When selecting an ultra-low temperature (ULT) freezer, the most critical features go far beyond simply reaching a low setpoint. To ensure the long-term viability of your samples, you must prioritize a combination of precise temperature control, robust alarming systems, features that maintain stability during daily use, and accurate data-logging capabilities. These elements work together to protect your invaluable biological materials from degradation.

The best ULT freezer is not just the one that gets the coldest, but the one that maintains that temperature with maximum stability, efficiency, and reliability. Your decision should balance the core need for absolute sample protection against the practical realities of your laboratory's budget, space, and daily workflow.

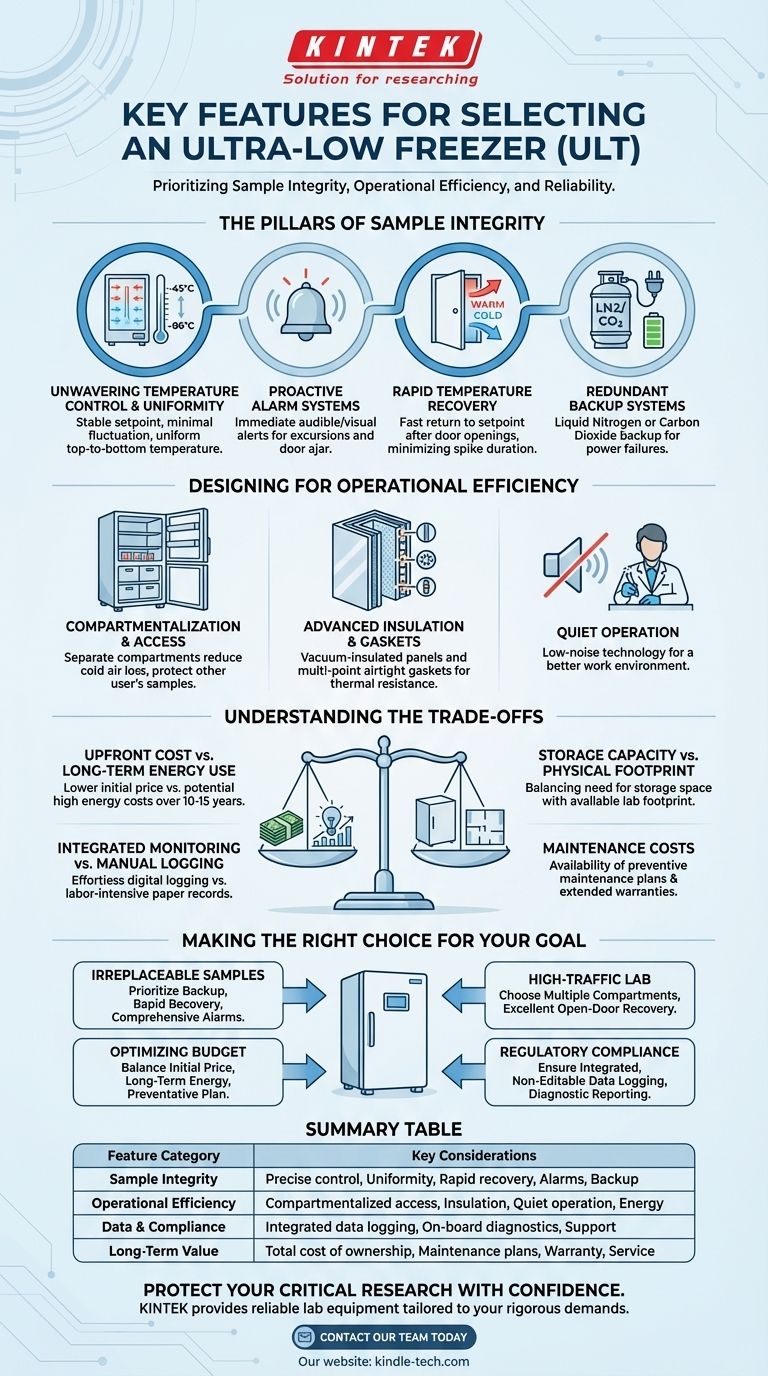

The Pillars of Sample Integrity

Your primary goal is to protect your samples. The freezer's core performance features are non-negotiable and directly contribute to this mission.

Unwavering Temperature Control & Uniformity

A ULT freezer's main purpose is to maintain a stable environment, typically between -45°C and -86°C. Precise temperature control ensures the setpoint is held with minimal fluctuation.

Equally important is temperature uniformity, which guarantees that the temperature at the top of the freezer is the same as the bottom. Inconsistent temperatures can put samples in different locations at risk.

Proactive Alarm Systems

Temperature excursion alarms are your first line of defense against equipment failure or an improperly closed door. These systems provide immediate audible and visual alerts when the internal temperature deviates from the set range, allowing you to intervene before samples are compromised.

Rapid Temperature Recovery

Every time the door is opened, warm, moist air enters the freezer, causing the internal temperature to rise. A freezer with excellent open-door recovery uses a powerful refrigeration system to quickly return to its setpoint, minimizing the duration and impact of this temperature spike.

Redundant Backup Systems

For truly irreplaceable samples, a backup system is essential. These systems, often using liquid nitrogen (LN2) or carbon dioxide (CO2), automatically engage during a power failure to keep the chamber cold for an extended period. This is an insurance policy for your research.

Designing for Operational Efficiency

Beyond sample protection, a freezer must be practical for daily use in a busy lab environment. These features impact your budget, workflow, and workplace environment.

Compartmentalization and Access

Upright freezers with separate internal compartments or inner doors are highly advantageous. When you open the main door, you only need to open one small inner door, dramatically reducing cold air loss and protecting the samples of other users in a shared freezer.

Advanced Insulation and Gaskets

The efficiency of a freezer is largely determined by its insulation and door gaskets. Modern vacuum-insulated panels provide superior thermal resistance in a thin profile, while multi-bulb gaskets create multiple points of contact for an airtight seal, reducing energy consumption.

Quiet Operation

ULT freezers can be loud, which is a significant factor in a lab where concentration is key. Look for models engineered with low-noise technology to improve the quality of the work environment.

Understanding the Trade-offs

Selecting a ULT freezer involves balancing competing priorities. Understanding these trade-offs is key to making a well-informed decision.

Upfront Cost vs. Long-Term Energy Use

A lower-priced freezer may seem like a good deal, but it often comes with higher energy consumption. Over the freezer's 10- to 15-year lifespan, a more expensive but highly efficient model can result in a lower total cost of ownership due to significant electricity savings.

Storage Capacity vs. Physical Footprint

You must balance the storage capacity you need with the available space in your lab. Upright models offer the most storage for their footprint, while chest freezers, though bulkier, tend to hold their temperature better when opened.

Integrated Monitoring vs. Manual Logging

Modern freezers often feature on-board diagnostics and integrated digital data logging. This provides effortless and accurate record-keeping for regulatory compliance. The alternative is a traditional paper chart recorder, which is less precise and requires more manual effort.

The Hidden Costs of Maintenance

A freezer is a mechanical device that will eventually require service. Consider the availability of preventive maintenance plans and extended warranties. A robust service plan can prevent costly downtime and emergency repairs.

Making the Right Choice for Your Goal

Your final decision should be guided by your lab's unique priorities.

- If your primary focus is irreplaceable samples: Prioritize robust backup systems, rapid temperature recovery, and comprehensive alarm monitoring.

- If your primary focus is optimizing your budget: Balance the initial purchase price with long-term energy consumption ratings and the cost of a preventative maintenance plan.

- If your primary focus is a high-traffic, shared lab: Choose a model with multiple internal compartments and excellent open-door recovery to minimize temperature disruption.

- If your primary focus is regulatory compliance: Ensure the freezer has integrated, non-editable data logging and clear diagnostic reporting capabilities.

By carefully evaluating these features against your specific needs, you can select a freezer that serves as a reliable foundation for your critical work.

Summary Table:

| Feature Category | Key Considerations |

|---|---|

| Sample Integrity | Precise temperature control, uniformity, rapid recovery, proactive alarms, backup systems |

| Operational Efficiency | Compartmentalized access, advanced insulation, quiet operation, energy consumption |

| Data & Compliance | Integrated data logging, on-board diagnostics, regulatory compliance support |

| Long-Term Value | Total cost of ownership, maintenance plans, warranty, service support |

Protect your critical research with confidence. The right ultra-low freezer is a long-term investment in your lab's success. At KINTEK, we specialize in providing reliable lab equipment, including ULT freezers, tailored to meet the rigorous demands of laboratory environments. Our experts can help you select a model that balances sample protection, energy efficiency, and compliance needs for your specific workflow.

Let's find the perfect ULT freezer for your lab. Contact our team today for a personalized consultation and discover how KINTEK supports your laboratory's most vital work.

Visual Guide

Related Products

- 158L Precision Vertical Ultra Low Freezer for Laboratory Applications

- 938L Vertical Ultra Low Temperature Freezer for Advanced Laboratory Storage

- 108L Vertical Ultra Low Temperature ULT Freezer

- 408L Advanced Vertical Laboratory Ultra Low Temperature Freezer for Critical Research Material Preservation

- 808L Precision Laboratory Vertical Ultra Low Temperature Freezer

People Also Ask

- How are advancements in compressor technology and refrigerant fluids improving ULT freezers? Boost Efficiency & Cut Costs

- How should frost be removed from Ultra-Low Temperature Freezers? Protect Your Samples and Equipment

- What is the purpose of ultra-low temperature (ULT) freezers? Preserve Critical Biological Samples

- What types of materials are commonly stored in ultra low temperature freezers? Preserving Cells, Vaccines & Biomolecules

- Why are ULT freezers considered vital equipment in labs? Ensuring Uncompromised Sample Integrity for Critical Research