are the three types of sterilizers? Choose the Right Method for Your Lab

- What is the function of a high-pressure Autoclave in the alkaline leaching process of scheelite? Maximize Tungsten Yield

- How are high-pressure autoclaves or high-temperature laboratory furnaces used to test green flame retardant stability?